![]() Magnus 400 II/ Magnus 400 II Quantum Platesetter specifications

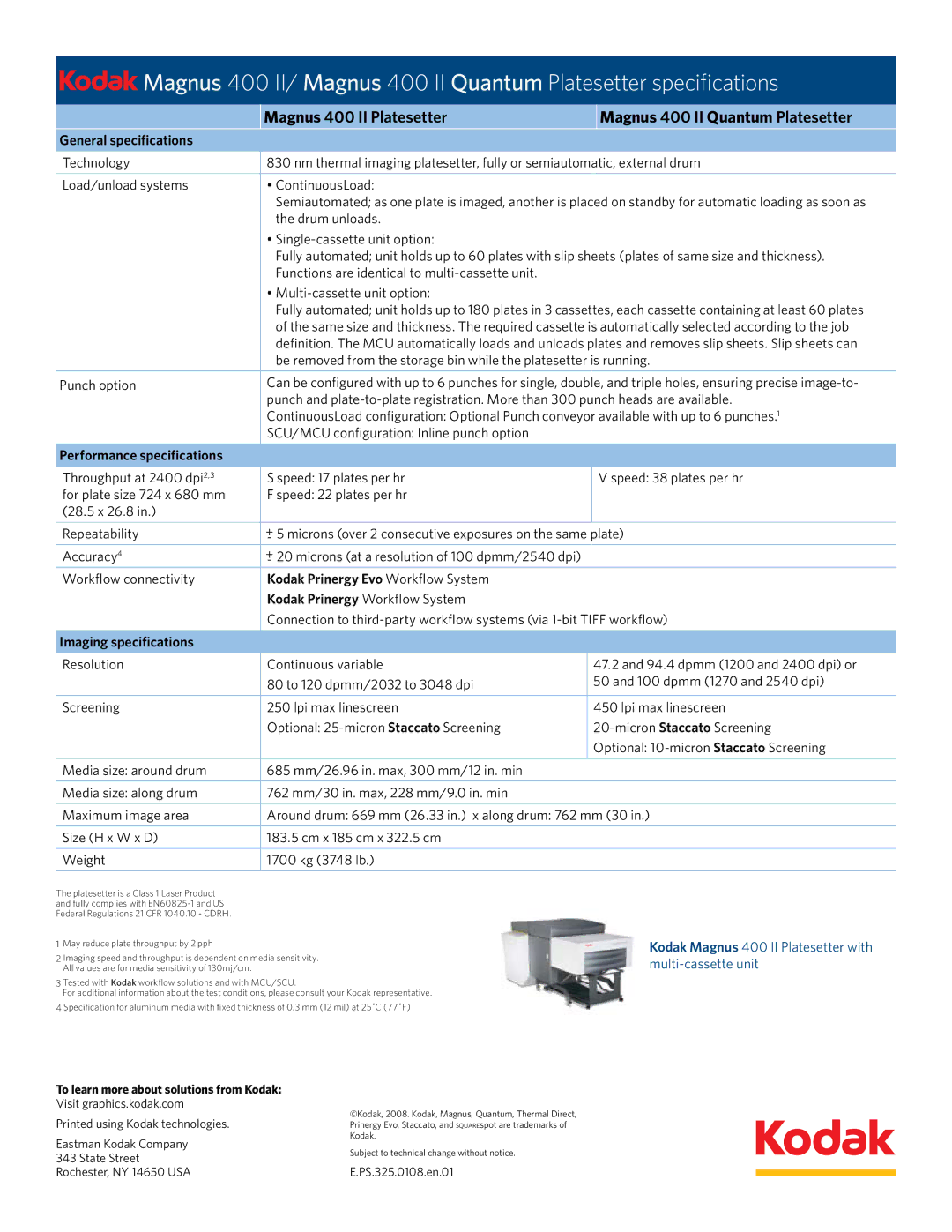

Magnus 400 II/ Magnus 400 II Quantum Platesetter specifications

Magnus 400 II Platesetter

Magnus 400 II Quantum Platesetter

General specifications

Technology | 830 nm thermal imaging platesetter, fully or semiautomatic, external drum | ||

|

|

|

|

Load/unload systems | • ContinuousLoad: |

| |

| Semiautomated; as one plate is imaged, another is placed on standby for automatic loading as soon as | ||

| the drum unloads. |

| |

| • |

| |

| Fully automated; unit holds up to 60 plates with slip sheets (plates of same size and thickness). | ||

| Functions are identical to |

| |

| • |

| |

| Fully automated; unit holds up to 180 plates in 3 cassettes, each cassette containing at least 60 plates | ||

| of the same size and thickness. The required cassette is automatically selected according to the job | ||

| definition. The MCU automatically loads and unloads plates and removes slip sheets. Slip sheets can | ||

| be removed from the storage bin while the platesetter is running. | ||

|

|

|

|

Punch option | Can be configured with up to 6 punches for single, double, and triple holes, ensuring precise | ||

| punch and | ||

| ContinuousLoad configuration: Optional Punch conveyor available with up to 6 punches.1 | ||

| SCU/MCU configuration: Inline punch option |

| |

|

|

|

|

Performance specifications |

|

|

|

|

|

|

|

Throughput at 2400 dpi2,3 | S speed: 17 plates per hr | V speed: 38 plates per hr | |

for plate size 724 x 680 mm | F speed: 22 plates per hr |

| |

(28.5 x 26.8 in.) |

|

|

|

|

|

|

|

Repeatability | +- 5 microns (over 2 consecutive exposures on the same plate) | ||

Accuracy4 | +- 20 microns (at a resolution of 100 dpmm/2540 dpi) |

| |

Workflow connectivity | Kodak Prinergy Evo Workflow System |

| |

| Kodak Prinergy Workflow System |

| |

| Connection to | ||

|

|

|

|

Imaging specifications |

|

|

|

|

|

|

|

Resolution | Continuous variable |

| 47.2 and 94.4 dpmm (1200 and 2400 dpi) or |

| 80 to 120 dpmm/2032 to 3048 dpi |

| 50 and 100 dpmm (1270 and 2540 dpi) |

|

|

|

|

Screening | 250 lpi max linescreen |

| 450 lpi max linescreen |

| Optional: |

| |

|

|

| Optional: |

|

|

|

|

Media size: around drum | 685 mm/26.96 in. max, 300 mm/12 in. min |

| |

|

|

| |

Media size: along drum | 762 mm/30 in. max, 228 mm/9.0 in. min |

| |

|

| ||

Maximum image area | Around drum: 669 mm (26.33 in.) x along drum: 762 mm (30 in.) | ||

|

|

| |

Size (H x W x D) | 183.5 cm x 185 cm x 322.5 cm |

| |

|

|

| |

Weight | 1700 kg (3748 lb.) |

| |

|

|

|

|

The platesetter is a Class 1 Laser Product and fully complies with

1May reduce plate throughput by 2 pph

2Imaging speed and throughput is dependent on media sensitivity. All values are for media sensitivity of 130mj/cm.

3Tested with Kodak workflow solutions and with MCU/SCU.

For additional information about the test conditions, please consult your Kodak representative.

4Specification for aluminum media with fixed thickness of 0.3 mm (12 mil) at 25˚C (77˚F)

To learn more about solutions from Kodak:

Visit graphics.kodak.com

Printed using Kodak technologies. | ©Kodak, 2008. Kodak, Magnus, Quantum, Thermal Direct, | |

Prinergy Evo, Staccato, and squarespot are trademarks of | ||

Eastman Kodak Company | Kodak. | |

Subject to technical change without notice. | ||

343 State Street | ||

| ||

Rochester, NY 14650 USA | E.PS.325.0108.en.01 |

Kodak Magnus 400 II Platesetter with