MAINTENANCE SECTION

Assembly of the Impact Mechanism

1.Coat the Hammer (25) with Ingersoll±Rand No. 100 Grease.

2.Position the Hammer inside the Hammer Frame (23) and install the two Hammer Pins (24).

3.Install the Anvil (26) through the Frame and Hammer until it bottoms on the lower part of the Frame.

4.Set the assembled hammer mechanism onto the rotor shaft spline.

5.Place the Hammer Case Gasket (18) over the mechanism against the face of the Motor Housing.

6.Grease the Anvil and top of the Hammer Frame with Ingersoll±Rand No. 100 Grease.

Assembly of the Tool

1.Place the Hammer Case Assembly (16) over the mechanism assembly against the Gasket. Make certain the Hammer Case Label is at the top of the tool.

2.Install the Hammer Case Cap Screws (19) and Lock Washers (20) and using an alternating pattern, tighten the Cap Screws to 20±25 ft±lb (27±34 Nm) torque.

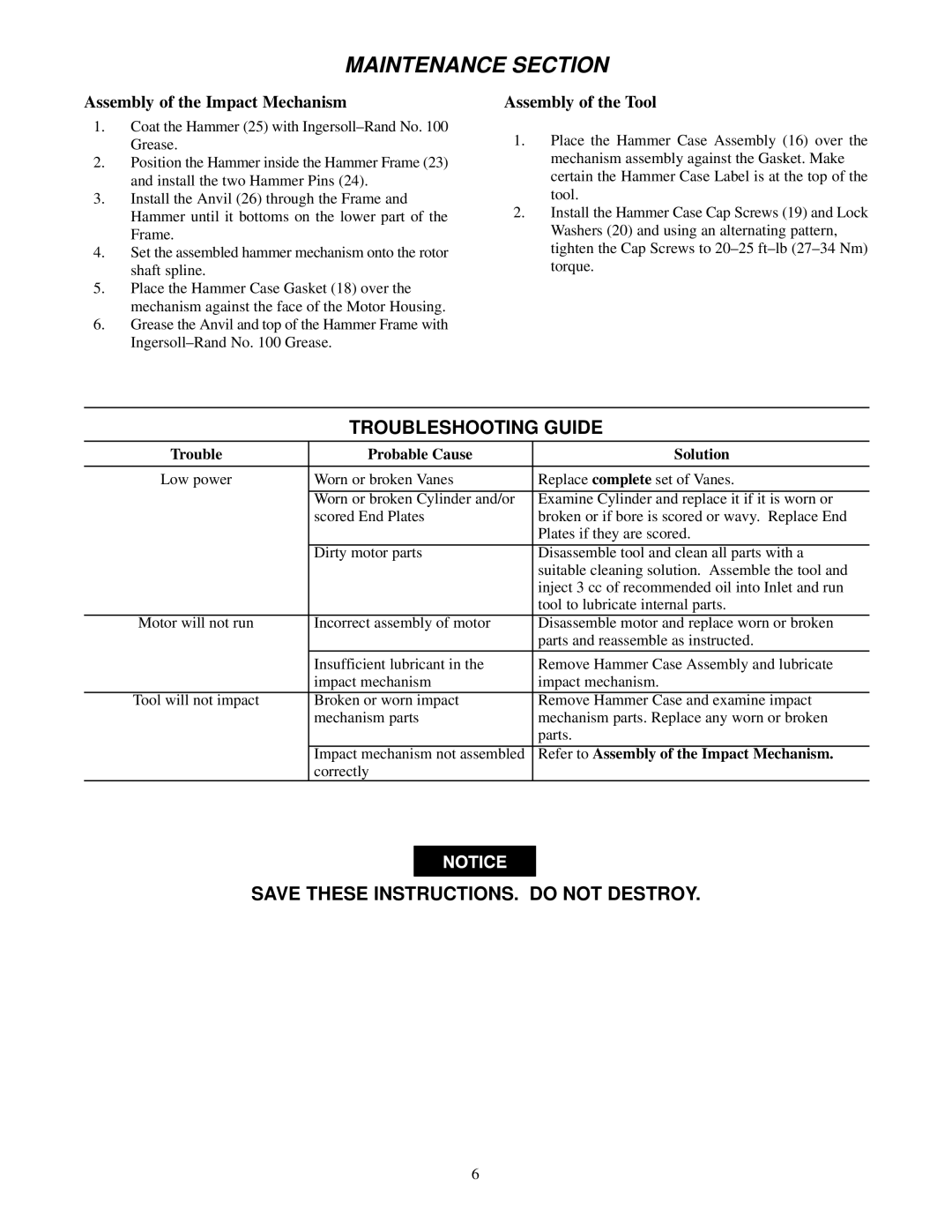

TROUBLESHOOTING GUIDE

Trouble | Probable Cause | Solution |

|

|

|

Low power | Worn or broken Vanes | Replace complete set of Vanes. |

|

|

|

| Worn or broken Cylinder and/or | Examine Cylinder and replace it if it is worn or |

| scored End Plates | broken or if bore is scored or wavy. Replace End |

|

| Plates if they are scored. |

|

|

|

| Dirty motor parts | Disassemble tool and clean all parts with a |

|

| suitable cleaning solution. Assemble the tool and |

|

| inject 3 cc of recommended oil into Inlet and run |

|

| tool to lubricate internal parts. |

|

|

|

Motor will not run | Incorrect assembly of motor | Disassemble motor and replace worn or broken |

|

| parts and reassemble as instructed. |

| Insufficient lubricant in the | Remove Hammer Case Assembly and lubricate |

| impact mechanism | impact mechanism. |

|

|

|

Tool will not impact | Broken or worn impact | Remove Hammer Case and examine impact |

| mechanism parts | mechanism parts. Replace any worn or broken |

|

| parts. |

|

|

|

| Impact mechanism not assembled | Refer to Assembly of the Impact Mechanism. |

| correctly |

|

SAVE THESE INSTRUCTIONS. DO NOT DESTROY.

6