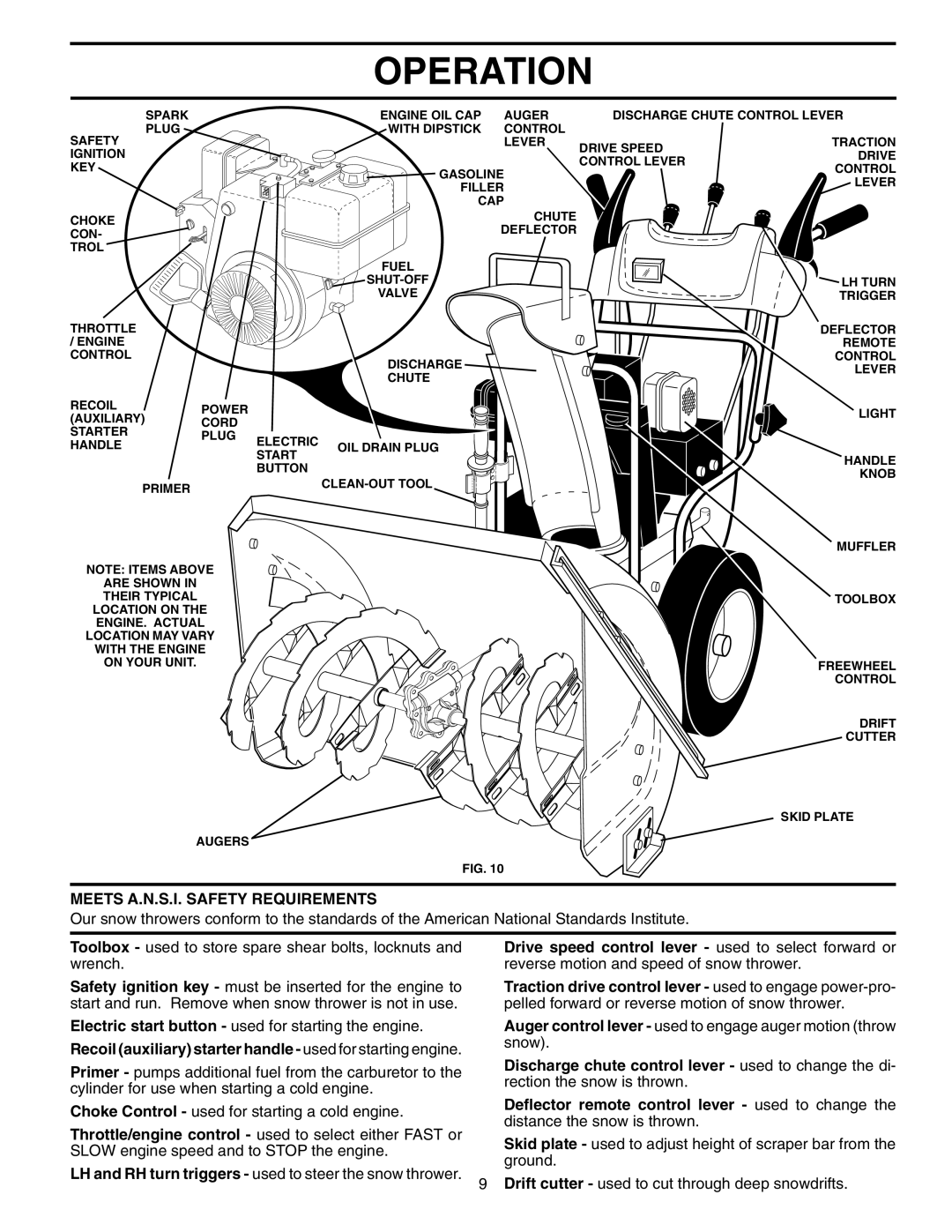

OPERATION

SPARK PLUG

ENGINE OIL CAP | AUGER |

WITH DIPSTICK | CONTROL |

DISCHARGE CHUTE CONTROL LEVER

SAFETY

IGNITION

KEY

CHOKE

CON-

TROL

THROTTLE

/ENGINE

CONTROL

RECOILPOWER

(AUXILIARY) CORD

STARTERPLUG HANDLE

PRIMER

NOTE: ITEMS ABOVE

ARE SHOWN IN

THEIR TYPICAL

LOCATION ON THE

ENGINE. ACTUAL

LOCATION MAY VARY

WITH THE ENGINE

ON YOUR UNIT.

ELECTRIC START BUTTON

LEVER |

GASOLINE

FILLER

CAP

CHUTE

DEFLECTOR

FUEL

![]()

VALVE

DISCHARGE ![]()

CHUTE

OIL DRAIN PLUG

DRIVE SPEED CONTROL LEVER

TRACTION DRIVE CONTROL LEVER

![]() LH TURN TRIGGER

LH TURN TRIGGER

DEFLECTOR REMOTE CONTROL LEVER

LIGHT

HANDLE

KNOB

MUFFLER

TOOLBOX

FREEWHEEL CONTROL

DRIFT

CUTTER

AUGERS

FIG. 10

SKID PLATE

MEETS A.N.S.I. SAFETY REQUIREMENTS

Our snow throwers conform to the standards of the American National Standards Institute.

Toolbox - used to store spare shear bolts, locknuts and wrench.

Safety ignition key - must be inserted for the engine to start and run. Remove when snow thrower is not in use.

Electric start button - used for starting the engine.

Recoil (auxiliary) starter handle - used for starting engine.

Primer - pumps additional fuel from the carburetor to the cylinder for use when starting a cold engine.

Choke Control - used for starting a cold engine.

Throttle/engine control - used to select either FAST or SLOW engine speed and to STOP the engine.

LH and RH turn triggers - used to steer the snow thrower.

Drive speed control lever - used to select forward or reverse motion and speed of snow thrower.

Traction drive control lever - used to engage

Auger control lever - used to engage auger motion (throw snow).

Discharge chute control lever - used to change the di- rection the snow is thrown.

Deflector remote control lever - used to change the distance the snow is thrown.

Skid plate - used to adjust height of scraper bar from the ground.

9 Drift cutter - used to cut through deep snowdrifts.