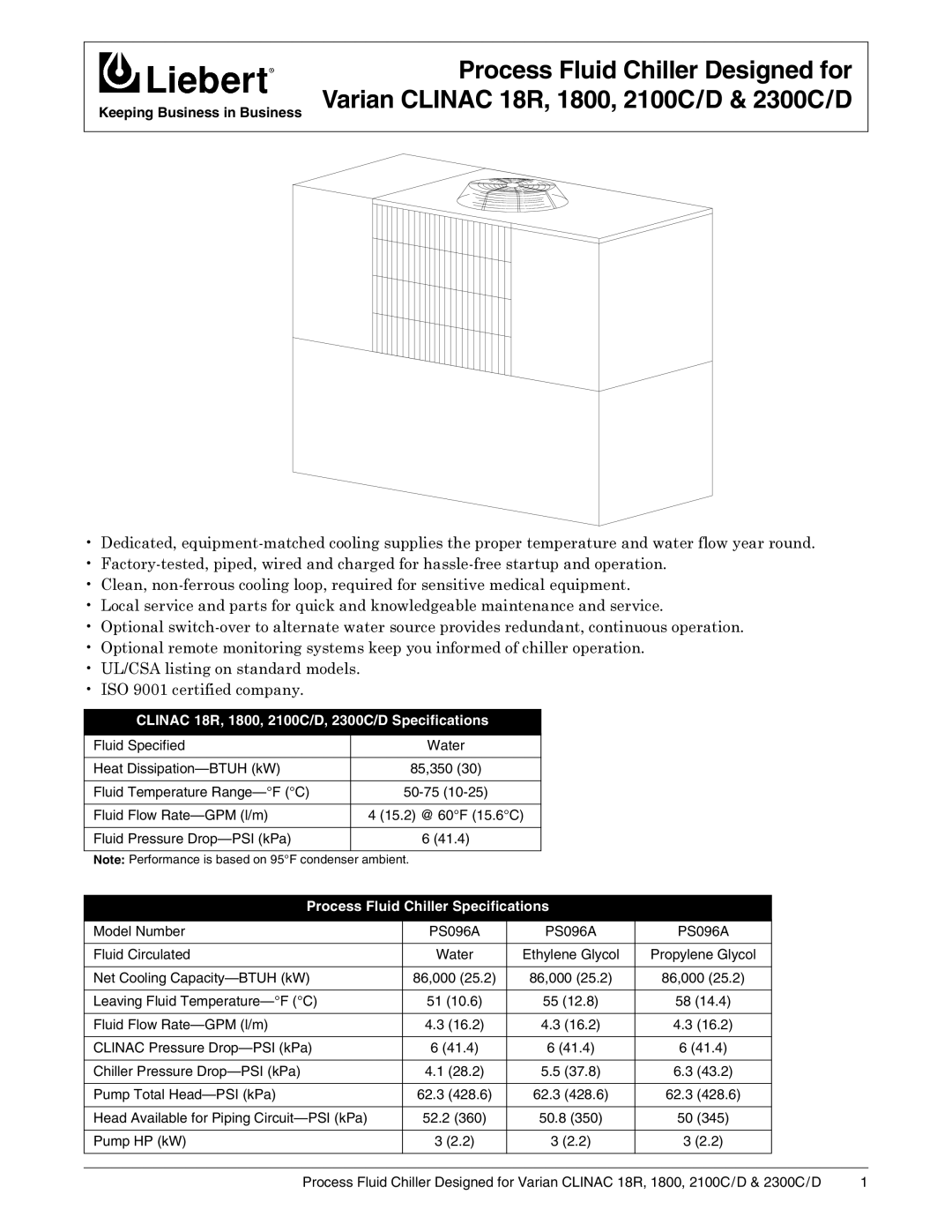

2300C/D, CLINAC 18R, 2100C/D, 1800 specifications

The Liebert 1800, 2100C/D, CLINAC 18R, and 2300C/D are advanced solutions in the realm of precision cooling and power management for IT and telecommunications infrastructure. These systems are designed to enhance operational efficiency, providing reliable performance under demanding conditions.The Liebert 1800 series is known for its modular and scalable design, making it an ideal choice for data centers requiring flexibility in cooling capabilities. One of its key features is the use of dynamic cooling technology, which adjusts the cooling output based on real-time load requirements. This not only maximizes energy efficiency but also extends the lifespan of the equipment by preventing overheating.

The Liebert 2100C/D models further enhance this flexibility with advanced monitoring and control systems. These units come equipped with an intuitive interface that allows for remote management, giving operators comprehensive insight into system performance and environmental conditions. Features such as variable speed fans and digital scroll compressors contribute to significant energy savings, while multiple airflow configurations ensure optimal cooling distribution throughout the facility.

The CLINAC 18R stands out in the realm of medical and industrial applications. This system is specifically designed to provide superior cooling in radiation oncology, ensuring the precise temperature control necessary for sensitive equipment. It features advanced filtration technology, reducing airborne contaminants, which is crucial in healthcare environments. The CLINAC 18R also incorporates a fail-safe operation mode, ensuring continuous performance even in the event of a component failure.

The Liebert 2300C/D system takes resilience to the next level with its built-in redundancy and fault-tolerant design. These units are engineered to handle critical applications, providing uninterrupted cooling even under extreme conditions. The enhanced control algorithms optimize energy consumption while maintaining consistent temperature levels.

All of these Liebert solutions integrate seamlessly with existing infrastructure, showcasing compatibility with various monitoring platforms and building management systems. With a strong focus on sustainability and energy efficiency, these models help businesses reduce their carbon footprint while ensuring the stability of their operations. This combination of features makes the Liebert 1800, 2100C/D, CLINAC 18R, and 2300C/D an ideal choice for organizations looking to optimize their cooling and power management systems.