ASSEMBLE ROTARY TOOL STAND

FOR MODEL 840169:

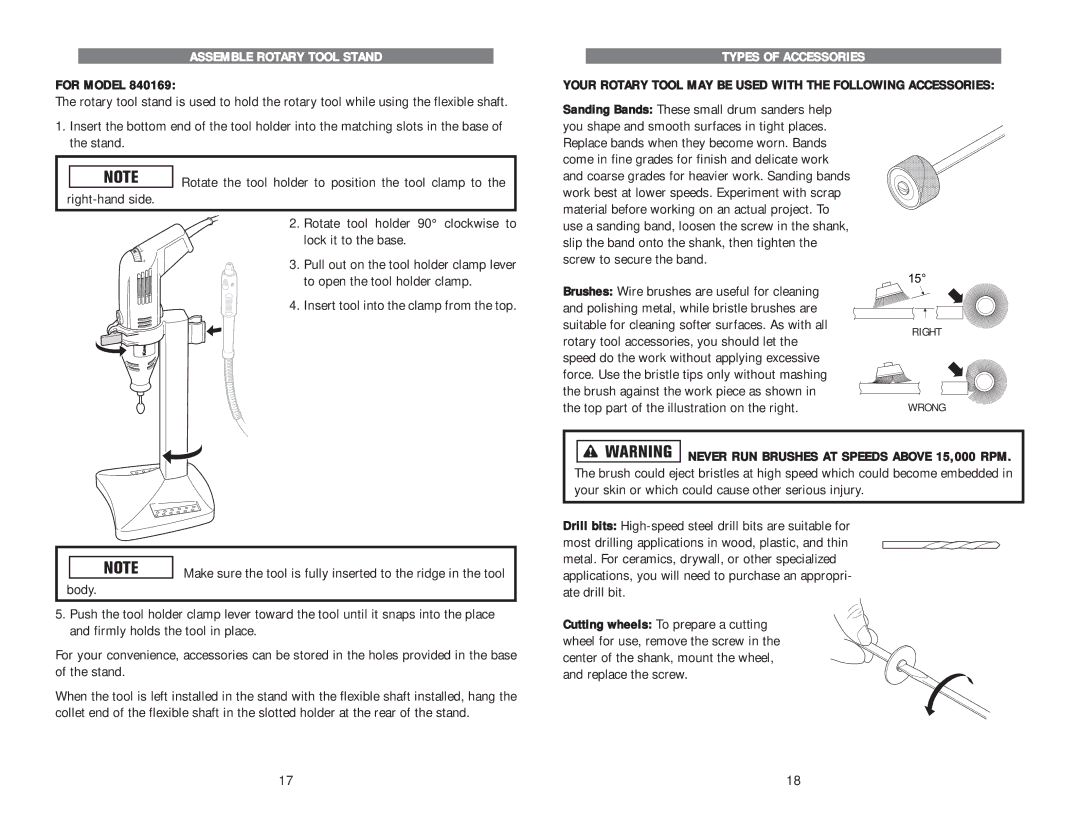

The rotary tool stand is used to hold the rotary tool while using the flexible shaft.

1.Insert the bottom end of the tool holder into the matching slots in the base of the stand.

![]()

![]()

![]()

![]() Rotate the tool holder to position the tool clamp to the

Rotate the tool holder to position the tool clamp to the

2. Rotate tool holder 90° clockwise to lock it to the base.

3. Pull out on the tool holder clamp lever to open the tool holder clamp.

4. Insert tool into the clamp from the top.

![]()

![]()

![]()

![]() Make sure the tool is fully inserted to the ridge in the tool body.

Make sure the tool is fully inserted to the ridge in the tool body.

5.Push the tool holder clamp lever toward the tool until it snaps into the place and firmly holds the tool in place.

For your convenience, accessories can be stored in the holes provided in the base of the stand.

When the tool is left installed in the stand with the flexible shaft installed, hang the collet end of the flexible shaft in the slotted holder at the rear of the stand.

TYPES OF ACCESSORIES

YOUR ROTARY TOOL MAY BE USED WITH THE FOLLOWING ACCESSORIES:

Sanding Bands: These small drum sanders help you shape and smooth surfaces in tight places. Replace bands when they become worn. Bands come in fine grades for finish and delicate work and coarse grades for heavier work. Sanding bands work best at lower speeds. Experiment with scrap material before working on an actual project. To use a sanding band, loosen the screw in the shank, slip the band onto the shank, then tighten the screw to secure the band.

15°

Brushes: Wire brushes are useful for cleaning |

| |

and polishing metal, while bristle brushes are |

| |

suitable for cleaning softer surfaces. As with all | RIGHT | |

rotary tool accessories, you should let the | ||

| ||

speed do the work without applying excessive |

| |

force. Use the bristle tips only without mashing |

| |

the brush against the work piece as shown in |

| |

the top part of the illustration on the right. | WRONG |

NEVER RUN BRUSHES AT SPEEDS ABOVE 15,000 RPM.

The brush could eject bristles at high speed which could become embedded in your skin or which could cause other serious injury.

Drill bits:

Cutting wheels: To prepare a cutting wheel for use, remove the screw in the center of the shank, mount the wheel, and replace the screw.

17 | 18 |