KML-451MWH, KML-451MAH specifications

The Hoshizaki KML-451MWH and KML-451MAH are high-performance commercial ice makers designed to meet the demanding needs of various foodservice establishments, including restaurants, cafes, and bars. These machines have established a reputation for reliability, efficiency, and superior ice production, making them essential assets for any operation needing consistent ice supply.One of the standout features of the Hoshizaki KML-451MWH and KML-451MAH is their unique crescent-shaped ice production. This type of ice is not only aesthetically pleasing but also has superior cooling properties, enabling it to chill beverages rapidly without diluting them too quickly. The machines are capable of producing up to 450 pounds of ice per day, ensuring that businesses can keep up with high demand during peak hours.

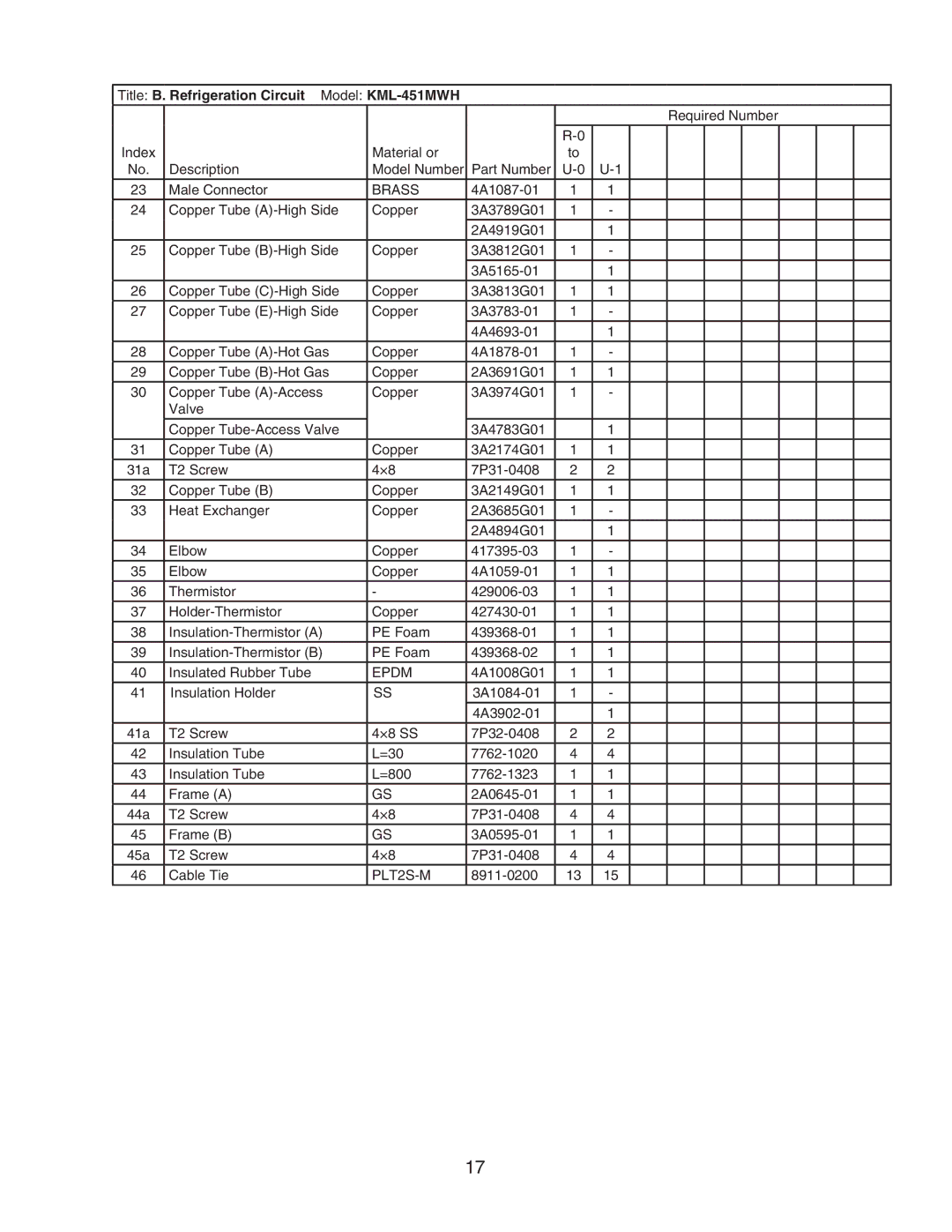

These ice makers are equipped with advanced technologies that enhance their performance and efficiency. The KML series incorporates a durable stainless steel construction, which ensures longevity and resistance to corrosion, making it ideal for heavy usage environments. Additionally, the internal components are designed for ease of maintenance, allowing for quick access during servicing.

The machines utilize a unique air-cooling system that enhances energy efficiency, reducing energy consumption while maintaining optimal ice production levels. The KML-451MWH features a built-in water filtration system that improves water quality and extends the lifespan of the ice maker by minimizing mineral buildup. This feature is particularly important in areas with hard water, as it helps prevent issues that can arise from poor water quality.

Another notable aspect of the KML-451MWH and KML-451MAH is their intuitive control panel, which offers ease of operation and monitoring. The LED indicators provide real-time updates on the ice-making process, ensuring that users are always informed about the machine's status. Additionally, these models come equipped with a self-diagnostic system that alerts operators to any potential issues, thereby minimizing downtime and preventing costly repairs.

In conclusion, the Hoshizaki KML-451MWH and KML-451MAH are exemplary ice makers that combine innovative technology, robust construction, and efficient operation. Their ability to produce high volumes of quality ice consistently makes them a reliable choice for any commercial setting focused on delivering exceptional customer service. By investing in a Hoshizaki ice maker, businesses can enhance their operational efficiency and ensure they always have ice on hand when needed.