ML180DFE SERIES specifications

Lennox International Inc. is recognized for its innovative heating and cooling solutions, and the ML180DFE series is no exception. This high-efficiency gas furnace represents a significant leap in residential heating technology, designed to provide optimal home comfort while maximizing energy savings.At the core of the ML180DFE series is its superior efficiency rating of up to 80% Annual Fuel Utilization Efficiency (AFUE). This ensures that a higher proportion of the fuel consumed is converted into heat for the home, minimizing waste and lowering energy bills. Homeowners can appreciate the tangible financial benefits of this efficiency, especially in areas with colder climates where heating costs can rise dramatically.

One of the standout features of the ML180DFE series is its two-stage heating capability. This technology enables the furnace to operate at two different levels of heat output, allowing it to adjust to the heating demands of the home more effectively. By running at a lower capacity on mild days and boosting to full capacity during extreme cold, the furnace delivers more consistent indoor temperatures and reduces the frequent on-and-off cycling that can wear out the system over time.

The ML180DFE series also utilizes a high-efficiency DC motor. This motor not only improves energy efficiency but also enhances the overall comfort of the home. It operates quietly, ensuring minimal disruption while providing reliable heat.

Safety is always a priority with Lennox products, and the ML180DFE series includes a range of safety features. These include a robust heat exchanger designed to withstand high temperatures and a safety shut-off system that reacts in case of any operational irregularities, offering peace of mind for homeowners.

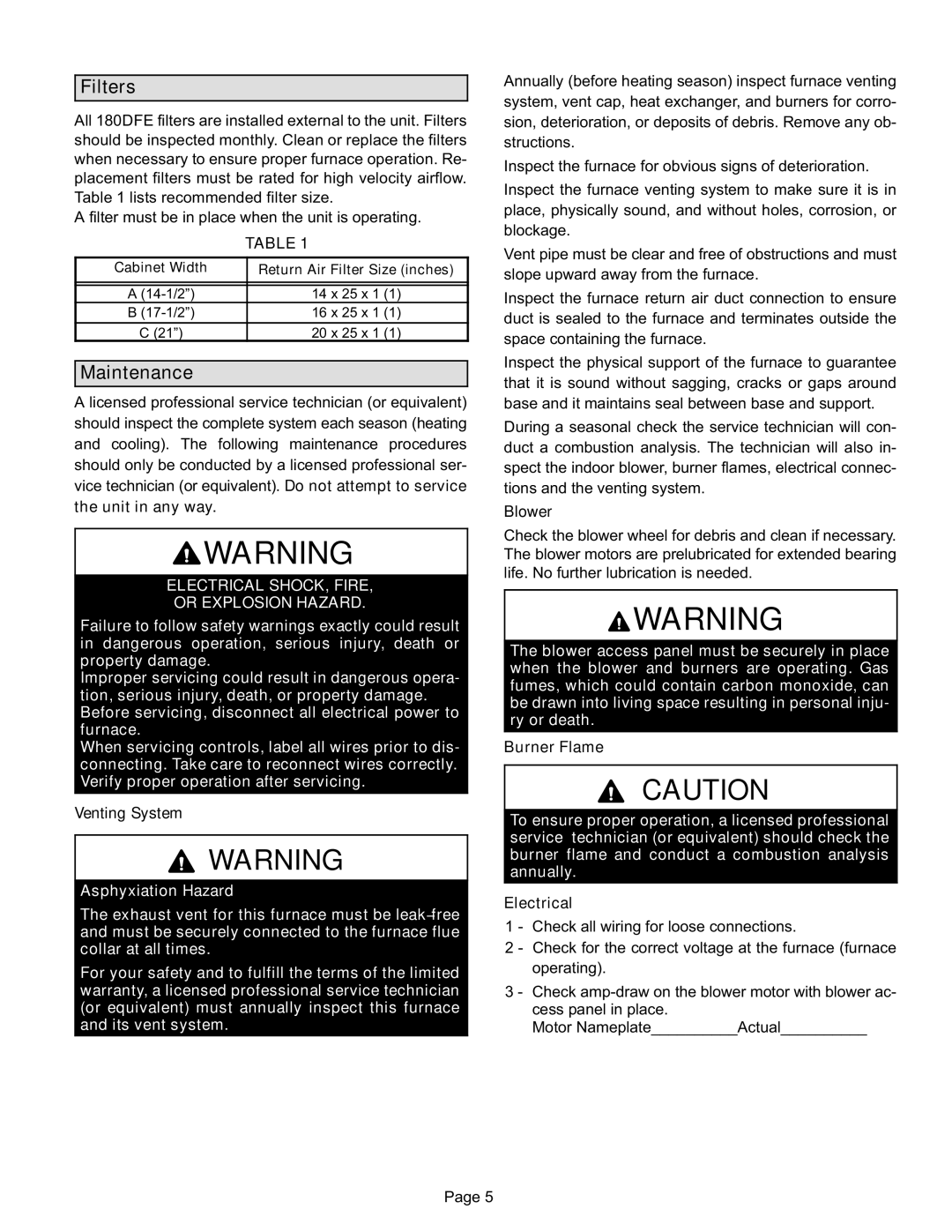

The unit is also designed for easy installation and serviceability, featuring a durable cabinet and accessible components for routine maintenance. Lennox ensures that customers aren’t just buying a furnace, but a long-term heating solution that will serve them well for years to come.

In conclusion, the Lennox ML180DFE series is an excellent choice for homeowners seeking a reliable, efficient, and safe heating solution. With its two-stage heating, high-efficiency ratings, and advanced technologies, this furnace embodies the company’s commitment to quality and innovation, ensuring comfort and satisfaction in every home.