TECHNOLOGY

P O W E R E L E C T R O N I C S T E C H N O L O G Y

Inverters and Choppers

Technology creates change. The ability to evolve along with change is what distinguishes a successful product from the rest.

Power source design is almost entirely devoted to reliability. Fast power conversion is important to obtaining a smooth welding output, but we also know that speed is inconsequential without reliability. No matter how fast your machine operates, if it is not durable, then it is not usable for welding. And if it is not welding, you are not meeting your production goals and making a living.

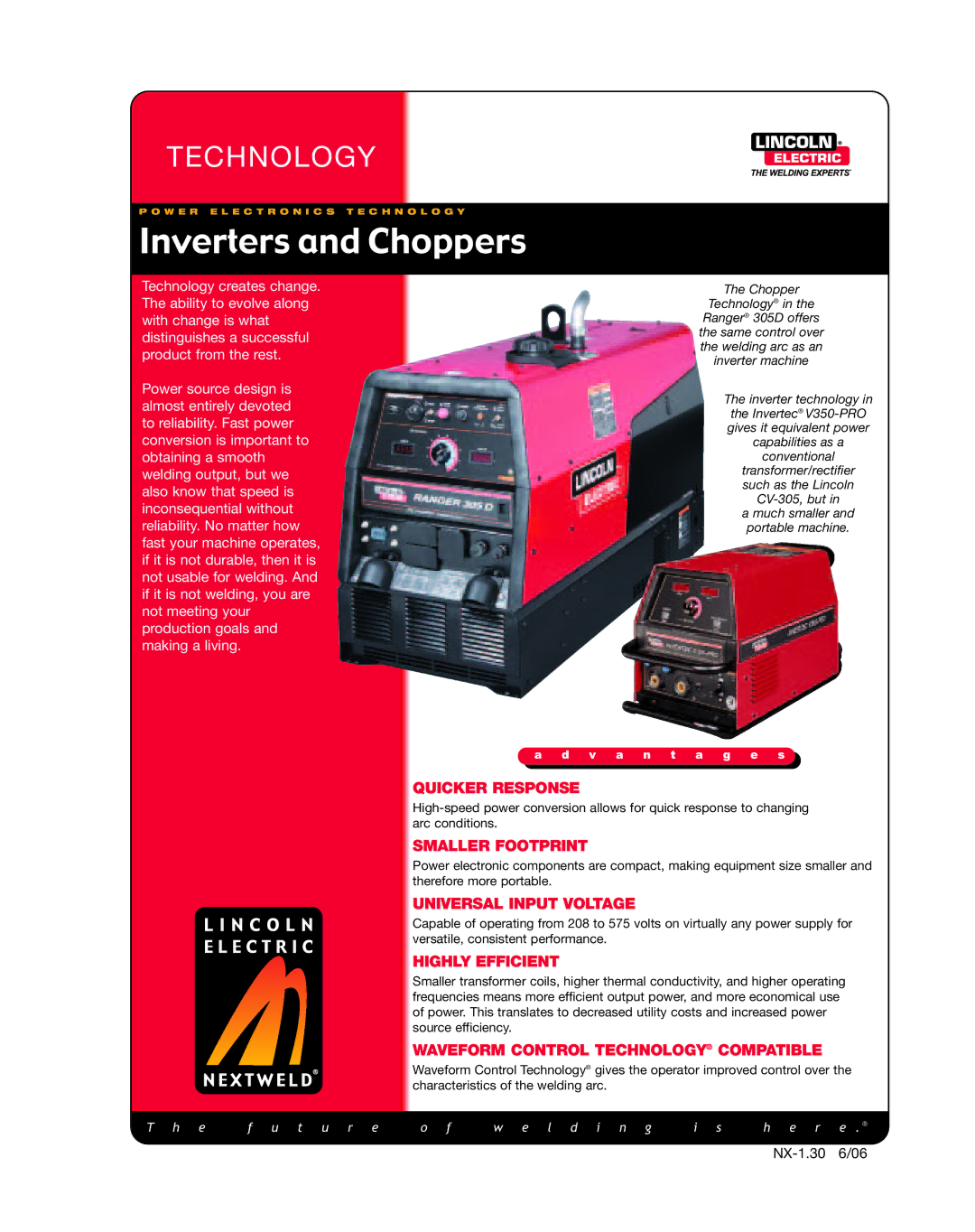

The Chopper

Technology® in the Ranger® 305D offers the same control over the welding arc as an inverter machine

The inverter technology in the Invertec®

a much smaller and portable machine.

QUICKER RESPONSE

SMALLER FOOTPRINT

Power electronic components are compact, making equipment size smaller and therefore more portable.

UNIVERSAL INPUT VOLTAGE

Capable of operating from 208 to 575 volts on virtually any power supply for versatile, consistent performance.

HIGHLY EFFICIENT

Smaller transformer coils, higher thermal conductivity, and higher operating frequencies means more efficient output power, and more economical use of power. This translates to decreased utility costs and increased power source efficiency.

WAVEFORM CONTROL TECHNOLOGY® COMPATIBLE

Waveform Control Technology® gives the operator improved control over the characteristics of the welding arc.

T h e | f u t u r e | o f | w e l d i n g | i s | h e r e . ® |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|