254XP, 257, 262XP, 354XP, 257, 262XP specifications

Husqvarna is a well-respected name in the world of outdoor power equipment, especially when it comes to chainsaws. Among its lineup, the models 254XP, 257, 262XP, and 354XP stand out for their robust performance and innovative technologies, catering to both professional and amateur users.The Husqvarna 254XP is known for its high power-to-weight ratio, making it a favorite among professionals who require portability without sacrificing performance. It features a 2.3 kW engine, providing ample power for a variety of cutting tasks. The chainsaw is equipped with a robust air injection system that removes larger debris before it reaches the air filter, helping to maintain engine performance and extend service intervals.

Similar to the 254XP, the Husqvarna 257 offers strong performance, but with enhancements tailored for even greater efficiency. It boasts an efficient combustion system, ensuring lower fuel consumption and reduced emissions, making it environmentally friendly. Another standout feature is the LowVib technology, which minimizes vibrations, making it easier for operators to work for extended periods without fatigue.

The Husqvarna 262XP takes a step further in terms of power and efficiency, featuring a 3.2 kW engine. This model is designed for heavy-duty tasks and is appreciated in the logging industry. Its advanced ignition system ensures quick starts and stable operation, even in challenging conditions. The X-Torq engine technology reduces fuel consumption and emissions, making it a green choice for professionals.

The 354XP is engineered for those who require a balance of power and weight. With a cutting capacity that satisfies both casual users and professionals, it delivers 2.9 kW of power. The chainsaw’s design incorporates features like the automatic chain lubrication system, ensuring optimal oil flow to the bar and chain, which prolongs their lifespan.

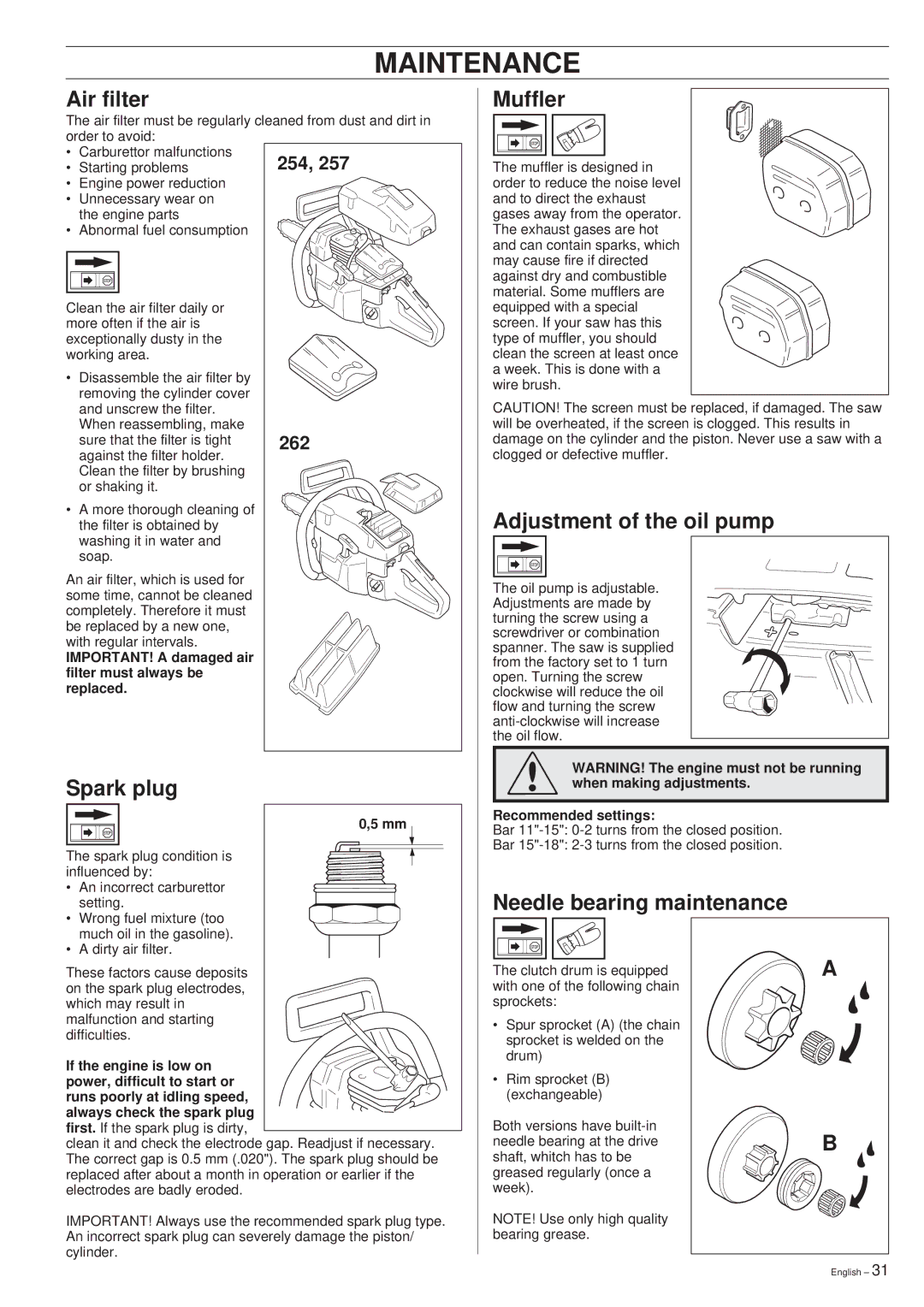

In terms of ergonomics, all these models come with comfort-grip handles and adjustable oil pumps, allowing for ease of use and control during operation. Their starting mechanisms are user-friendly, often featuring a decompression valve for easier pull starts.

These Husqvarna models exemplify the brand's commitment to merging power, efficiency, and user comfort. Whether tackling small projects or heavy-duty logging, the 254XP, 257, 262XP, and 354XP offer dependable solutions that meet the demands of today’s users.