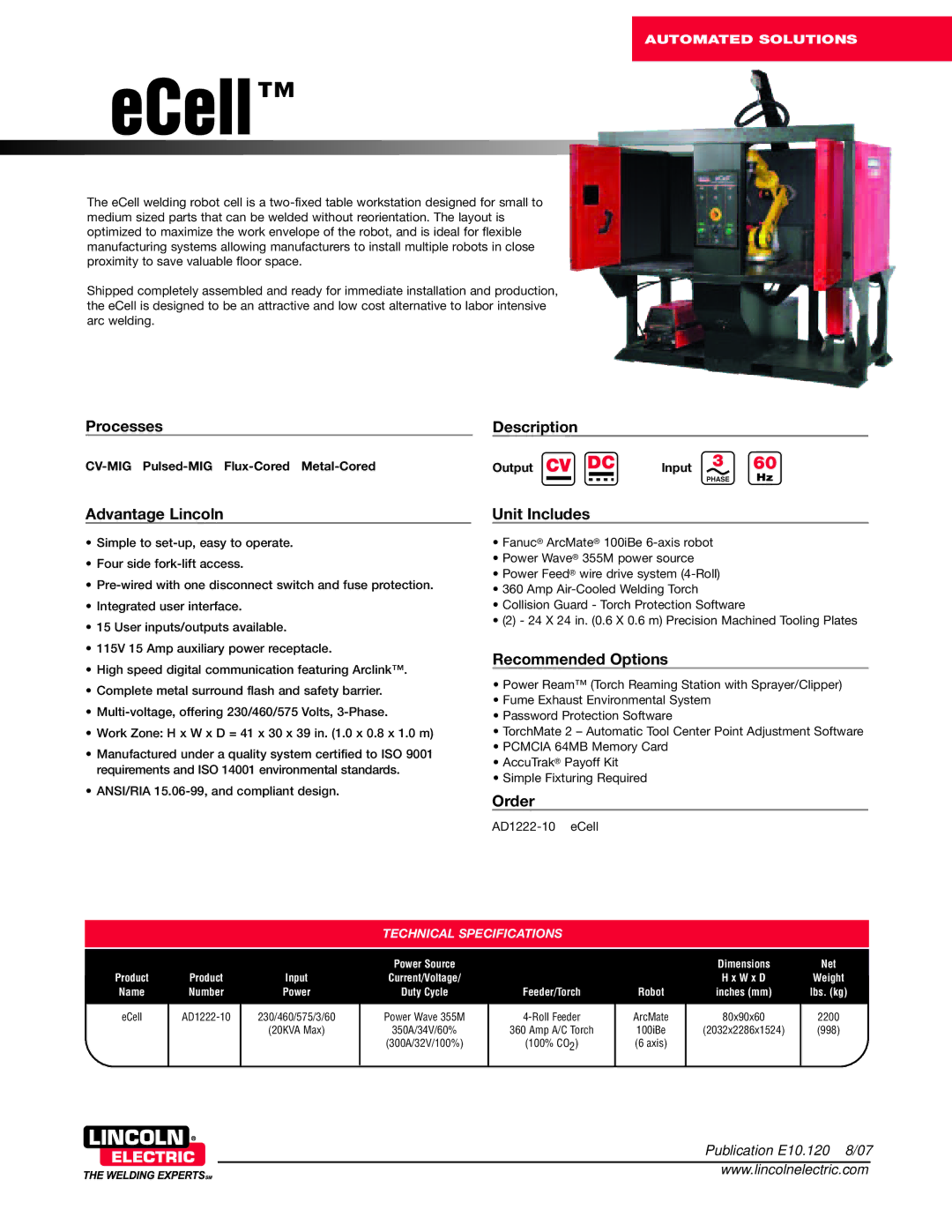

eCell™

AUTOMATED SOLUTIONS

The eCell welding robot cell is a

Shipped completely assembled and ready for immediate installation and production, the eCell is designed to be an attractive and low cost alternative to labor intensive arc welding.

Processes

Advantage Lincoln

•Simple to

•Four side

•

•Integrated user interface.

•15 User inputs/outputs available.

•115V 15 Amp auxiliary power receptacle.

•High speed digital communication featuring Arclink™.

•Complete metal surround flash and safety barrier.

•

•Work Zone: H x W x D = 41 x 30 x 39 in. (1.0 x 0.8 x 1.0 m)

•Manufactured under a quality system certified to ISO 9001 requirements and ISO 14001 environmental standards.

•ANSI/RIA

Description

Output CV DC | Input 3 | 60 |

| PHASE | Hz |

Unit Includes

•Fanuc® ArcMate® 100iBe

•Power Wave® 355M power source

•Power Feed® wire drive system

•360 Amp

•Collision Guard - Torch Protection Software

•(2) - 24 X 24 in. (0.6 X 0.6 m) Precision Machined Tooling Plates

Recommended Options

•Power Ream™ (Torch Reaming Station with Sprayer/Clipper)

•Fume Exhaust Environmental System

•Password Protection Software

•TorchMate 2 – Automatic Tool Center Point Adjustment Software

•PCMCIA 64MB Memory Card

•AccuTrak® Payoff Kit

•Simple Fixturing Required

Order

TECHNICAL SPECIFICATIONS

Product

Name

eCell

Product

Number

Input

Power

230/460/575/3/60

(20KVA Max)

Power Source

Current/Voltage/

Duty Cycle

Power Wave 355M

350A/34V/60%

(300A/32V/100%)

Feeder/Torch

360 Amp A/C Torch

(100% CO2)

Robot

ArcMate

100iBe (6 axis)

Dimensions

H x W x D

inches (mm)

80x90x60

(2032x2286x1524)

Net

Weight

lbs. (kg)

2200

(998)

Publication E10.120 | 8/07 |

www.lincolnelectric.com