CS 2255 specifications

The Jonsered CS 2255 is a versatile and powerful chainsaw designed for both homeowners and professional users who require reliability and efficiency in their cutting tasks. This model is particularly well-regarded for its robust performance and user-friendly features, making it a popular choice among outdoor enthusiasts and forestry workers alike.One of the most commendable features of the Jonsered CS 2255 is its highly efficient engine. Equipped with a 55.5cc two-stroke engine, it delivers exceptional power output while ensuring lower emissions and reduced fuel consumption. The engine is designed with advanced technology that minimizes the environmental impact without compromising on performance. This balance of power and efficiency makes the CS 2255 ideal for a variety of cutting applications, from felling trees to trimming branches.

The CS 2255 is also notable for its ergonomic design. The chainsaw incorporates a well-thought-out handle system that provides optimal comfort during extended use. The comfortable grips reduce fatigue and enhance control, allowing users to work longer without discomfort. Furthermore, the low vibration technology integrated into the design significantly decreases vibration levels, leading to a smoother operation and improved handling.

Another distinguishing feature of the Jonsered CS 2255 is its quick-start system, which simplifies the starting procedure. Users appreciate this feature, especially in colder weather conditions or when the chainsaw hasn't been used for a while. The easy start mechanism ensures reliability and efficiency, enabling the user to get to work without unnecessary delays.

Safety is a primary concern in chainsaw operation, and the CS 2255 is equipped with various safety mechanisms to mitigate risks. The chainsaw comes with an effective chain brake and a throttle lock that helps prevent accidental starts. These features provide peace of mind for users who prioritize safety while working in demanding environments.

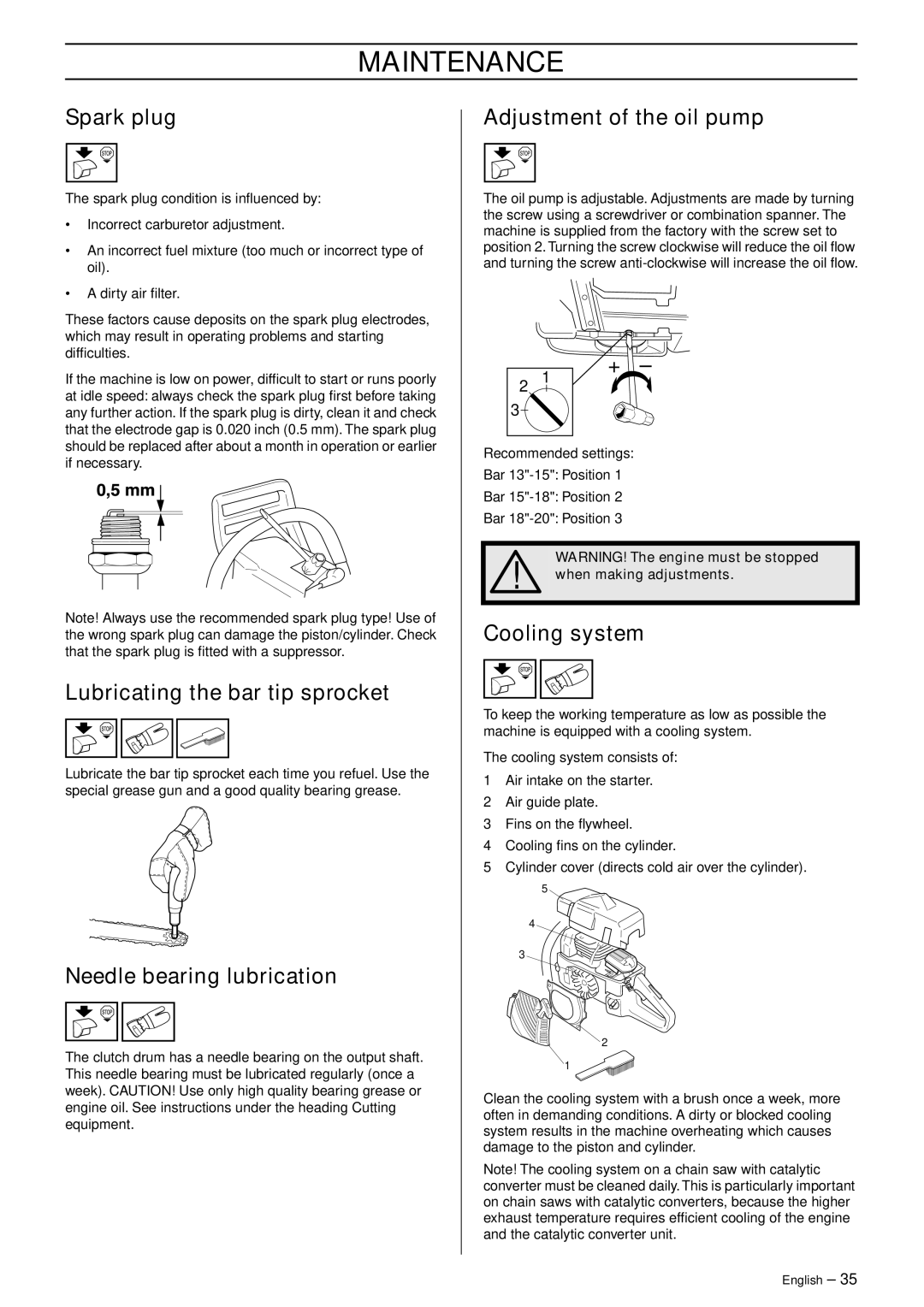

In addition to its impressive features, the Jonsered CS 2255 supports ease of maintenance. The tool-less chain tensioning system enables quick adjustments, while the air injection system reduces filter cleaning intervals. These qualities enhance the overall user experience and ensure that the chainsaw remains in top condition with minimal effort.

Whether you are a seasoned professional or a casual user, the Jonsered CS 2255 offers a combination of power, efficiency, and user-friendly features that make it an excellent choice for all your cutting needs.