7. Adjustment of White Balance

7-1. Required Equipment

(1)Color analyzer

(2)Automatic adjustor (with automatic adjustment necessity and the

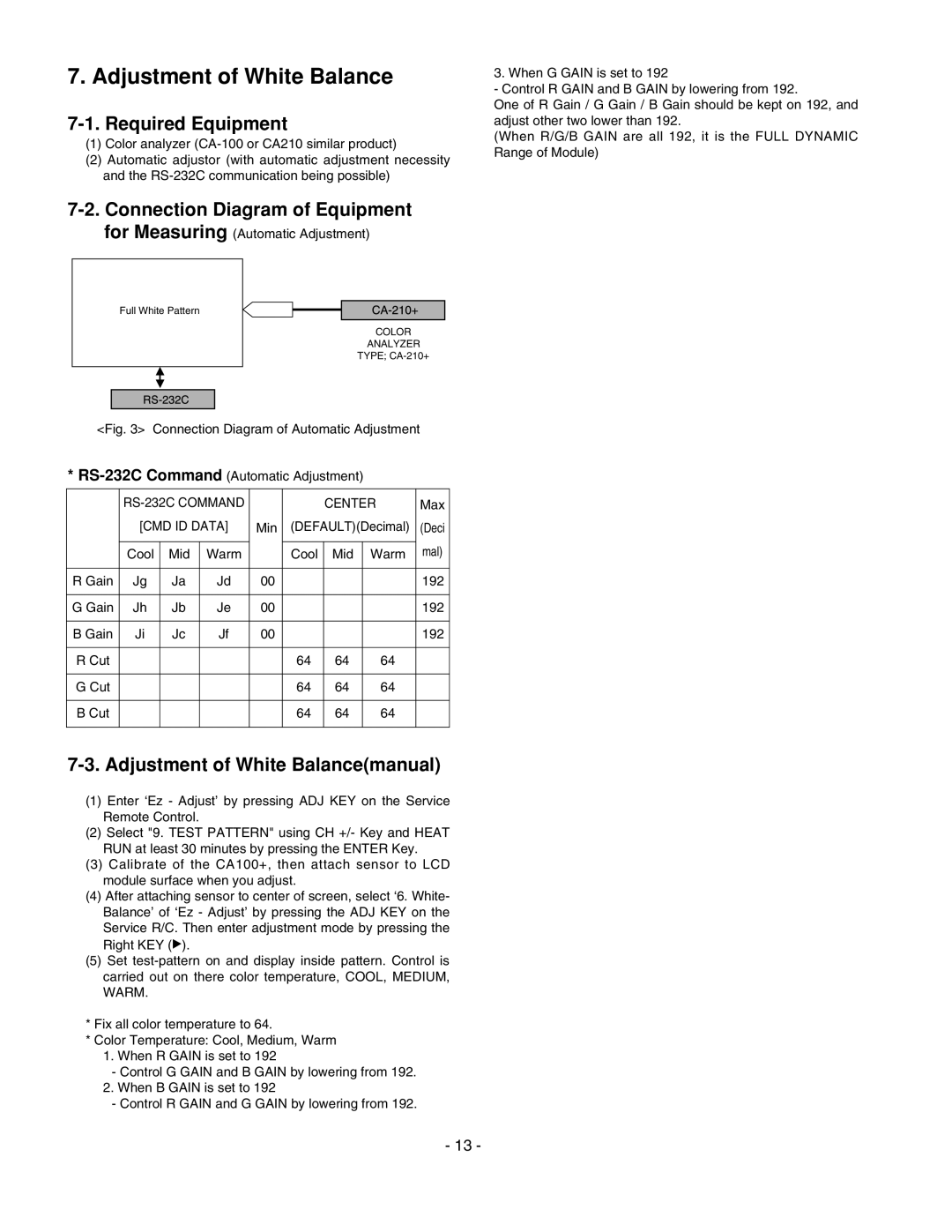

7-2. Connection Diagram of Equipment

for Measuring (Automatic Adjustment)

Full White Pattern

COLOR

ANALYZER

TYPE;

<Fig. 3> Connection Diagram of Automatic Adjustment

*RS-232C Command (Automatic Adjustment)

|

|

| CENTER | Max | ||||

| [CMD ID DATA] | Min | (DEFAULT)(Decimal) | (Deci | ||||

|

|

|

|

|

|

|

| mal) |

| Cool | Mid | Warm |

| Cool | Mid | Warm | |

|

|

|

|

|

|

|

|

|

R Gain | Jg | Ja | Jd | 00 |

|

|

| 192 |

|

|

|

|

|

|

|

|

|

G Gain | Jh | Jb | Je | 00 |

|

|

| 192 |

|

|

|

|

|

|

|

|

|

B Gain | Ji | Jc | Jf | 00 |

|

|

| 192 |

|

|

|

|

|

|

|

|

|

R Cut |

|

|

|

| 64 | 64 | 64 |

|

|

|

|

|

|

|

|

|

|

G Cut |

|

|

|

| 64 | 64 | 64 |

|

|

|

|

|

|

|

|

|

|

B Cut |

|

|

|

| 64 | 64 | 64 |

|

|

|

|

|

|

|

|

|

|

7-3. Adjustment of White Balance(manual)

(1)Enter ‘Ez - Adjust’ by pressing ADJ KEY on the Service Remote Control.

(2)Select "9. TEST PATTERN" using CH +/- Key and HEAT RUN at least 30 minutes by pressing the ENTER Key.

(3)Calibrate of the CA100+, then attach sensor to LCD module surface when you adjust.

(4)After attaching sensor to center of screen, select ‘6. White- Balance’ of ‘Ez - Adjust’ by pressing the ADJ KEY on the Service R/C. Then enter adjustment mode by pressing the Right KEY (G).

(5)Set

*Fix all color temperature to 64.

*Color Temperature: Cool, Medium, Warm

1.When R GAIN is set to 192

-Control G GAIN and B GAIN by lowering from 192.

2.When B GAIN is set to 192

-Control R GAIN and G GAIN by lowering from 192.

3. When G GAIN is set to 192

- Control R GAIN and B GAIN by lowering from 192.

One of R Gain / G Gain / B Gain should be kept on 192, and adjust other two lower than 192.

(When R/G/B GAIN are all 192, it is the FULL DYNAMIC Range of Module)

- 13 -