JWP-15HH, JWP-15DX specifications

Jet Tools has established itself as a prominent name in the woodworking industry, producing high-quality machinery designed for both professional woodworkers and hobbyists. Two of their standout products are the JWP-15DX and the JWP-15HH, both of which are exceptional planers known for their durability and performance.The Jet JWP-15DX is a powerful 15-inch planer that efficiently handles a wide range of materials. One of its main features is the three-knife cutter head, which ensures a smooth finish and improved chip removal. This design allows for more cutting action with each pass, reducing the workload and time required for projects. Additionally, the JWP-15DX boasts a robust 3-horsepower motor, providing ample power for heavy-duty tasks while maintaining a consistent feed rate that enhances precision.

Another significant characteristic of the JWP-15DX is its adjustable depth control system, allowing woodworkers to make precise adjustments easily. The integrated digital readout provides clear visibility of the settings, ensuring users can effortlessly achieve the desired thickness. Furthermore, this planer features a table extension that provides support for larger workpieces, enhancing stability during operation.

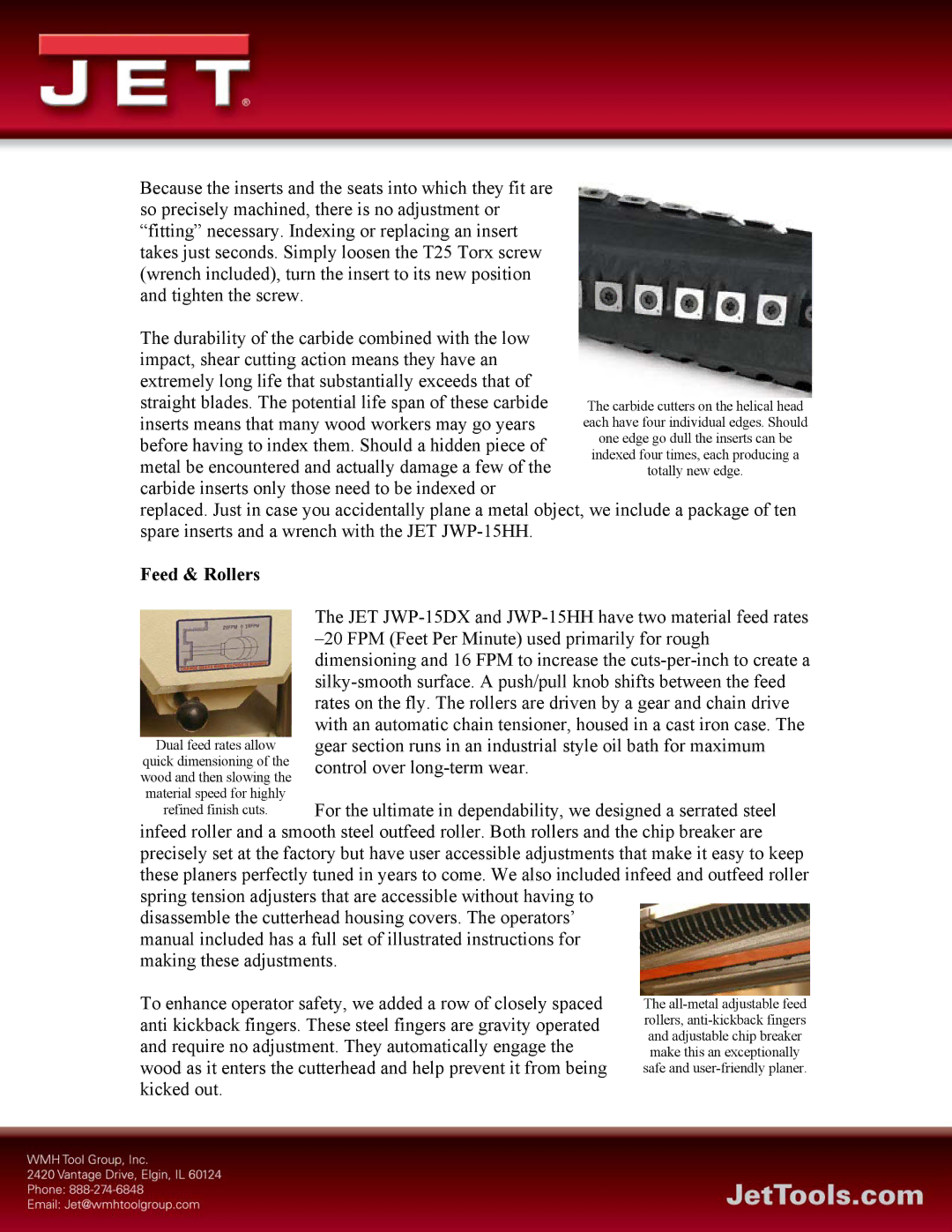

On the other hand, the Jet JWP-15HH comes equipped with a helical cutter head, featuring 40 insert knives that deliver a superior finish and significantly reduce noise levels during operation. This technology allows for a smoother cut and less friction, resulting in extended tool life and reduced maintenance. The JWP-15HH also has a 3-horsepower motor, mirroring the JWP-15DX in power but taking performance a step further with its innovative cutter head design.

Both planers incorporate Jet's signature build quality, intended for long-lasting reliability in demanding environments. The adjustable infeed and outfeed tables enhance user convenience and ensure optimal performance when working with larger materials. Moreover, their dust collection ports allow for efficient debris removal, keeping the workspace cleaner and safer.

Overall, the Jet JWP-15DX and JWP-15HH stand out in their class with advanced features, innovative technologies, and excellent build quality, making them ideal choices for woodworkers looking to achieve professional results in their projects. Whether opting for the efficiency of a three-knife cutter head or the quiet performance of a helical design, both models deliver exceptional reliability and performance.