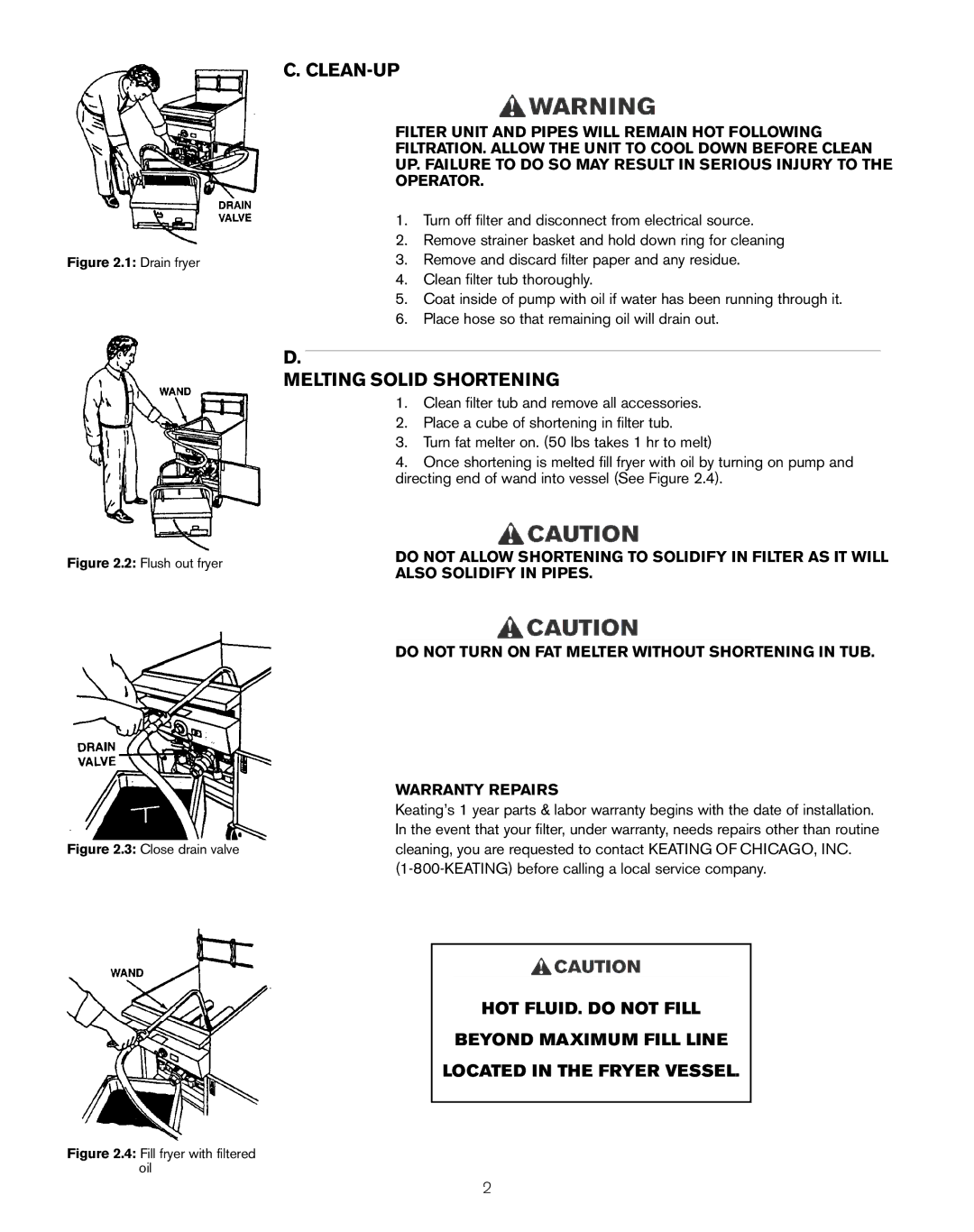

Figure 2.1: Drain fryer

Figure 2.2: Flush out fryer

Figure 2.3: Close drain valve

C. CLEAN-UP

FILTER UNIT AND PIPES WILL REMAIN HOT FOLLOWING FILTRATION. ALLOW THE UNIT TO COOL DOWN BEFORE CLEAN UP. FAILURE TO DO SO MAY RESULT IN SERIOUS INJURY TO THE OPERATOR.

1.Turn off filter and disconnect from electrical source.

2.Remove strainer basket and hold down ring for cleaning

3.Remove and discard filter paper and any residue.

4.Clean filter tub thoroughly.

5.Coat inside of pump with oil if water has been running through it.

6.Place hose so that remaining oil will drain out.

D.

MELTING SOLID SHORTENING

1.Clean filter tub and remove all accessories.

2.Place a cube of shortening in filter tub.

3.Turn fat melter on. (50 lbs takes 1 hr to melt)

4.Once shortening is melted fill fryer with oil by turning on pump and directing end of wand into vessel (See Figure 2.4).

DO NOT ALLOW SHORTENING TO SOLIDIFY IN FILTER AS IT WILL ALSO SOLIDIFY IN PIPES.

DO NOT TURN ON FAT MELTER WITHOUT SHORTENING IN TUB.

WARRANTY REPAIRS

Keating’s 1 year parts & labor warranty begins with the date of installation. In the event that your filter, under warranty, needs repairs other than routine cleaning, you are requested to contact KEATING OF CHICAGO, INC.

HOT FLUID. DO NOT FILL

BEYOND MAXIMUM FILL LINE

LOCATED IN THE FRYER VESSEL.

Figure 2.4: Fill fryer with filtered oil

2