I N S T A L L A T I O N I N S T R U C T I O N S

| Part No. 055523 |

|

|

|

|

www.keatingofchicago.com |

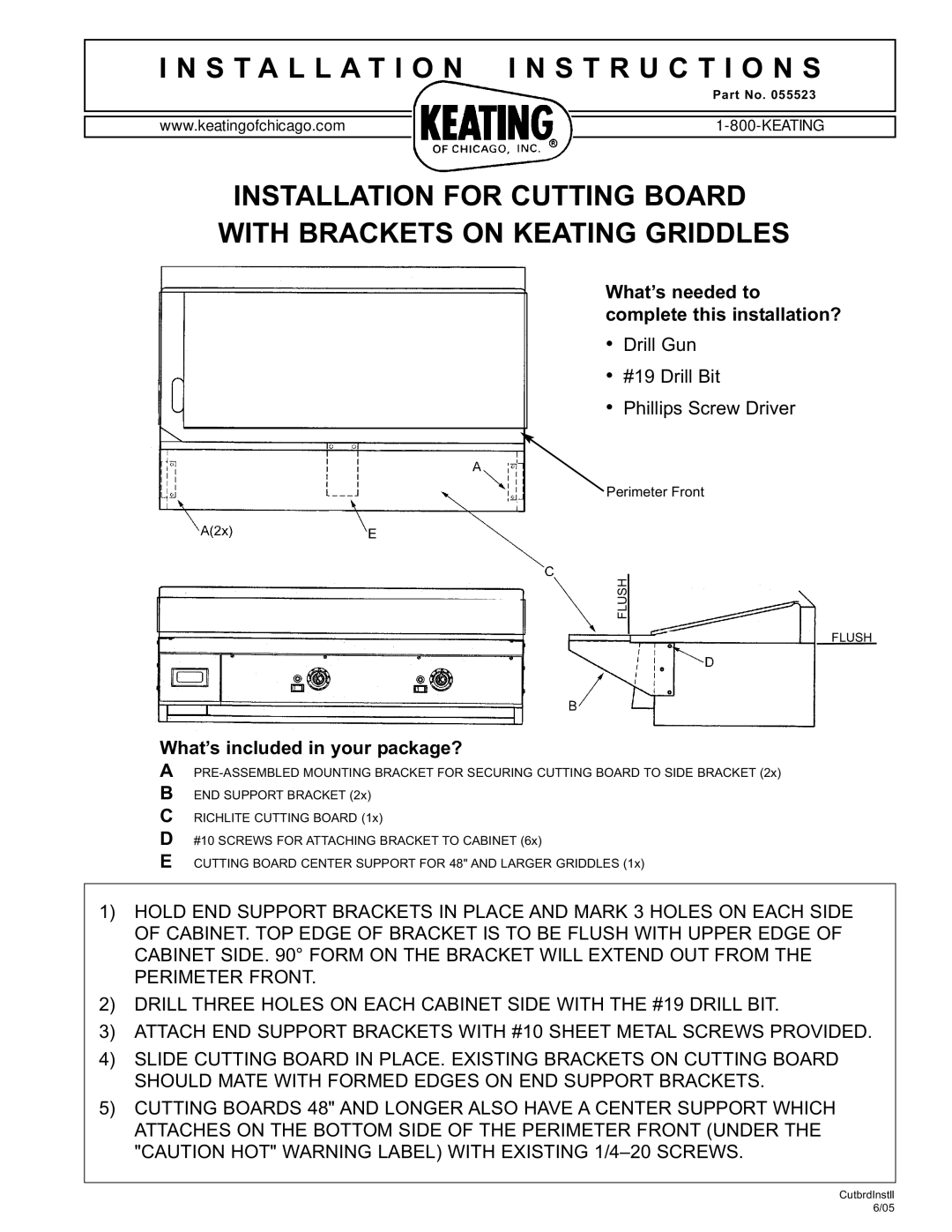

INSTALLATION FOR CUTTING BOARD

WITH BRACKETS ON KEATING GRIDDLES

What’s needed to complete this installation?

• Drill Gun

• #19 Drill Bit

• Phillips Screw Driver

Perimeter Front

FLUSH

FLUSH

What’s included in your package?

A

BEND SUPPORT BRACKET (2x)

CRICHLITE CUTTING BOARD (1x)

D#10 SCREWS FOR ATTACHING BRACKET TO CABINET (6x)

ECUTTING BOARD CENTER SUPPORT FOR 48" AND LARGER GRIDDLES (1x)

1)HOLD END SUPPORT BRACKETS IN PLACE AND MARK 3 HOLES ON EACH SIDE OF CABINET. TOP EDGE OF BRACKET IS TO BE FLUSH WITH UPPER EDGE OF CABINET SIDE. 90° FORM ON THE BRACKET WILL EXTEND OUT FROM THE PERIMETER FRONT.

2)DRILL THREE HOLES ON EACH CABINET SIDE WITH THE #19 DRILL BIT.

3)ATTACH END SUPPORT BRACKETS WITH #10 SHEET METAL SCREWS PROVIDED.

4)SLIDE CUTTING BOARD IN PLACE. EXISTING BRACKETS ON CUTTING BOARD SHOULD MATE WITH FORMED EDGES ON END SUPPORT BRACKETS.

5)CUTTING BOARDS 48" AND LONGER ALSO HAVE A CENTER SUPPORT WHICH ATTACHES ON THE BOTTOM SIDE OF THE PERIMETER FRONT (UNDER THE "CAUTION HOT" WARNING LABEL) WITH EXISTING

CutbrdInstll 6/05