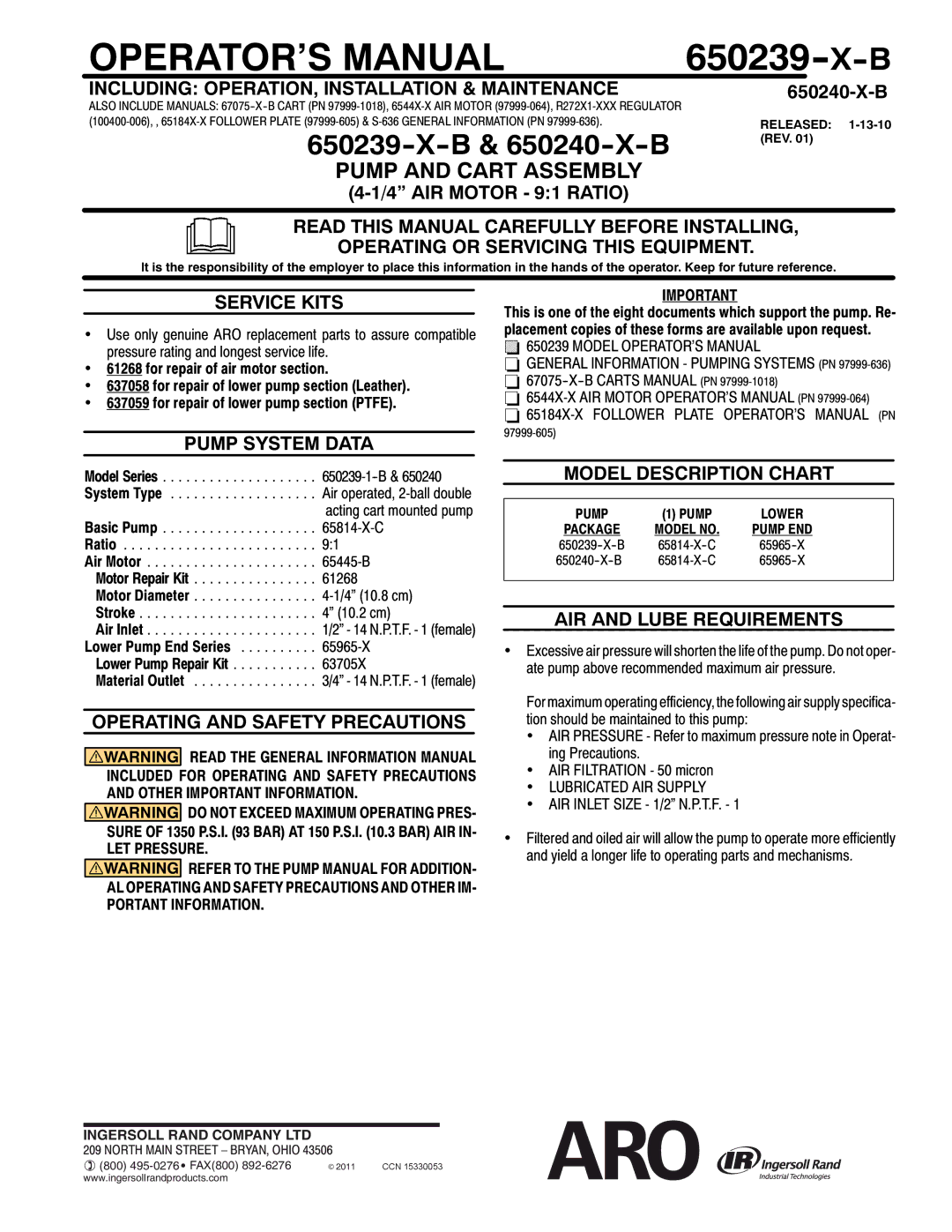

650240-X-B, 650239-X-B specifications

Ingersoll-Rand has long been recognized as a leader in providing innovative solutions for compressed air and fluid management applications. Two of the standout products from their extensive portfolio are the Ingersoll-Rand 650240-X-B and 650239-X-B, both of which showcase cutting-edge technology and remarkable features that cater to various industrial needs.The Ingersoll-Rand 650240-X-B is designed for those who require high efficiency and performance in their operations. This model incorporates advanced rotary screw technology, which optimizes airflow and increases energy savings. The 650240-X-B features a robust design that ensures durability and longevity, making it an ideal choice for demanding environments. Its user-friendly interface allows for easy monitoring and control, while the built-in sound enclosure minimizes noise levels, making it suitable for locations where noise control is essential.

On the other hand, the Ingersoll-Rand 650239-X-B is engineered with slightly different applications in mind but maintains the same high quality and reliability. This model also utilizes rotary screw technology, ensuring efficient operation and reduced energy costs. Its compact design makes it an excellent choice for facilities with space constraints. The 650239-X-B comes equipped with a state-of-the-art control system that provides real-time operational data, allowing users to optimize their compressed air systems for greater efficiency.

Both models are built with energy-saving features, including variable speed drive options, which adjust the compressor's speed according to the demand for compressed air, resulting in significant power savings. Furthermore, both units offer straightforward maintenance access, reducing downtime and ensuring that regular servicing can be carried out quickly and effectively.

Ingersoll-Rand has also integrated advanced filtering systems in the 650240-X-B and 650239-X-B models to ensure clean, dry air is supplied, protecting downstream equipment and extending the lifespan of pneumatic tools. These features highlight the company’s commitment to not only performance but also environmental responsibility.

In summary, the Ingersoll-Rand 650240-X-B and 650239-X-B are exceptional products that embody the brand’s legacy of reliability, efficiency, and innovation. With their cutting-edge technologies and features, these models are a smart investment for any industrial facility seeking to enhance their operational efficiency while minimizing costs and environmental impact.