INSTALLATION

Use the following procedure to relieve spring tension prior to cable or spring replacement.

!WARNING

DO NOT insert hands into gearbox until springs are fully

detensioned. Doing so could lead to serious injury.

1.Cycle reel thru normal operating cycle and stop when maximum amount of cable is wound onto reel spool.

2.Set spool lock to prevent spool from turning.

3.Remove access cover from top of gearbox.

4.Using open end wrench, loosen large hex nut slowly to allow springs to unwind. Fully loosen nut further with wrench until springs are completely unwound.

5.Repair reel or replace springs or cable as necessary.

6.Retighten nut until definite resistance is felt and spring washers are full compressed (flat). Replace cover.

NOTE: If hex nut is not adequately tightened, spring unwinding can occur during reel operation.

7. Pretension reel. See INSTALLATION section, front page.

CABLE REMOVAL

Use the following procedure to remove worn or damaged cable from reel prior to installation of new cable.

!CAUTION

Failure to relieve all spring tension prior to removing

cable could result in damage to equipment or personal injury. Follow instructions carefully.

1.Move machine serviced by reel to a position closest to reel. Springs will still be under

2.Turn off all electric power.

3.Using spool lock. lock spool to prevent turning.

4.Disconnect cable from machine junction box.

5.Detension springs as described above.

6.Remove cable from spool. Loosen cable clamp and

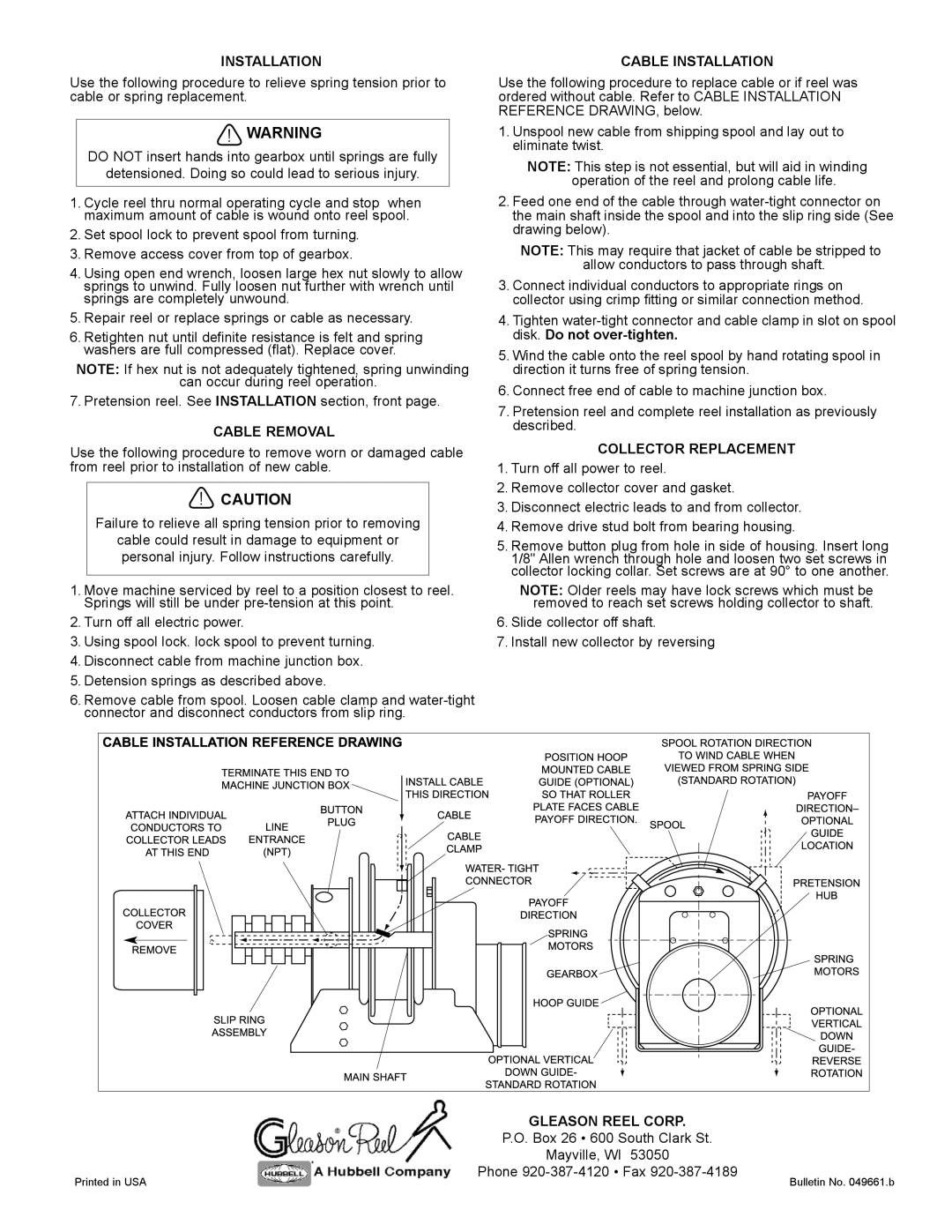

CABLE INSTALLATION

Use the following procedure to replace cable or if reel was ordered without cable. Refer to CABLE INSTALLATION REFERENCE DRAWING, below.

1.Unspool new cable from shipping spool and lay out to eliminate twist.

NOTE: This step is not essential, but will aid in winding operation of the reel and prolong cable life.

2.Feed one end of the cable through

NOTE: This may require that jacket of cable be stripped to allow conductors to pass through shaft.

3.Connect individual conductors to appropriate rings on collector using crimp fitting or similar connection method.

4.Tighten

5.Wind the cable onto the reel spool by hand rotating spool in direction it turns free of spring tension.

6.Connect free end of cable to machine junction box.

7.Pretension reel and complete reel installation as previously described.

COLLECTOR REPLACEMENT

1.Turn off all power to reel.

2.Remove collector cover and gasket.

3.Disconnect electric leads to and from collector.

4.Remove drive stud bolt from bearing housing.

5.Remove button plug from hole in side of housing. Insert long 1/8" Allen wrench through hole and loosen two set screws in collector locking collar. Set screws are at 90° to one another.

NOTE: Older reels may have lock screws which must be removed to reach set screws holding collector to shaft.

6.Slide collector off shaft.

7.Install new collector by reversing

Printed in USA

GLEASON REEL CORP.

P.O. Box 26 • 600 South Clark St.

Mayville, WI 53050

Phone

Bulletin No. 049661.b