CORED WIRE

Innershield® NR-233

Self-Shielded Flux-Cored Wire

(AWS A5.20-95: E71T-8)

Advantage Lincoln

User Friendly

•For the engineer: meets the stringent codes and standards for Charpy

•For the plant superintendent: higher deposition rates mean faster building erection, quicker launch of the barge, or more throughput in fabrication. In short: less cost and more profit.

•For the welder: a more forgiving arc with greater penetration makes it easier to pass qualification tests, and makes for bet ter quality welds in production — and the welds look great.

•

Typical Applications

•Vertical up fillet and groove welds

•Overhead fillet and groove welds

•Seismic structural steel erection

•General structural steel erection

•Barge fabrication

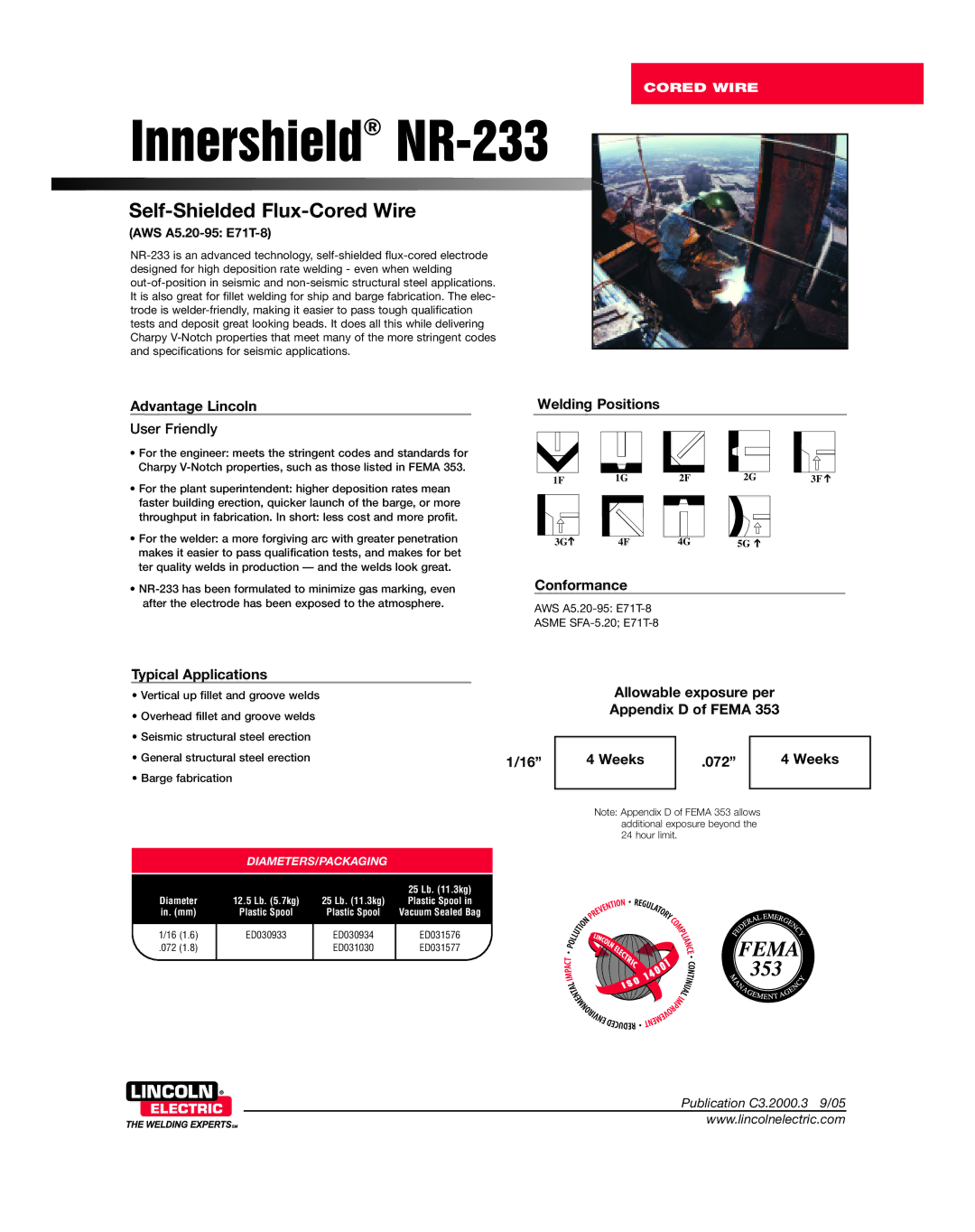

Welding Positions |

|

|

| |

1F | 1G | 2F | 2G | 3F➔ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3G➔ | 4F |

|

|

|

|

|

|

4G |

| 5G | ➔ | ||||

Conformance

AWS

ASME

Allowable exposure per

Appendix D of FEMA 353

1/16” | 4 Weeks | .072” | 4 Weeks |

|

|

|

|

Note: Appendix D of FEMA 353 allows additional exposure beyond the 24 hour limit.

DIAMETERS/PACKAGING

Diameter in. (mm)

1/16 (1.6)

.072 (1.8)

12.5Lb. (5.7kg) Plastic Spool

ED030933

25 Lb. (11.3kg)

Plastic Spool

ED030934

ED031030

25 Lb. (11.3kg)

Plastic Spool in

Vacuum Sealed Bag

ED031576

ED031577

Publication C3.2000.3 9/05

www.lincolnelectric.com