World’s fastest dry imager(*1)

World’s fastest dry imager(*1)

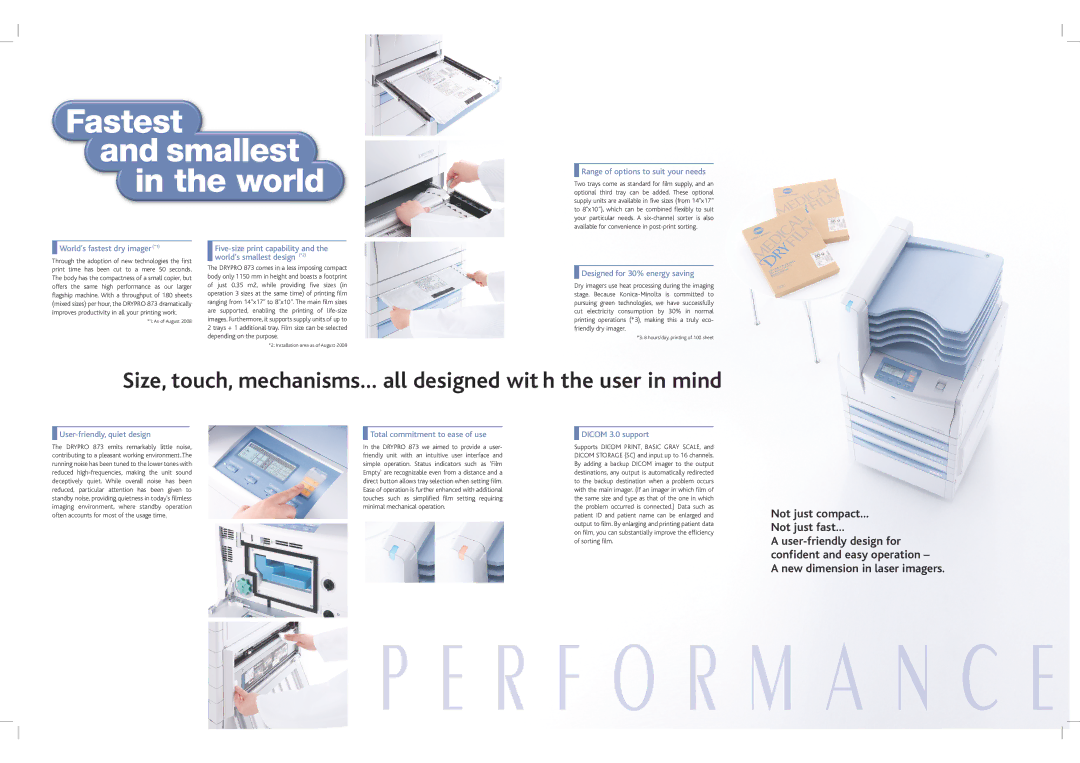

Through the adoption of new technologies the first print time has been cut to a mere 50 seconds. The body has the compactness of a small copier, but offers the same high performance as our larger flagship machine. With a throughput of 180 sheets (mixed sizes) per hour,the DRYPRO 873 dramatically improves productivity in all your printing work.

*1:As of August 2008

The DRYPRO 873 comes in a less imposing compact body only 1150 mm in height and boasts a footprint of just 0.35 m2, while providing five sizes (in operation 3 sizes at the same time) of printing film ranging from 14"x17” to 8"x10”. The main film sizes are supported, enabling the printing of

*2: Installation area as of August 2008

Range of options to suit your needs

Range of options to suit your needs

Two trays come as standard for film supply, and an optional third tray can be added. These optional supply units are available in five sizes (from 14"x17” to 8"x10”), which can be combined flexibly to suit your particular needs. A

Designed for 30% energy saving

Designed for 30% energy saving

Dry imagers use heat processing during the imaging stage. Because

*3: 8 hours/day, printing of 100 sheet

Size,touch, mechanisms… all designed with the user in mind

User-friendly,quiet design

The DRYPRO 873 emits remarkably little noise, contributing to a pleasant working environment.The running noise has been tuned to the lower tones with reduced

Total commitment to ease of use

Total commitment to ease of use

In the DRYPRO 873 we aimed to provide a user- friendly unit with an intuitive user interface and simple operation. Status indicators such as 'Film Empty' are recognizable even from a distance and a direct button allows tray selection when setting film. Ease of operation is further enhanced with additional touches such as simplified film setting requiring minimal mechanical operation.

DICOM 3.0 support

DICOM 3.0 support

Supports DICOM PRINT, BASIC GRAY SCALE, and DICOM STORAGE (SC) and input up to 16 channels. By adding a backup DICOM imager to the output destinations, any output is automatically redirected to the backup destination when a problem occurs with the main imager. (If an imager in which film of the same size and type as that of the one in which the problem occurred is connected.) Data such as patient ID and patient name can be enlarged and output to film. By enlarging and printing patient data on film, you can substantially improve the efficiency of sorting film.

Not just compact… Not just fast…

A