SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

ELECTRICAL INSTALLATION INSTRUCTIONS

SHOCK ABSORBER: It is also recommended that a shock absorber (not supplied with the

CONNECTING THE DRAIN LINE: The

PLUMBING CHECK: Slowly turn on the water supply to the machine after the incoming fill line and the drain line have been installed. Check for any leaks and repair as required. All leaks must be repaired prior to placing the machine in operation.

ELECTRICAL POWER CONNECTION: Electrical and grounding connections must comply with the applicable portions of the National Electrical Code ANSI/NFPA 70 (latest edition) and/or other electrical codes.

Disconnect electrical power supply and place a tag at the disconnect switch to indicate that you are working on the circuit.

The dishmachine data plate is located on the front of the machine. Refer to the data plate for machine operating requirements, machine voltage, total amper- age load and serial number.

To install the incoming power lines, remove the kick panel. This will require tak- ing a phillips head screwdriver and removing the two screws at the bottom of the kick panel; open the door slightly while carefully lifting the kick panel up and out of the way. Install 3/4” conduit into the

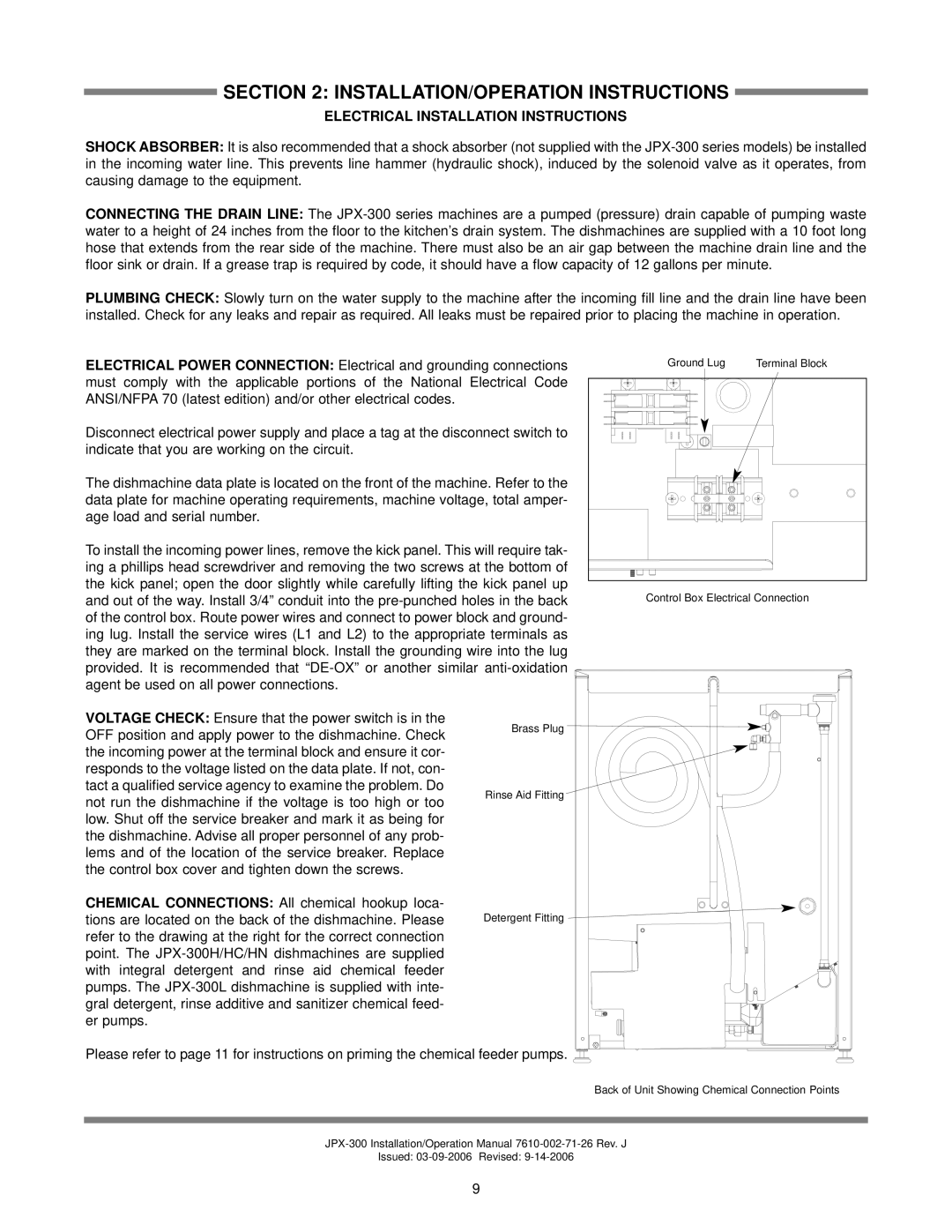

Ground Lug | Terminal Block |

Control Box Electrical Connection

VOLTAGE CHECK: Ensure that the power switch is in the OFF position and apply power to the dishmachine. Check the incoming power at the terminal block and ensure it cor- responds to the voltage listed on the data plate. If not, con- tact a qualified service agency to examine the problem. Do not run the dishmachine if the voltage is too high or too low. Shut off the service breaker and mark it as being for the dishmachine. Advise all proper personnel of any prob- lems and of the location of the service breaker. Replace the control box cover and tighten down the screws.

Brass Plug ![]()

Rinse Aid Fitting

CHEMICAL CONNECTIONS: All chemical hookup loca- tions are located on the back of the dishmachine. Please refer to the drawing at the right for the correct connection point. The

Detergent Fitting ![]()

Please refer to page 11 for instructions on priming the chemical feeder pumps.

Back of Unit Showing Chemical Connection Points

Issued:

9