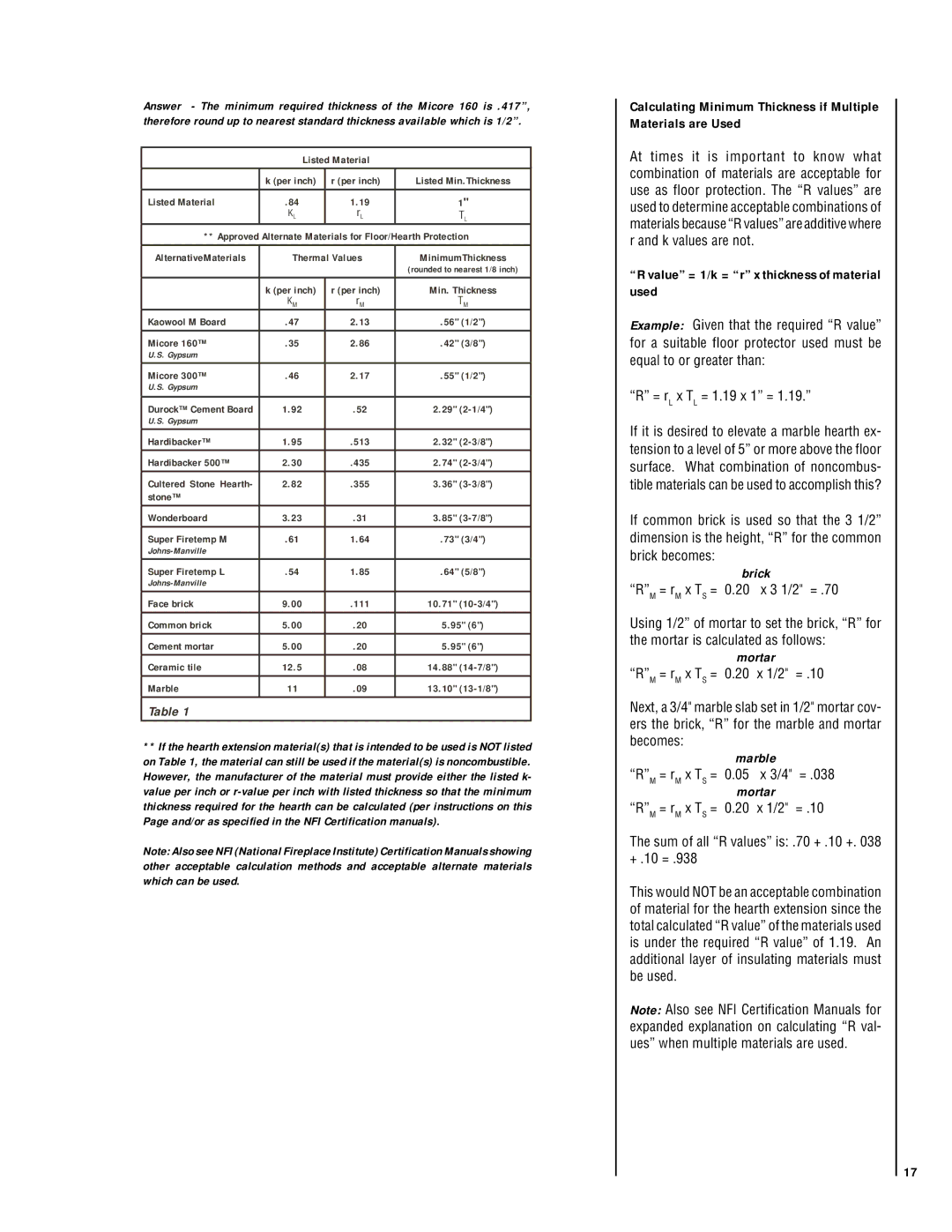

Answer - The minimum required thickness of the Micore 160 is .417”, therefore round up to nearest standard thickness available which is 1/2”.

Listed Material

| k (per inch) | r (per inch) | Listed Min.Thickness |

|

|

|

|

Listed Material | .84 | 1.19 | 1" |

| KL | rL | TL |

** Approved Alternate Materials for Floor/Hearth Protection | |||

|

|

| |

AlternativeMaterials | Thermal Values | MinimumThickness | |

|

|

| (rounded to nearest 1/8 inch) |

|

|

|

|

| k (per inch) | r (per inch) | Min. Thickness |

| KM | rM | TM |

Kaowool M Board | .47 | 2.13 | .56" (1/2") |

|

|

|

|

Micore 160™ | .35 | 2.86 | .42" (3/8") |

U.S. Gypsum |

|

|

|

|

|

|

|

Micore 300™ | .46 | 2.17 | .55" (1/2") |

U.S. Gypsum |

|

|

|

|

|

|

|

Durock™ Cement Board | 1.92 | .52 | 2.29" |

U.S. Gypsum |

|

|

|

|

|

|

|

Hardibacker™ | 1.95 | .513 | 2.32" |

Hardibacker 500™ | 2.30 | .435 | 2.74" |

Cultered Stone Hearth- | 2.82 | .355 | 3.36" |

stone™ |

|

|

|

|

|

|

|

Wonderboard | 3.23 | .31 | 3.85" |

|

|

|

|

Super Firetemp M | .61 | 1.64 | .73" (3/4") |

|

|

| |

|

|

|

|

Super Firetemp L | .54 | 1.85 | .64" (5/8") |

|

|

| |

|

|

|

|

Face brick | 9.00 | .111 | 10.71" |

Common brick | 5.00 | .20 | 5.95" (6") |

Cement mortar | 5.00 | .20 | 5.95" (6") |

|

|

|

|

Ceramic tile | 12.5 | .08 | 14.88" |

|

|

|

|

Marble | 11 | .09 | 13.10" |

|

|

|

|

Table 1 |

|

|

|

**If the hearth extension material(s) that is intended to be used is NOT listed on Table 1, the material can still be used if the material(s) is noncombustible. However, the manufacturer of the material must provide either the listed k- value per inch or

Note: Also see NFI (National Fireplace Institute) Certification Manuals showing other acceptable calculation methods and acceptable alternate materials which can be used.

Calculating Minimum Thickness if Multiple Materials are Used

At times it is important to know what combination of materials are acceptable for use as floor protection. The “R values” are used to determine acceptable combinations of materials because “R values” are additive where r and k values are not.

“R value” = 1/k = “r” x thickness of material used

Example: Given that the required “R value” for a suitable floor protector used must be equal to or greater than:

“R” = rL x TL = 1.19 x 1” = 1.19.”

If it is desired to elevate a marble hearth ex- tension to a level of 5” or more above the floor surface. What combination of noncombus- tible materials can be used to accomplish this?

If common brick is used so that the 3 1/2” dimension is the height, “R” for the common brick becomes:

brick

“R”M = rM x TS = 0.20 x 3 1/2" = .70

Using 1/2” of mortar to set the brick, “R” for the mortar is calculated as follows:

mortar

“R”M = rM x TS = 0.20 x 1/2" = .10

Next, a 3/4" marble slab set in 1/2" mortar cov- ers the brick, “R” for the marble and mortar becomes:

marble

“R”M = rM x TS = 0.05 x 3/4" = .038

mortar

“R”M = rM x TS = 0.20 x 1/2" = .10

The sum of all “R values” is: .70 + .10 +. 038 + .10 = .938

This would NOT be an acceptable combination of material for the hearth extension since the total calculated “R value” of the materials used is under the required “R value” of 1.19. An additional layer of insulating materials must be used.

Note: Also see NFI Certification Manuals for expanded explanation on calculating “R val- ues” when multiple materials are used.

17