20 BB GAS

20 BB GAS

INSTANT RECOVERY® FRYER

DESCRIPTION

The Keating Instant Recovery® 20 BB Fryer consists of a frying vessel 20" sq., having a splash deck and a splash back installed in a cabinet equipped with gas burners and an automatic temperature control mechanism, all arranged and designed for the proper frying of food.

SPECIFICATIONS

Frying Vessel: shall be constructed from 18 gauge stainless steel, shall have a shortening capacity of 100 pounds, shall be equipped with four 18 gauge horizontal heat transfer tubes spaced above the bottom of the vessel so that the bottom is unheated and the food particles collecting in this bottom zone are unheated and therefore do not carbonize. The frying vessel shall be polished to inhibit carbon

Splashdeck shall slope toward the shortening containing vessel.

The splash deck shall be made of 16 gauge 304 stainless steel.

Splashback shall be made of 18 gauge 304 stainless steel, shall completely cover the sides of the flue.

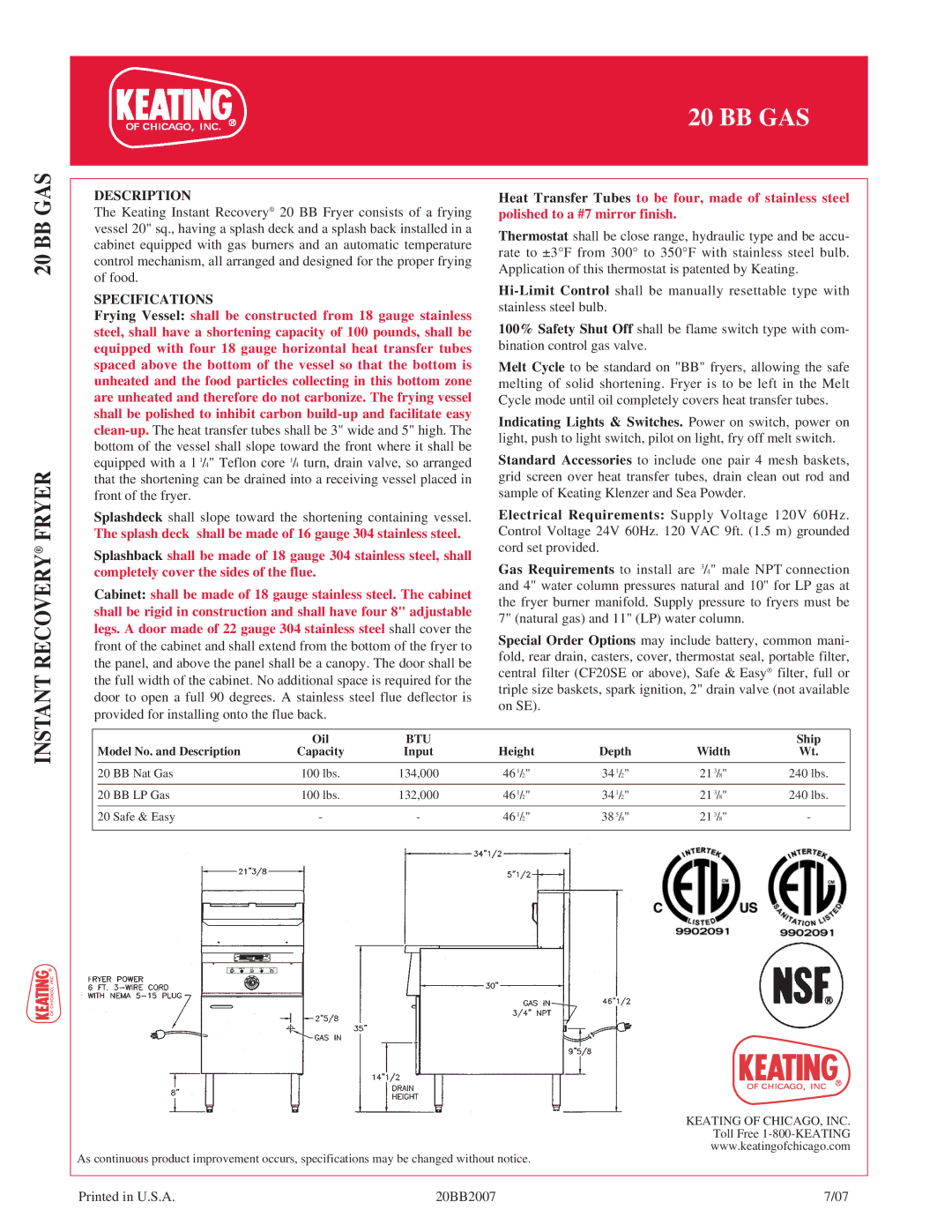

Cabinet: shall be made of 18 gauge stainless steel. The cabinet shall be rigid in construction and shall have four 8" adjustable legs. A door made of 22 gauge 304 stainless steel shall cover the front of the cabinet and shall extend from the bottom of the fryer to the panel, and above the panel shall be a canopy. The door shall be the full width of the cabinet. No additional space is required for the door to open a full 90 degrees. A stainless steel flue deflector is provided for installing onto the flue back.

Heat Transfer Tubes to be four, made of stainless steel polished to a #7 mirror finish.

Thermostat shall be close range, hydraulic type and be accu- rate to ±3°F from 300° to 350°F with stainless steel bulb. Application of this thermostat is patented by Keating.

100% Safety Shut Off shall be flame switch type with com- bination control gas valve.

Melt Cycle to be standard on "BB" fryers, allowing the safe melting of solid shortening. Fryer is to be left in the Melt Cycle mode until oil completely covers heat transfer tubes.

Indicating Lights & Switches. Power on switch, power on light, push to light switch, pilot on light, fry off melt switch.

Standard Accessories to include one pair 4 mesh baskets, grid screen over heat transfer tubes, drain clean out rod and sample of Keating Klenzer and Sea Powder.

Electrical Requirements: Supply Voltage 120V 60Hz. Control Voltage 24V 60Hz. 120 VAC 9ft. (1.5 m) grounded cord set provided.

Gas Requirements to install are 3/4" male NPT connection and 4" water column pressures natural and 10" for LP gas at the fryer burner manifold. Supply pressure to fryers must be 7" (natural gas) and 11" (LP) water column.

Special Order Options may include battery, common mani- fold, rear drain, casters, cover, thermostat seal, portable filter, central filter (CF20SE or above), Safe & Easy® filter, full or triple size baskets, spark ignition, 2" drain valve (not available on SE).

|

| Oil | BTU |

|

|

| Ship | |

Model No. and Description | Capacity | Input | Height | Depth | Width | Wt. | ||

|

|

|

|

|

|

|

|

|

20 | BB Nat Gas | 100 lbs. | 134,000 | 46 1/2" | 34 1/2" | 21 3/8" | 240 lbs. | |

|

|

|

|

|

|

|

|

|

20 | BB LP Gas | 100 lbs. | 132,000 | 46 1/2" | 34 1/2" | 21 3/8" | 240 lbs. | |

|

|

|

|

|

|

|

|

|

20 | Safe & Easy | - | - | 46 1/2" | 38 5/8" | 21 3/8" | - |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

KEATING OF CHICAGO, INC. Toll Free

As continuous product improvement occurs, specifications may be changed without notice.

Printed in U.S.A. | 20BB2007 | 7/07 |