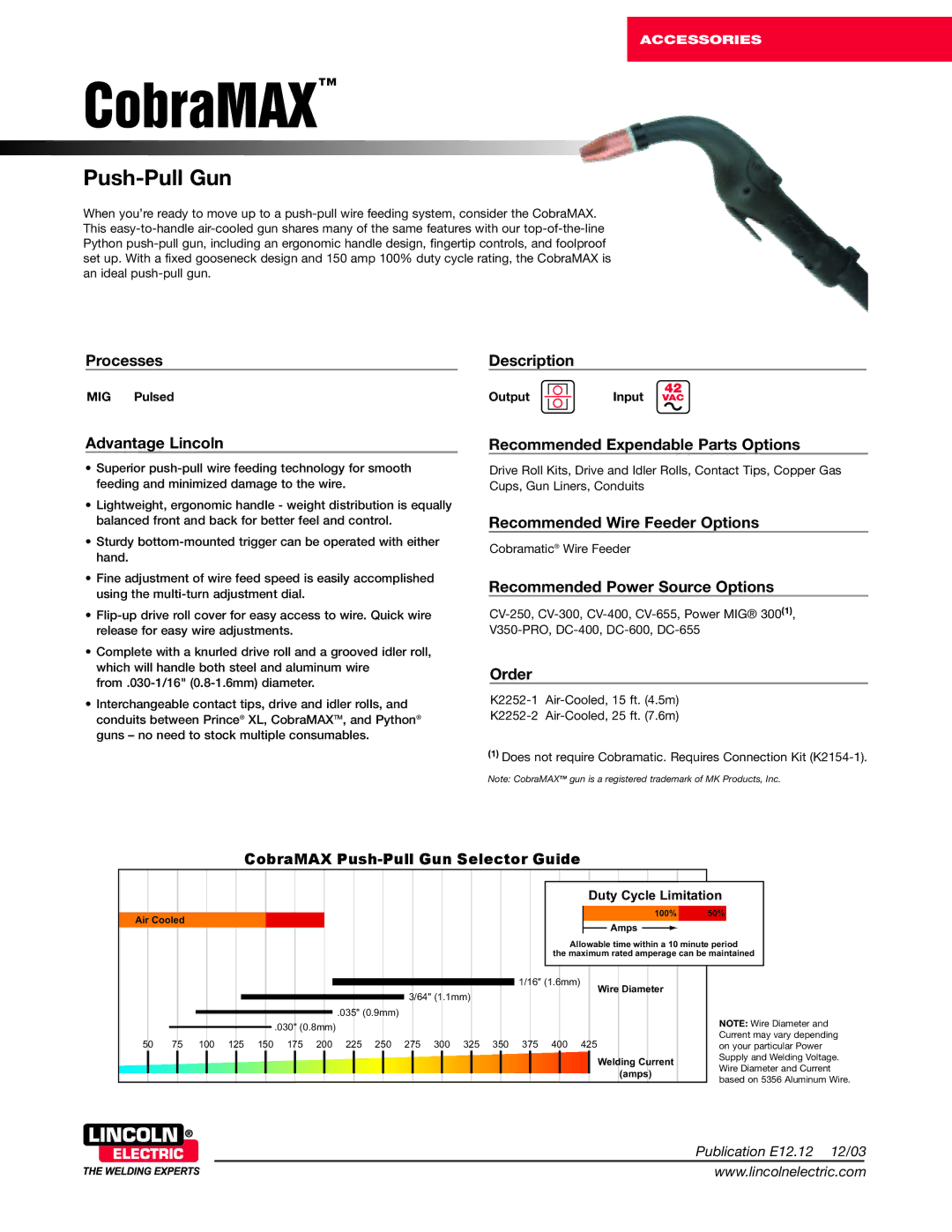

Push-Pull Gun specifications

The Lincoln Electric Push-Pull Gun stands as a testament to advanced welding technology, specifically designed to cater to the ever-increasing demands of welding professionals. Engineered for precision, versatility, and ease of use, this gun is an essential tool for aluminum and other soft metal applications where wire feeding can be a challenge.At the heart of the Push-Pull Gun is its innovative design, which integrates both push and pull forces to deliver a smooth and consistent wire feed. This dual mechanism minimizes wire friction and extends the soft aluminum wire's feeding capability, making it perfect for overhead and vertical welding applications. Operators can expect a steady and reliable feed that ensures high-quality welds, reducing the risk of wire jams and spatter.

One of the standout features of the Lincoln Electric Push-Pull Gun is its ergonomic design. The gun is crafted with a lightweight structure that promotes comfort during prolonged use. Its balanced weight distribution reduces user fatigue, allowing welders to maintain precision in their work without compromise. The gun's handle is designed with customer feedback in mind, featuring an easy-grip design that further enhances comfort and control.

The Push-Pull Gun also utilizes advanced technologies, such as its efficient cooling system, which helps to maintain optimal performance during extended welding sessions. The gun can withstand high temperatures without compromising integrity, providing peace of mind to users who demand reliability under pressure.

Moreover, the Lincoln Electric Push-Pull Gun is compatible with a range of Lincoln Electric welding machines, making it a versatile addition to any weld shop. Its easy connectivity ensures seamless integration into existing setups, providing users with flexibility and adaptability across various applications.

The intuitive design includes quick-change nozzle systems, allowing users to switch between different nozzle sizes and types without extensive downtime. This feature is particularly beneficial in high-production environments where efficiency is key.

Overall, the Lincoln Electric Push-Pull Gun epitomizes the fusion of innovative engineering and practical functionality. Its advanced wire feeding capabilities, ergonomic design, and compatibility with various welding machines make it a standout choice for professionals seeking to elevate their welding performance. With this tool in hand, welders gain the confidence and capability to tackle even the most challenging projects with ease and precision.