ComponentsOperation

The pump is worked by a single full movement; by pressing the dispenser head downwards a 1/30 fl. Oz. of liquid will be expelled. When first used it may be necessary to prime the pump with several movements. Note: This dispenser is NOT designed for use with soaps which contain suspended particles. If these soaps are used it will affect the working parts of the dispenser and will negate the warranty.

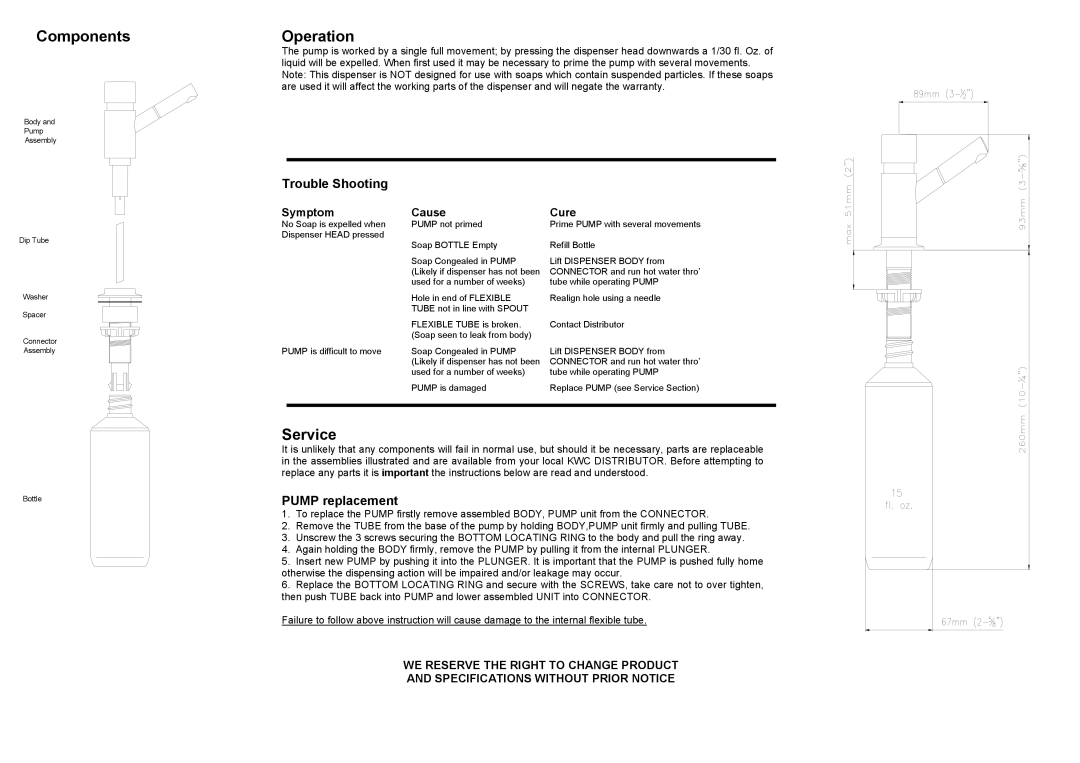

Body and

Pump

Assembly

Dip Tube

Washer

Spacer

Connector Assembly

Trouble Shooting

Symptom

No Soap is expelled when Dispenser HEAD pressed

PUMP is difficult to move

Cause

PUMP not primed

Soap BOTTLE Empty

Soap Congealed in PUMP (Likely if dispenser has not been used for a number of weeks)

Hole in end of FLEXIBLE TUBE not in line with SPOUT

FLEXIBLE TUBE is broken. (Soap seen to leak from body)

Soap Congealed in PUMP (Likely if dispenser has not been used for a number of weeks)

PUMP is damaged

Cure

Prime PUMP with several movements

Refill Bottle

Lift DISPENSER BODY from CONNECTOR and run hot water thro’ tube while operating PUMP

Realign hole using a needle

Contact Distributor

Lift DISPENSER BODY from CONNECTOR and run hot water thro’ tube while operating PUMP

Replace PUMP (see Service Section)

| Service | |

| It is unlikely that any components will fail in normal use, but should it be necessary, parts are replaceable | |

| in the assemblies illustrated and are available from your local KWC DISTRIBUTOR. Before attempting to | |

| replace any parts it is important the instructions below are read and understood. | |

Bottle | PUMP replacement | |

|

| |

| 1. | To replace the PUMP firstly remove assembled BODY, PUMP unit from the CONNECTOR. |

| 2. | Remove the TUBE from the base of the pump by holding BODY,PUMP unit firmly and pulling TUBE. |

| 3. | Unscrew the 3 screws securing the BOTTOM LOCATING RING to the body and pull the ring away. |

| 4. | Again holding the BODY firmly, remove the PUMP by pulling it from the internal PLUNGER. |

| 5. | Insert new PUMP by pushing it into the PLUNGER. It is important that the PUMP is pushed fully home |

| otherwise the dispensing action will be impaired and/or leakage may occur. | |

| 6. | Replace the BOTTOM LOCATING RING and secure with the SCREWS, take care not to over tighten, |

then push TUBE back into PUMP and lower assembled UNIT into CONNECTOR. Failure to follow above instruction will cause damage to the internal flexible tube.

WE RESERVE THE RIGHT TO CHANGE PRODUCT

AND SPECIFICATIONS WITHOUT PRIOR NOTICE