TURN-ON LEAD

The A1800 uses a conventional +12V remote turn-on lead, typically controlled by the source unit's remote turn-on output. The amplifier will turn on when +12V is present at its “Remote” input and turn off when +12V is switched off. If a source unit does not have a dedicated remote turn-on output, the amplifier’s turn-on lead can be connected to +12V via a switch that derives power from an ignition-switched circuit.

The A1800’s “Remote” turn-on connector is designed to accept 18 AWG – 12 AWG wire. To connect the remote turn-on wire to the amplifier, first back out the set screw on the top of the terminal block, using the supplied 2.5 mm hex wrench. Strip 1/2 inch (12mm) of wire and insert the bare wire into the terminal block, seating it firmly so that no bare wire is exposed. While holding the wire in the terminal, tighten the set screw firmly, taking care not to strip the head of the screw and making sure that the wire is firmly gripped by the set screw.

INPUT SECTION

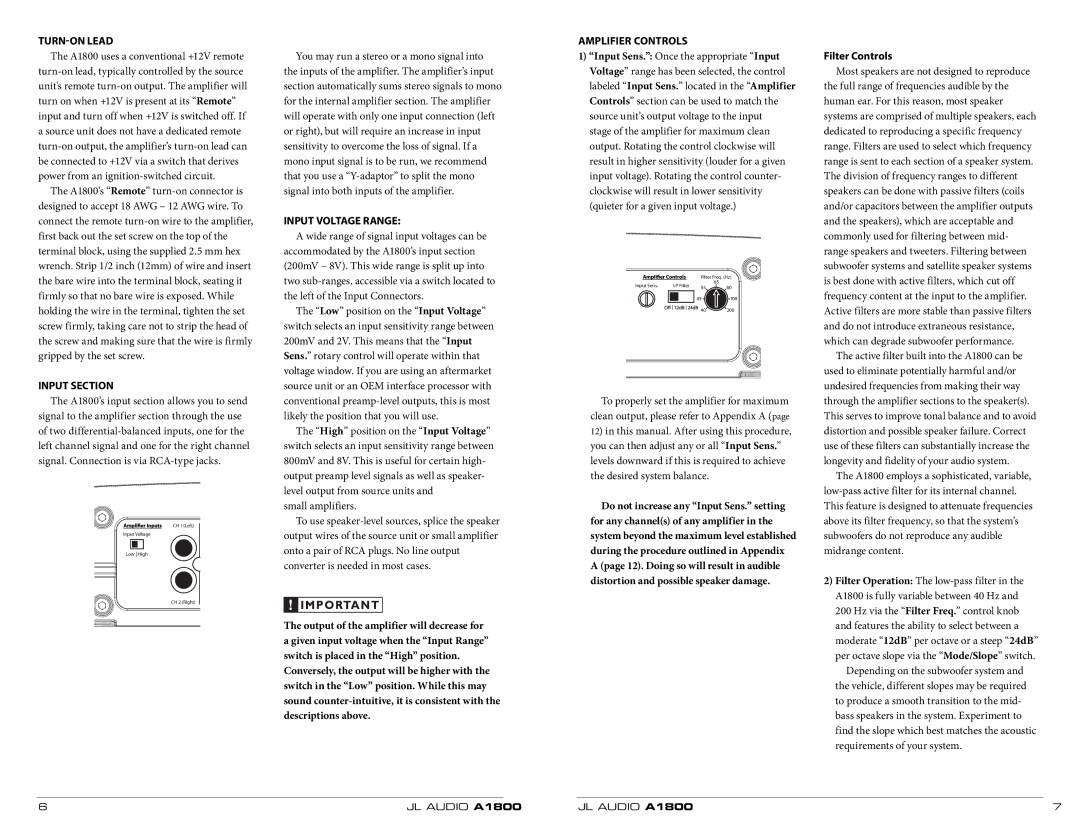

The A1800’s input section allows you to send signal to the amplifier section through the use of two differential-balanced inputs, one for the left channel signal and one for the right channel signal. Connection is via RCA-type jacks.

CH 1 (Left)

Input Voltage

Low High

CH 2 (Right)

You may run a stereo or a mono signal into the inputs of the amplifier. The amplifier’s input section automatically sums stereo signals to mono for the internal amplifier section. The amplifier will operate with only one input connection (left or right), but will require an increase in input sensitivity to overcome the loss of signal. If a mono input signal is to be run, we recommend that you use a “Y-adaptor” to split the mono signal into both inputs of the amplifier.

INPUT VOLTAGE RANGE:

A wide range of signal input voltages can be accommodated by the A1800’s input section (200mV – 8V). This wide range is split up into two sub-ranges, accessible via a switch located to the left of the Input Connectors.

The “Low” position on the “Input Voltage” switch selects an input sensitivity range between 200mV and 2V. This means that the “Input Sens.” rotary control will operate within that voltage window. If you are using an aftermarket source unit or an OEM interface processor with conventional preamp-level outputs, this is most likely the position that you will use.

The “High” position on the “Input Voltage” switch selects an input sensitivity range between 800mV and 8V. This is useful for certain high- output preamp level signals as well as speaker- level output from source units and

small amplifiers.

To use speaker-level sources, splice the speaker output wires of the source unit or small amplifier onto a pair of RCA plugs. No line output converter is needed in most cases.

The output of the amplifier will decrease for a given input voltage when the “Input Range” switch is placed in the “High” position.

Conversely, the output will be higher with the switch in the “Low” position. While this may sound counter-intuitive, it is consistent with the descriptions above.

AMPLIFIER CONTROLS

1)“Input Sens.”: Once the appropriate “Input Voltage” range has been selected, the control labeled “Input Sens.” located in the “Amplifier Controls” section can be used to match the source unit’s output voltage to the input stage of the amplifier for maximum clean output. Rotating the control clockwise will result in higher sensitivity (louder for a given input voltage). Rotating the control counter- clockwise will result in lower sensitivity (quieter for a given input voltage.)

| | | Filter Freq. (Hz) |

| Input Sens. | LP Filter | | 65 |

| 55 | 80 |

| | |

| | | 45 | 100 |

| | | 40 | 200 |

To properly set the amplifier for maximum clean output, please refer to Appendix A (page 12) in this manual. After using this procedure, you can then adjust any or all “Input Sens.” levels downward if this is required to achieve the desired system balance.

Do not increase any “Input Sens.” setting for any channel(s) of any amplifier in the system beyond the maximum level established during the procedure outlined in Appendix A (page 12). Doing so will result in audible distortion and possible speaker damage.

Filter Controls

Most speakers are not designed to reproduce the full range of frequencies audible by the human ear. For this reason, most speaker systems are comprised of multiple speakers, each dedicated to reproducing a specific frequency range. Filters are used to select which frequency range is sent to each section of a speaker system. The division of frequency ranges to different speakers can be done with passive filters (coils and/or capacitors between the amplifier outputs and the speakers), which are acceptable and commonly used for filtering between mid- range speakers and tweeters. Filtering between subwoofer systems and satellite speaker systems is best done with active filters, which cut off frequency content at the input to the amplifier. Active filters are more stable than passive filters and do not introduce extraneous resistance, which can degrade subwoofer performance.

The active filter built into the A1800 can be used to eliminate potentially harmful and/or undesired frequencies from making their way through the amplifier sections to the speaker(s). This serves to improve tonal balance and to avoid distortion and possible speaker failure. Correct use of these filters can substantially increase the longevity and fidelity of your audio system.

The A1800 employs a sophisticated, variable, low-pass active filter for its internal channel. This feature is designed to attenuate frequencies above its filter frequency, so that the system’s subwoofers do not reproduce any audible midrange content.

2)Filter Operation: The low-pass filter in the A1800 is fully variable between 40 Hz and

200 Hz via the “Filter Freq.” control knob and features the ability to select between a moderate “12dB” per octave or a steep “24dB” per octave slope via the “Mode/Slope” switch.

Depending on the subwoofer system and the vehicle, different slopes may be required to produce a smooth transition to the mid- bass speakers in the system. Experiment to find the slope which best matches the acoustic requirements of your system.