SETTING THE SPEED

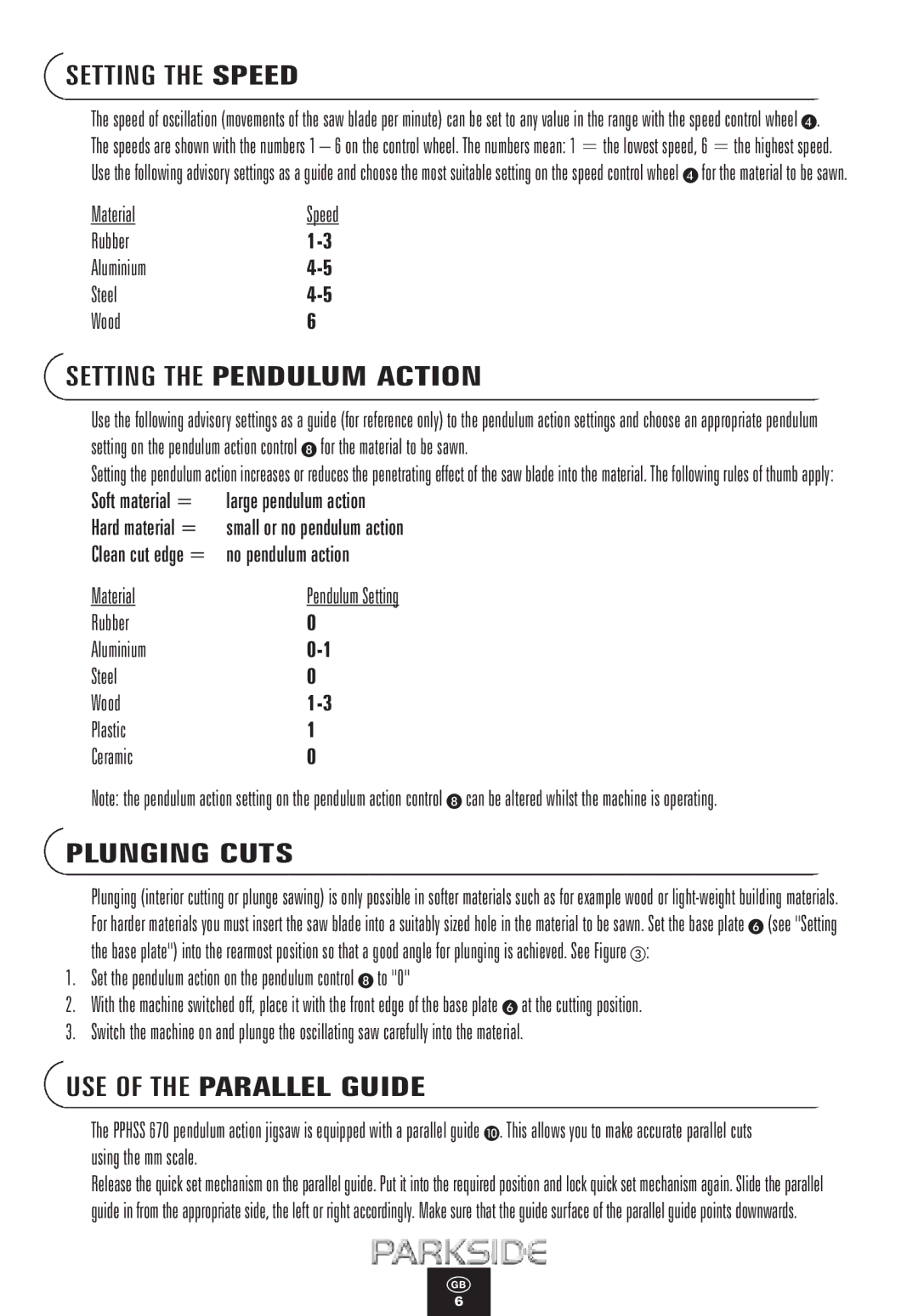

The speed of oscillation (movements of the saw blade per minute) can be set to any value in the range with the speed control wheel . The speeds are shown with the numbers 1 – 6 on the control wheel. The numbers mean: 1 = the lowest speed, 6 = the highest speed.

Use the following advisory settings as a guide and choose the most suitable setting on the speed control wheel | for the material to be sawn. | |

Material | Speed |

|

Rubber |

| |

Aluminium |

| |

Steel |

| |

Wood | 6 |

|

SETTING THE PENDULUM ACTION

Use the following advisory settings as a guide (for reference only) to the pendulum action settings and choose an appropriate pendulum setting on the pendulum action control for the material to be sawn.

Setting the pendulum action increases or reduces the penetrating effect of the saw blade into the material. The following rules of thumb apply:

Soft material = | large pendulum action |

Hard material = | small or no pendulum action |

Clean cut edge = | no pendulum action |

Material | Pendulum Setting |

Rubber | 0 |

Aluminium | |

Steel | 0 |

Wood | |

Plastic | 1 |

Ceramic | 0 |

| Note: the pendulum action setting on the pendulum action control | can be altered whilst the machine is operating. |

| ||

|

|

|

|

| |

PLUNGING CUTS |

|

|

|

| |

|

| ||||

| Plunging (interior cutting or plunge sawing) is only possible in softer materials such as for example wood or | ||||

| For harder materials you must insert the saw blade into a suitably sized hole in the material to be sawn. Set the base plate | (see "Setting | |||

| the base plate") into the rearmost position so that a good angle for plunging is achieved. See Figure : |

| |||

1. | Set the pendulum action on the pendulum control | to "0" |

|

|

|

2. | With the machine switched off, place it with the front edge of the base plate | at the cutting position. |

| ||

3. | Switch the machine on and plunge the oscillating saw carefully into the material. |

| |||

|

|

|

| ||

USE OF THE PARALLEL GUIDE |

|

|

| ||

|

|

|

| ||

| The PPHSS 670 pendulum action jigsaw is equipped with a parallel guide | . This allows you to make accurate parallel cuts |

| ||

| using the mm scale. |

|

|

|

|

Release the quick set mechanism on the parallel guide. Put it into the required position and lock quick set mechanism again. Slide the parallel guide in from the appropriate side, the left or right accordingly. Make sure that the guide surface of the parallel guide points downwards.

6