ST-20 specifications

The Honeywell ST-20 is an advanced temperature and humidity data logger designed for monitoring environmental conditions in various settings, including laboratories, warehouses, and production facilities. Known for its reliability and accuracy, the ST-20 combines cutting-edge technology with user-friendly features, making it an essential tool for professionals in need of real-time data collection.One of the standout features of the Honeywell ST-20 is its dual-channel capability, which allows it to monitor both temperature and humidity simultaneously. This dual functionality makes it particularly useful in environments where both factors significantly impact product quality, such as in pharmaceuticals or food storage. The device is equipped with a wide temperature range, typically spanning from -40°C to +70°C, with exceptional accuracy levels, ensuring precise readings.

The ST-20 boasts a robust data storage capacity, capable of recording thousands of data points over extended periods. This extensive storage capacity enables users to continuously monitor conditions without the need for frequent data downloads. The built-in LCD screen provides real-time visibility into current conditions, making it easy for users to quickly assess environmental parameters at a glance.

The device employs Honeywell’s proprietary sensor technology, which enhances responsiveness and accuracy. Its sensors are designed to minimize drift and ensure reliable performance over time. Furthermore, the ST-20 features a user-friendly interface, allowing for easy configuration of measurement intervals and alarm thresholds through intuitive buttons. Users can set up alerts for both upper and lower limits, ensuring that corrective actions can be taken promptly when conditions deviate from specified ranges.

Wireless connectivity is another significant characteristic of the ST-20. It supports various communication protocols, allowing data to be transmitted seamlessly to cloud-based platforms or local servers for further analysis. This feature facilitates real-time monitoring and enables users to access data remotely, providing flexibility and enhancing operational efficiency.

Another notable aspect of the Honeywell ST-20 is its compact, rugged design. Built to withstand challenging environments, the device is resistant to dust and water ingress, making it suitable for both indoor and outdoor applications. The long battery life ensures extended operation without frequent interruptions, further enhancing its practicality.

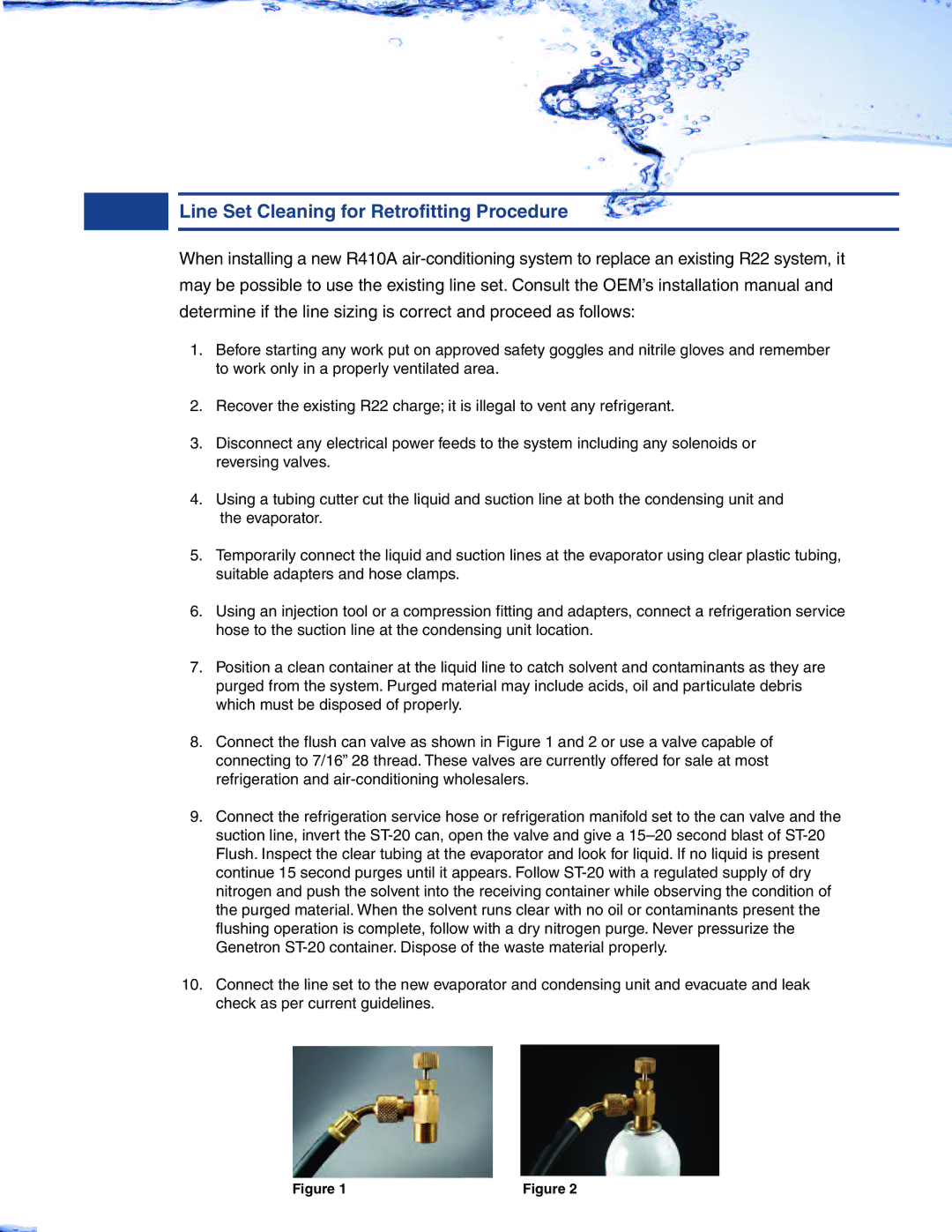

Overall, the Honeywell ST-20 is a sophisticated yet accessible data logger that meets the demands of various industries by providing accurate and reliable temperature and humidity monitoring. With its advanced features and user-friendly design, it is an indispensable tool for maintaining optimal environmental conditions and ensuring product integrity.