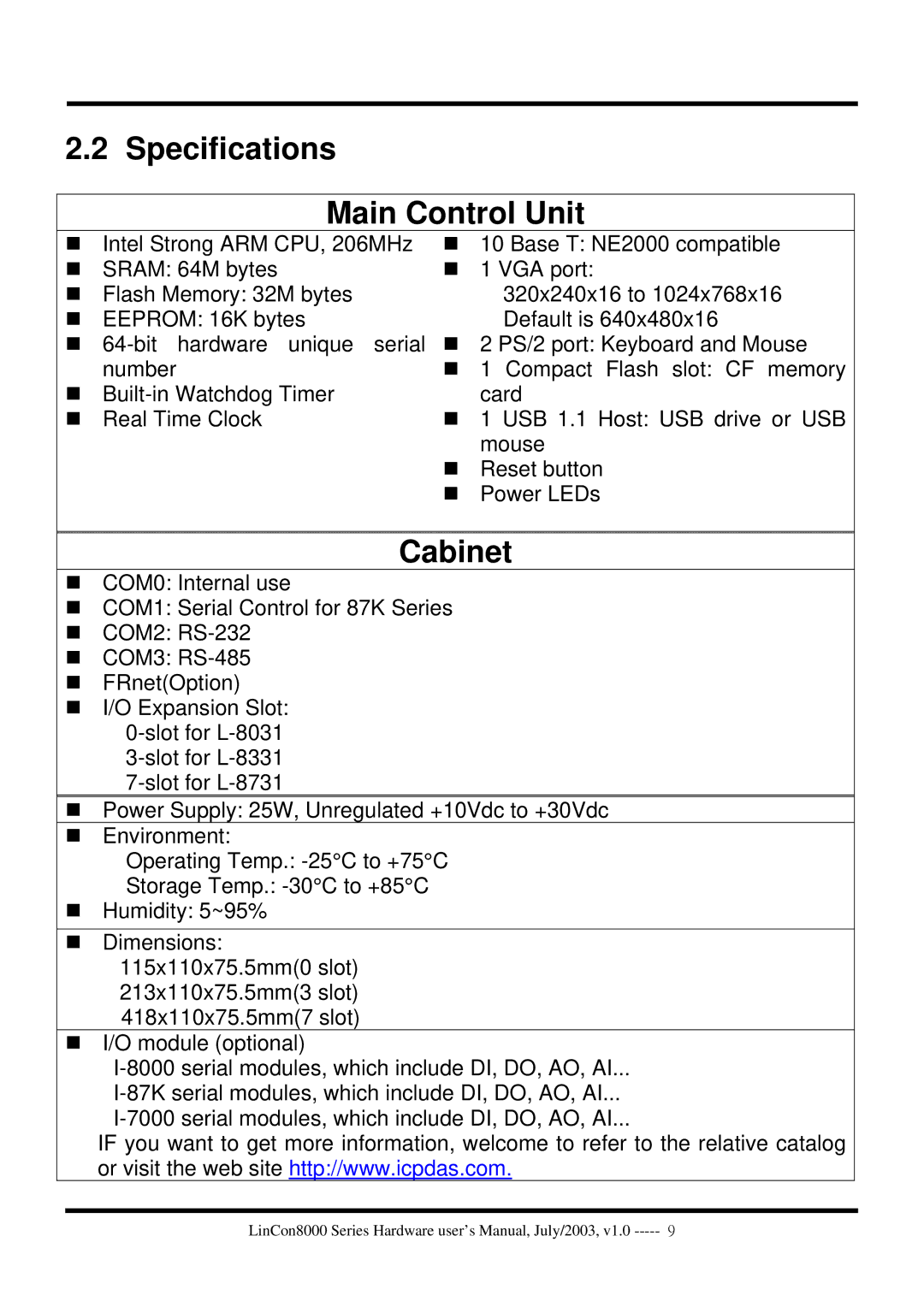

LinCon-8000 specifications

The ICP DAS USA LinCon-8000 is a powerful and versatile device designed for remote data acquisition and control applications. Utilizing advanced communication technologies, it caters to the demands of modern industrial automation and monitoring systems. This product is particularly suited for applications requiring extensive data connectivity and management in various industrial environments.One of the standout features of the LinCon-8000 is its robust connectivity options. It supports multiple communication protocols, including Ethernet, RS-232, and RS-485, allowing seamless integration into existing networks and systems. This flexibility ensures that users can connect the device to a wide range of sensors, devices, and equipment, facilitating real-time data collection and monitoring.

The LinCon-8000 is equipped with a powerful processor and ample memory, enabling efficient handling of large volumes of data. With its real-time data processing capabilities, users can make timely decisions based on the information collected, enhancing operational efficiency and reducing downtime. The device supports various data logging functions, allowing users to store historical data for analysis and reporting purposes.

Moreover, the LinCon-8000 boasts user-friendly configuration tools that simplify the setup process. Users can easily configure the device parameters, manage communications, and set up data logging functions through intuitive software interfaces. This ease of use makes it accessible for both seasoned professionals and individuals new to industrial automation.

In addition to its impressive connectivity and processing capabilities, the LinCon-8000 is designed with reliability in mind. The device is built to withstand harsh industrial environments, featuring robust hardware that can endure temperature fluctuations, humidity, and electromagnetic interference. This durability ensures that the device maintains performance in conditions that could typically hinder less resilient systems.

The LinCon-8000 also prioritizes security with features that protect data integrity and prevent unauthorized access. The device incorporates secure communication protocols, ensuring that data transmission is safeguarded from potential threats.

In summary, the ICP DAS USA LinCon-8000 is a cutting-edge solution for data acquisition and control in industrial settings. Its multiple communication options, powerful processing capabilities, user-friendly configuration, and robust reliability position it as an ideal choice for businesses looking to enhance their operational efficiency and improve monitoring processes in today's fast-paced industrial landscape.