This tool is intended for cutting unhardened ferrous metal and

•Do not cut stacked materials. Cut one piece at a time.

•Do not cut hardened steel.

•Cut materials with the wider edge of the shoe over the clamped side of the material.

•Do not touch the blade, workpiece, chips, or chip container with bare hands immediately after cutting; they may be hot and could burn skin.

CUTTING THIN OR CORRUGATED MATERIALS

Cut thin and corrugated materials at least 1" from the edge of the workpiece to avoid injury or damage to the tool caused by thin strips of metal being pulled into the upper guard.

CUTTING LARGE SHEETS

Large sheets sag or bend if they are not correctly supported. If you attempt to cut without leveling and properly supporting the workpiece, the blade will tend to bind, causing KICKBACK.

Support large sheets. Be sure to set the depth of the cut so that you can only cut through the workpiece, not through the supports.

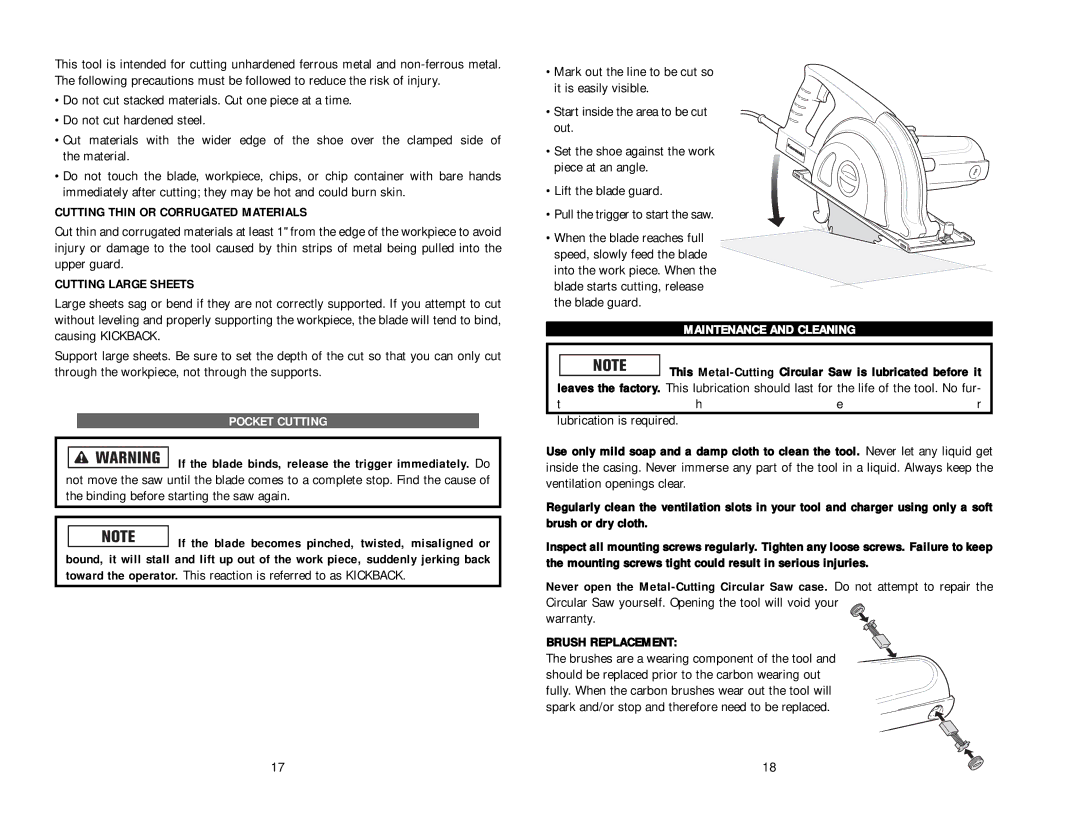

POCKET CUTTING

![]() If the blade binds, release the trigger immediately. Do not move the saw until the blade comes to a complete stop. Find the cause of the binding before starting the saw again.

If the blade binds, release the trigger immediately. Do not move the saw until the blade comes to a complete stop. Find the cause of the binding before starting the saw again.

![]() If the blade becomes pinched, twisted, misaligned or bound, it will stall and lift up out of the work piece, suddenly jerking back toward the operator. This reaction is referred to as KICKBACK.

If the blade becomes pinched, twisted, misaligned or bound, it will stall and lift up out of the work piece, suddenly jerking back toward the operator. This reaction is referred to as KICKBACK.

• Mark out the line to be cut so it is easily visible.

• Start inside the area to be cut out.

• Set the shoe against the work piece at an angle.

• Lift the blade guard.

• Pull the trigger to start the saw.

• When the blade reaches full speed, slowly feed the blade into the work piece. When the blade starts cutting, release the blade guard.

MAINTENANCE AND CLEANING

![]() This

This

ther

lubrication is required.

Use only mild soap and a damp cloth to clean the tool. Never let any liquid get inside the casing. Never immerse any part of the tool in a liquid. Always keep the ventilation openings clear.

Regularly clean the ventilation slots in your tool and charger using only a soft brush or dry cloth.

Inspect all mounting screws regularly. Tighten any loose screws. Failure to keep the mounting screws tight could result in serious injuries.

Never open the

warranty.

BRUSH REPLACEMENT:

The brushes are a wearing component of the tool and should be replaced prior to the carbon wearing out fully. When the carbon brushes wear out the tool will spark and/or stop and therefore need to be replaced.

17 | 18 |