VI. System/Software Setup

Refer to the Matchprint ProofPro or the DirectWorks Suite User’s Guide for the following procedures: Reference Profile: = US_Web_SWOP.icc

Paper Profile in MPPP RIP v1.0: = MPPP2610_600x600_MPDye_MPPPDyePub_v1r1.icc

Paper Profile in MPPP RIP v2.0: = K_13_5533_0N003_031_XRD41_1.icc

Set Kodak Polychrome Graphics CFM to Rendering Intent: = Perceptual, Black Generation: = Retain Integrity if CMYK to CMYK is left

unchecked, use GCR , Total ink: = 310, Black Ink Limit: = 100, Black Generation: = Medium.

Calibrate the KPG Matchprint ProofPro 2610 inkjet printer for use with Matchprint ProofPro Inkjet Media Publication/Dye paper utilizing the file: In MPPP RIP v1.0: = MPPP2610_600x600_MPDye_MPPPDyePub_v1r1.bpl

In MPPP RIP v2.0: = K_13_5533_0N003_031_XRD41_1.epl

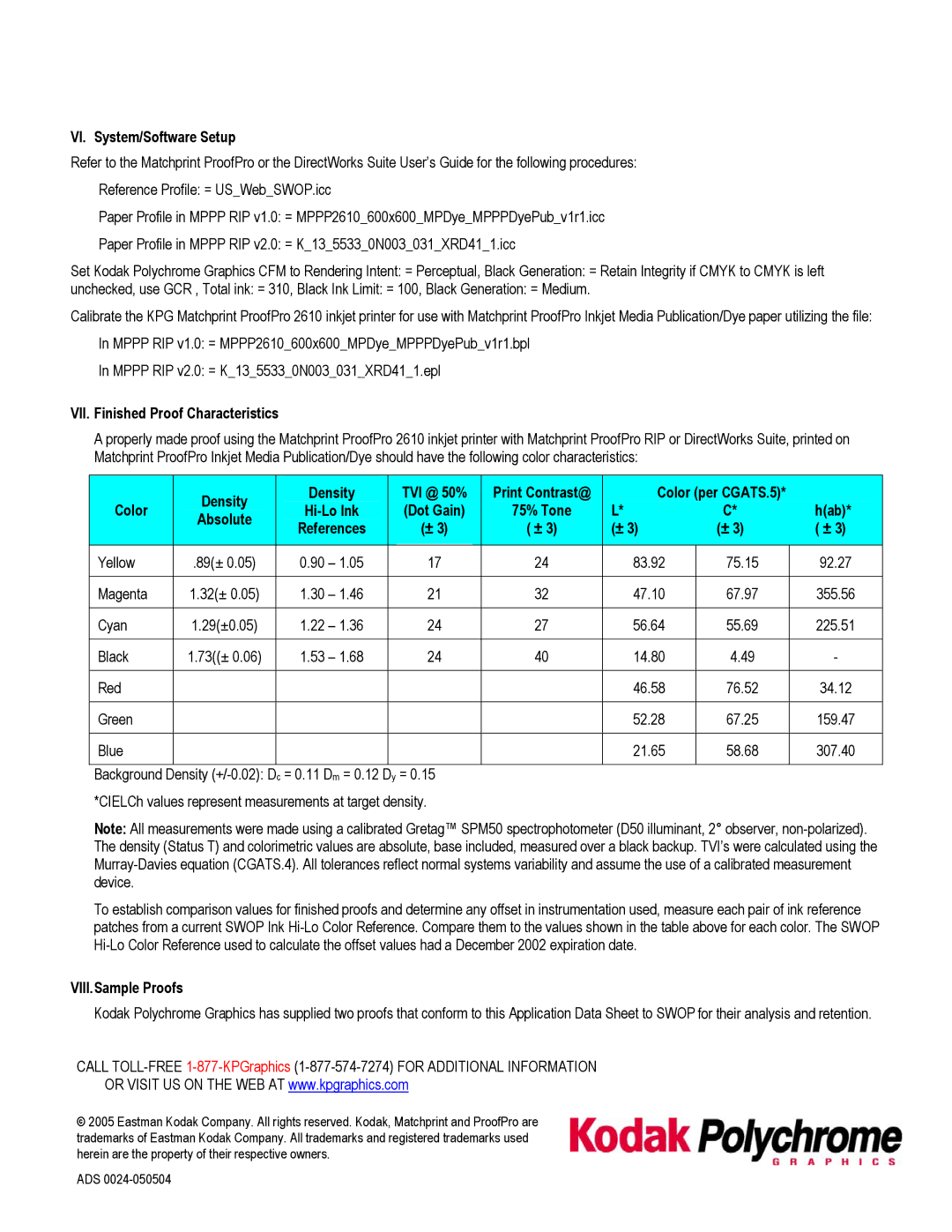

VII. Finished Proof Characteristics

A properly made proof using the Matchprint ProofPro 2610 inkjet printer with Matchprint ProofPro RIP or DirectWorks Suite, printed on Matchprint ProofPro Inkjet Media Publication/Dye should have the following color characteristics:

|

|

| Density |

| Density |

| TVI @ 50% |

| Print Contrast@ |

| Color (per CGATS.5)* |

| |

| Color |

|

|

| (Dot Gain) |

| 75% Tone |

| L* | C* | h(ab)* | ||

|

| Absolute |

|

|

|

| |||||||

|

|

|

| References |

| (± 3) |

| ( ± 3) |

| (± 3) | (± 3) | ( ± 3) | |

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Yellow | .89(± 0.05) |

| 0.90 – 1.05 | 17 | 24 | 83.92 | 75.15 | 92.27 | ||||

|

|

|

|

|

|

|

|

|

| ||||

| Magenta | 1.32(± 0.05) |

| 1.30 – 1.46 | 21 | 32 | 47.10 | 67.97 | 355.56 | ||||

|

|

|

|

|

|

|

|

|

| ||||

| Cyan | 1.29(±0.05) |

| 1.22 – 1.36 | 24 | 27 | 56.64 | 55.69 | 225.51 | ||||

|

|

|

|

|

|

|

|

|

| ||||

| Black | 1.73((± 0.06) |

| 1.53 – 1.68 | 24 | 40 | 14.80 | 4.49 | - | ||||

|

|

|

|

|

|

|

|

|

|

|

|

| |

| Red |

|

|

|

|

|

|

|

| 46.58 | 76.52 | 34.12 | |

|

|

|

|

|

|

|

|

|

|

|

|

| |

| Green |

|

|

|

|

|

|

|

| 52.28 | 67.25 | 159.47 | |

|

|

|

|

|

|

|

|

|

|

|

|

| |

| Blue |

|

|

|

|

|

|

|

| 21.65 | 58.68 | 307.40 | |

Background Density

Note: All measurements were made using a calibrated Gretag™ SPM50 spectrophotometer (D50 illuminant, 2° observer,

To establish comparison values for finished proofs and determine any offset in instrumentation used, measure each pair of ink reference patches from a current SWOP Ink

VIII.Sample Proofs

Kodak Polychrome Graphics has supplied two proofs that conform to this Application Data Sheet to SWOP for their analysis and retention.

CALL

OR VISIT US ON THE WEB AT www.kpgraphics.com

© 2005 Eastman Kodak Company. All rights reserved. Kodak, Matchprint and ProofPro are trademarks of Eastman Kodak Company. All trademarks and registered trademarks used herein are the property of their respective owners.

ADS