635040 specifications

The Ingersoll-Rand 635040 is a robust and innovative air compressor that has garnered attention in various industries for its high performance and efficiency. This machine stands out for its durability and reliability, making it a preferred choice for both commercial and industrial applications. Its design emphasizes power and longevity, catering to a range of user needs, from construction sites to manufacturing facilities.One of the main features of the Ingersoll-Rand 635040 is its powerful motor, which provides impressive airflow and pressure capabilities. This compressor is engineered to handle demanding tasks, delivering optimal performance in various environments. The unit is designed with advanced noise reduction technology, allowing it to operate quietly while maintaining productivity. This feature is particularly beneficial for users in urban settings or noise-sensitive areas.

The 635040 incorporates several innovative technologies aimed at enhancing its efficiency and operational lifespan. Its integrated air treatment system ensures that the air produced is free from contamination, providing clean, dry air that is essential for many applications. This system includes filters and dryers that work together seamlessly, reducing the risk of equipment damage and ensuring reliable performance.

Additionally, this air compressor features a user-friendly control panel that simplifies operation. The intuitive controls allow users to monitor performance metrics and adjust settings with ease, enhancing overall efficiency. The unit is designed with portability in mind, featuring a compact construction and durable wheels, making it easy to transport across job sites.

In terms of characteristics, the Ingersoll-Rand 635040 boasts a rugged build that can withstand tough conditions. Its corrosion-resistant frame ensures longevity, even when exposed to harsh environments. The compressor is also equipped with safety features, such as automatic shut-off mechanisms that prevent overheating and protect the unit's components.

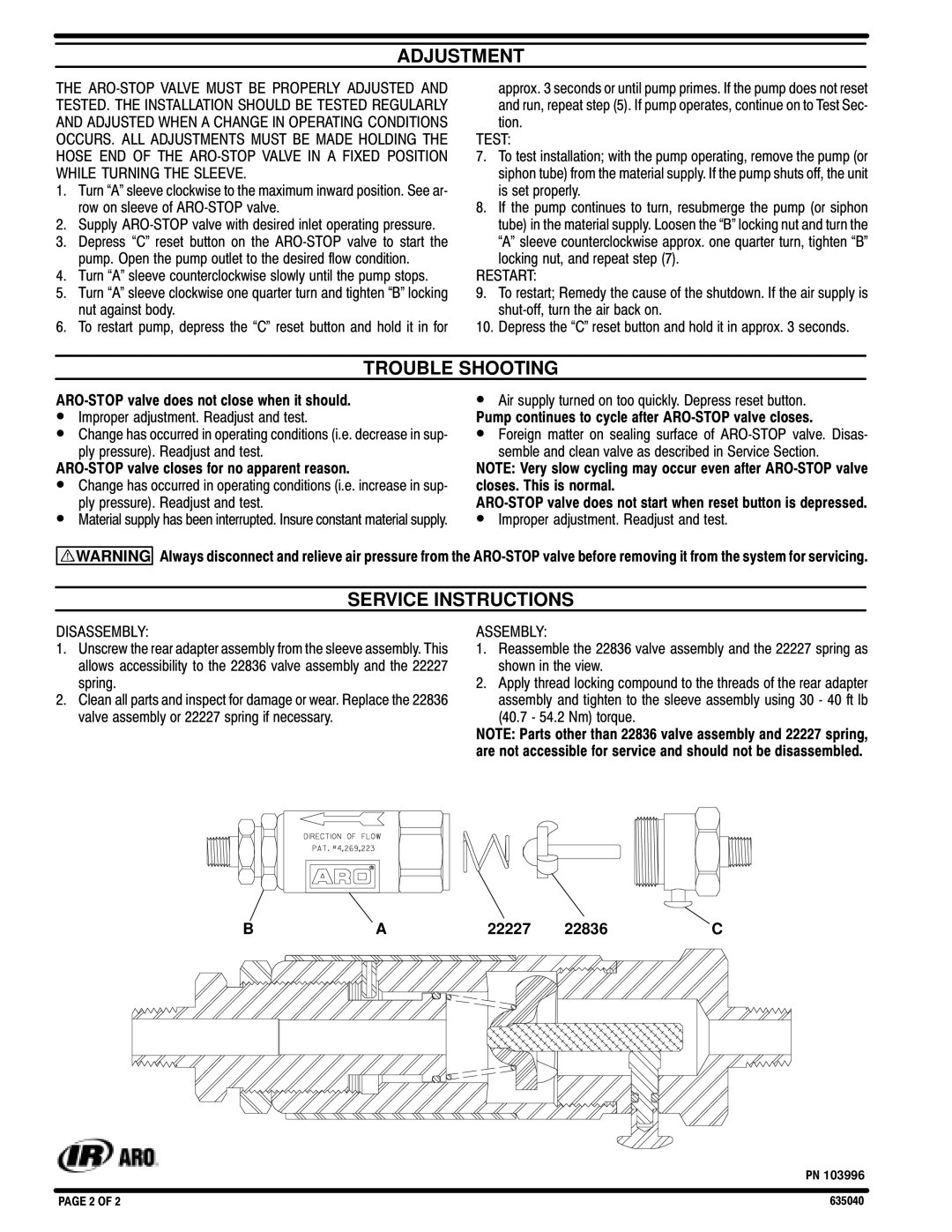

Maintenance is straightforward, with accessible components that make routine checks and servicing hassle-free. This focus on maintenance further contributes to the compressor’s extended service life and reliability.

In conclusion, the Ingersoll-Rand 635040 is a powerful and efficient air compressor that delivers consistent performance across a variety of applications. Its blend of advanced features, cutting-edge technologies, and robust construction make it an excellent choice for those in need of a dependable air supply solution. Whether for industrial use or construction needs, this air compressor stands as a testament to Ingersoll-Rand's commitment to innovation and quality.