IM839 specifications

Lincoln Electric IM839 is a state-of-the-art inverter-based multi-process welding machine that has garnered significant attention in the welding industry due to its advanced features and capabilities. Designed to meet the demands of professional welders, the IM839 is suitable for a variety of applications, including MIG, TIG, and Stick welding.One of the standout features of the IM839 is its versatility. It supports both gas and gasless welding processes, allowing users to select the best method for their specific projects. The machine operates on a wide input voltage range, making it ideal for use in different environments, from small workshops to large industrial settings. This flexibility ensures that the IM839 can be utilized for both light and heavy-duty welding tasks.

The IM839 also employs advanced inverter technology, which enhances the arc stability and reduces overall power consumption. This technology provides a more efficient performance compared to traditional welding machines, allowing for a smoother welding experience and improved bead appearance. The inverter design also contributes to its lightweight and compact structure, making it highly portable and easy to transport.

Equipped with multiple welding modes, the IM839 offers users the ability to adjust settings based on their specific requirements. The intuitive user interface allows for quick parameter adjustments, enabling welders to switch between processes seamlessly. Additionally, the machine features advanced weld control technology, which ensures consistent performance across different materials and thicknesses.

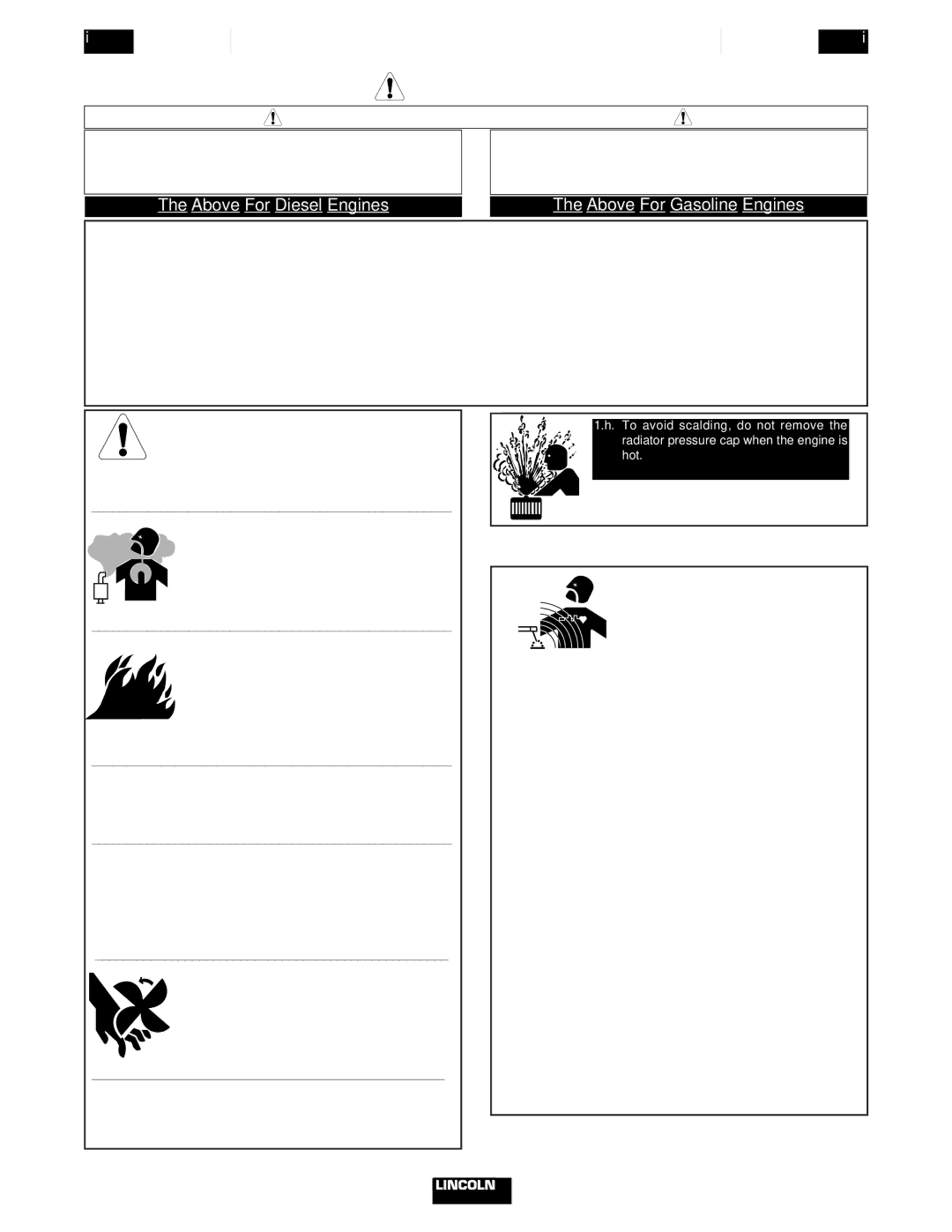

Safety is another priority with the IM839. The machine includes built-in thermal overload protection, which prevents damage during extended use or when operated beyond its optimal capacity. It also features a robust design to withstand the rigors of harsh working environments, providing both durability and reliability.

The IM839 is compatible with a range of accessories, enhancing its functionality further. With options for spool guns and TIG torches, users can expand their capabilities, making this machine an excellent investment for anyone serious about welding. The combination of advanced technologies, exceptional versatility, and user-friendly functionality makes the Lincoln Electric IM839 a leading choice for welders seeking high-performance solutions in their welding operations.