:rs f.

u: : .... :.:<If service is required, follow these

instructions.

Electrical Shock Hazard

l Disconnect from electrical supply before removing access panel.

l Do not operate dryer without access panel securely in place.

Failure to follow these instructions could result in electrical shock or death.

Lower access panel

wiring diagram location 1. Disconnect

electrical suPPlY-

2. Insert

valve | panel | is hinged i |

| the bottom. | |

3. | Close | lower |

| access | panel. |

Gas shutoff valve “open” and “closed” position

“closed”

position,

gas shutoff valve n closed or “off”

Optional

shutoff valve

Electrical requirements

Electrical Shock Hazard

l Electrical ground is required on this appliance.

lDo Not ground to a gas pipe.

l Do Not modify the power supply cord plug. If it does not fit the outlet, have a proper outlet installed by a qualified electrician.

lDo Not have a fuse in the neutral or grounding circuit. A fuse in the neutral or

grounding circuit could result in an electrical shock.

l Do Not use an extension cord with this appliance.

l Check with a qualified electrician if you are in doubt as to whether the appliance is properly grounded.

Failure to follow these instructions could result in serious injury or death.

If codes permit and a separate grounding wire is used, it is recommended that a qualified electrician determine that the grounding path is adequate.

A 120~volt,

this appliance be provided.

Recommended grounding method

For your personal safety, this appliance must be grounded. This appliance is equipped with a power supply cord having a

PM

\

no 8

00

prow 8 i

Exhaust requirements

Fire/Health Hazard

l Do Not use

lDo Not use metal duct smaller than four inches in diameter.

l Do Not Use exhaust hoods with magnetic latches.

l Check that exhaust system is not longer than specified. Exhaust systems longer than specified will:

-Accumulate lint.

-Shorten the life of the dryer.

-Reduce performance, resulting in longer drying times and increased energy

usage.

Failure to follow specifications may result in a fire.

lDo Not exhaust dryer into a chimney, furnace cold air duct, attic or crawl space, or any other duct used for venting.

l Clean the exhaust system every other year.

l Do Not install flexible duct in enclosed walls, ceilings or f loors.

Accumulated lint could result in a fire or cause moisture damage.

l Exhaust the dryer outside to prevent exposure to substances in the gas fuels and combustion which may be harmful to your health.

The moisture and lint indoors may cause:

-Lint to gather inside and around the dryer and be a fuel for fire.

-Moisture damage to woodwork, furniture, paint, wallpaper, carpet, etc.

-Housecleaning problems and possible health problems.

Failure to follow these instructions could result in fire damage, property damage, personal injury or health problems.

Use duct tape to

seal all joints.

For mobile home installation, the dyer must have an outside exhaust. If you exhaust the dyer through the floor and

the area under your mobile home is enclosed, the exhaust system must terminate outside the enclosed area. Extension beyond the enclosure will prevent lint and moisture

The exhaust duct can be routed up, down, left, right or straight out of the back of the dyer. Detailed space requirements can be found in

“Recessed and closet installation instructions” on Panel C. Use the straightest path you can, where possible, to avoid 90” turns.

Metal flexible duct should be fully extended and supported when the dyer is in final position. DO NOT KINK OR CRUSH THE DUCT. The metal flexible duct must be completely open to allow adequate exhaust air to flow.

An exhaust hood should cap the exhaust duct to prevent exhausted air from returning into dyer. The outlet of the hood must be at least 12 inches from the ground or anything else that may be in the path of the exhaust.

A 44nch outlet hood is preferred. However, a

For permanent installation, a stationary exhaust system is required.

The exhaust outlet is located at the bottom center back of the dyer. Detailed space requirements can be found in the “Recessed and closet installation instructions,” Panel C and on back panel of dyer.

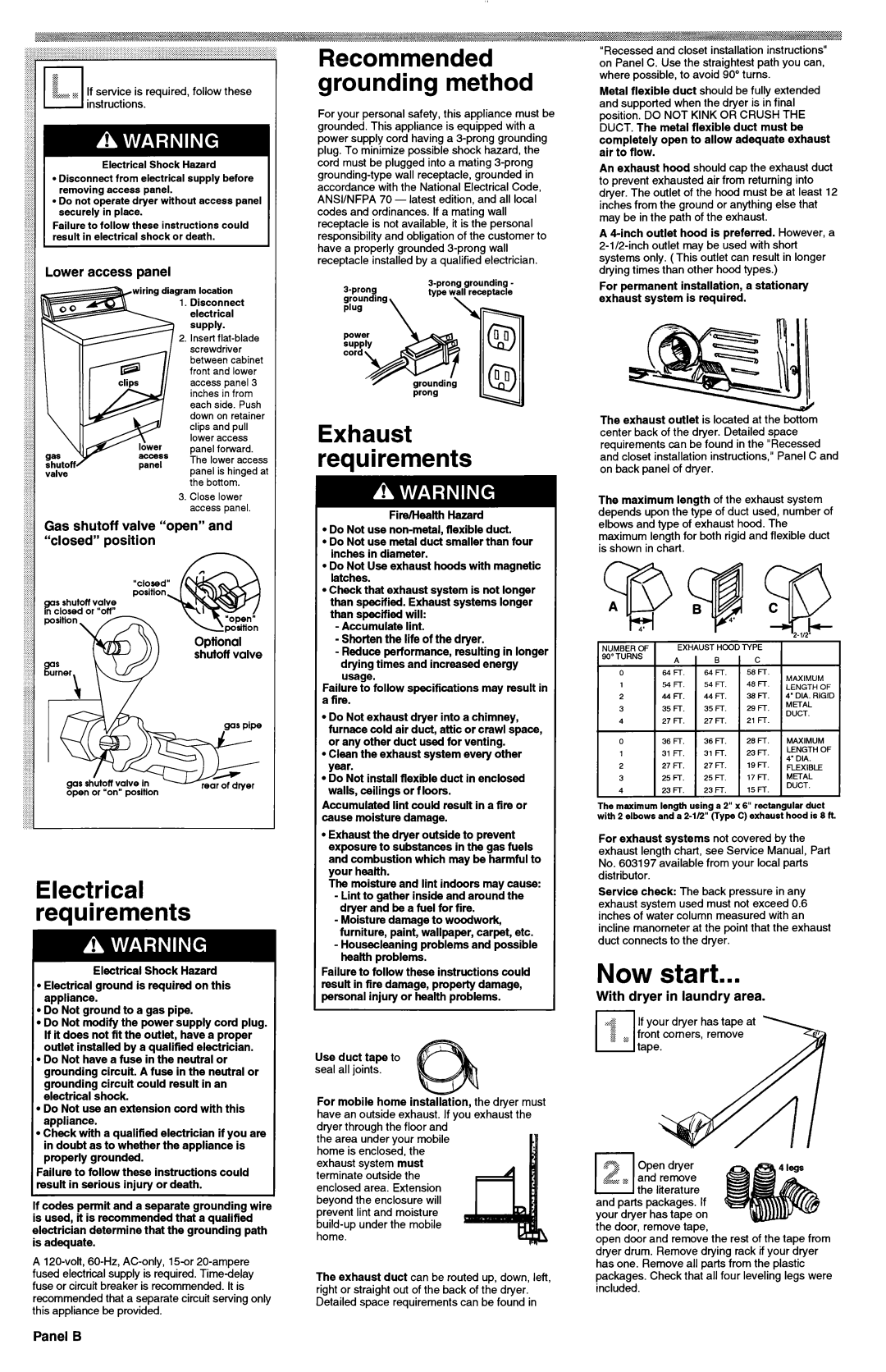

The maximum length of the exhaust system depends upon the type of duct used, number of elbows and type of exhaust hood. The maximum length for both rigid and flexible duct is shown in chart.

Qqvjp

4'

| 1 | 54 | FT. | 54Fr. | 48FT. | MAXIMUM |

| |

| LENGTH | OF | ||||||

|

|

|

|

|

| |||

| 2 | 44Fr. | 44Fr. | 36Fr. | 4' | DIA. | RIGID | |

| 3 | 35 | FT. | 35Fr. | 29Fr. | METAL |

| |

|

|

|

| |||||

| 4 | 27 | FT. | 27FT. | 21 FT. | DUCT. |

| |

|

|

|

| |||||

|

|

|

|

|

| MAXIMUM |

| |

|

|

|

|

|

| LENGTH | OF | |

r | 2031 | 25273136 | FT. | 25FT27Fl31Fr36FT... | 26Fr17FT23FT19 .FT.. . | 4’ | DIA. |

|

FLEXIBLE |

| |||||||

|

|

|

|

|

|

| ||

I |

|

|

|

|

| METAL |

| |

4 | 23 | FT. | 23FT. | 15FT. | DUCT. |

| ||

|

|

| ||||||

The maximum length using a 2” x 6” rectangular duct

with 2 elbows and a

For exhaust systems not covered by the exhaust length chart, see Service Manual, Part No. 603197 available from your local parts distributor.

Service check: The back pressure in any exhaust system used must not exceed 0.6 inches of water column measured with an incline manometer at the point that the exhaust duct connects to the dyer.

Now start...

With..“dryer$in...Slaundry i’area.’

u..v If your dyer has tape at

L

..

B x front comers, remove tape.

ii..$<<5%x

u Open dyer

$& and remove the literature

and parts packages. If your dyer has tape on the door, remove tape,

open door and remove the rest of the tape from dyer drum. Remove dying rack if your dyer has one. Remove all parts from the plastic packages. Check that all four leveling legs were included.

Panel B