Data | Copyright, Eastman Kodak Company, 1999 |

TI2497 Issued |

|

Notice: Observe precautionary information on product labels and on the Material Safety Data Sheets.

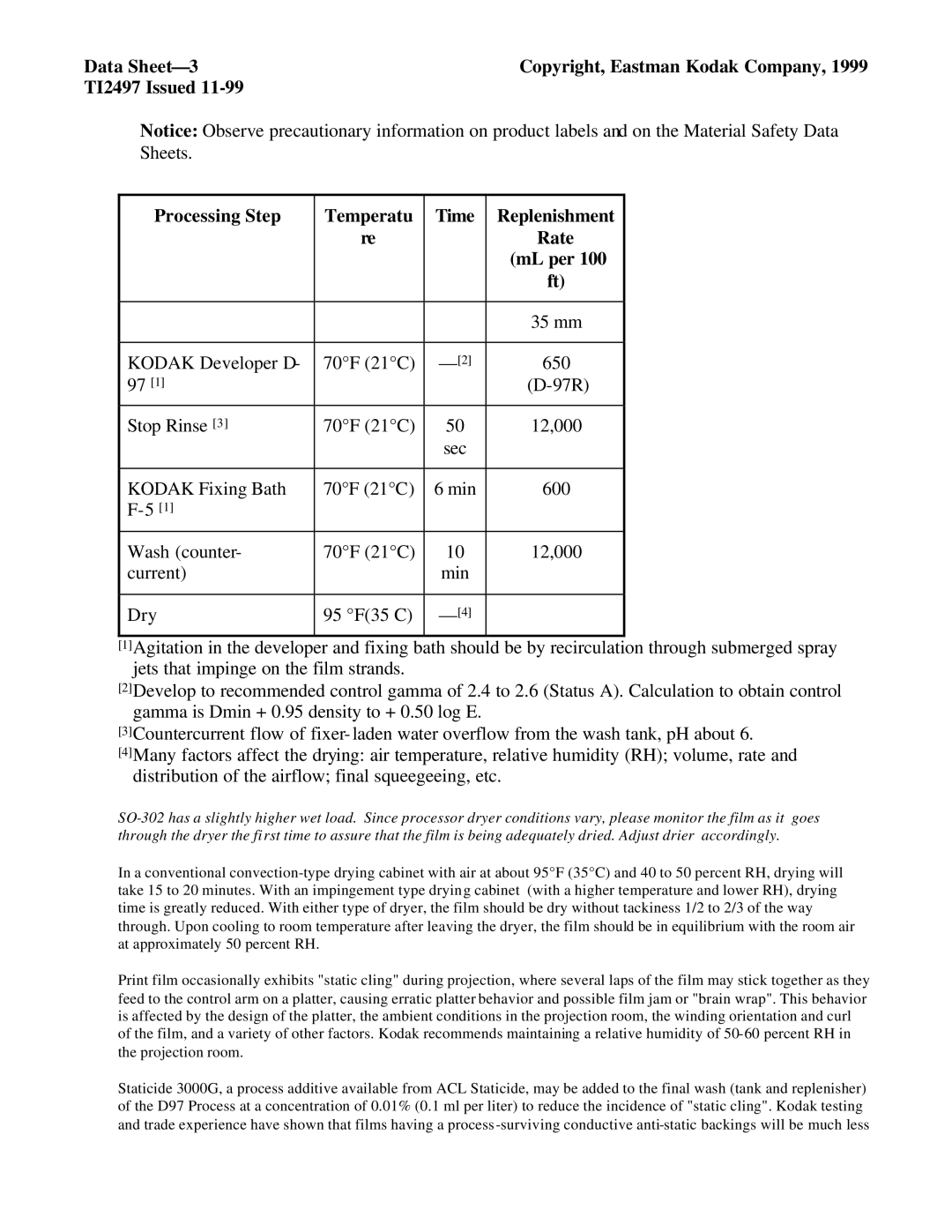

Processing Step | Temperatu | Time | Replenishment |

| re |

| Rate |

|

|

| (mL per 100 |

|

|

| ft) |

|

|

|

|

|

|

| 35 mm |

|

|

|

|

KODAK Developer D- | 70°F (21°C) | 650 | |

97 [1] |

|

| |

Stop Rinse [3] | 70°F (21°C) | 50 | 12,000 |

|

| sec |

|

|

|

|

|

KODAK Fixing Bath | 70°F (21°C) | 6 min | 600 |

|

|

| |

|

|

|

|

Wash (counter- | 70°F (21°C) | 10 | 12,000 |

current) |

| min |

|

|

|

|

|

Dry | 95 °F(35 C) |

|

[1]Agitation in the developer and fixing bath should be by recirculation through submerged spray jets that impinge on the film strands.

[2]Develop to recommended control gamma of 2.4 to 2.6 (Status A). Calculation to obtain control gamma is Dmin + 0.95 density to + 0.50 log E.

[3]Countercurrent flow of fixer- laden water overflow from the wash tank, pH about 6.

[4]Many factors affect the drying: air temperature, relative humidity (RH); volume, rate and distribution of the airflow; final squeegeeing, etc.

In a conventional

Print film occasionally exhibits "static cling" during projection, where several laps of the film may stick together as they feed to the control arm on a platter, causing erratic platter behavior and possible film jam or "brain wrap". This behavior is affected by the design of the platter, the ambient conditions in the projection room, the winding orientation and curl of the film, and a variety of other factors. Kodak recommends maintaining a relative humidity of

Staticide 3000G, a process additive available from ACL Staticide, may be added to the final wash (tank and replenisher) of the D97 Process at a concentration of 0.01% (0.1 ml per liter) to reduce the incidence of "static cling". Kodak testing and trade experience have shown that films having a process