CB--CW 987 - 2067 specifications

The Lochinvar CB--CW 987 - 2067 represents a significant advancement in the world of commercial water heating solutions. Designed for a range of applications including large facilities and industrial operations, this unit combines efficiency, reliability, and sophisticated technology.One of the standout features of the Lochinvar CB--CW model is its impressive thermal efficiency rating. With a minimum efficiency of 95%, it minimizes energy consumption while maximizing output. This high-efficiency design not only reduces operating costs but also contributes to an environment-friendly footprint, supporting sustainability goals.

The CB--CW series incorporates advanced condensing technology, allowing it to recover and utilize heat that would otherwise be lost. By capturing flue gases and converting them into usable energy, the system achieves higher performance and lower emissions. This state-of-the-art design is particularly beneficial in meeting the stringent regulations imposed on commercial heating systems.

Another significant characteristic is its compact footprint, which is particularly advantageous in facilities with limited space. The CB--CW series can be installed in various configurations, ensuring flexibility in integration with existing systems. This adaptability streamlines installation processes and minimizes the disruption to operations.

The Lochinvar CB--CW 987 - 2067 is also designed for ease of maintenance. Its user-friendly interface and integrated diagnostics provide operators with real-time information and alerts. This proactive approach helps to reduce downtime and facilitates prompt service, ensuring that the unit operates at optimal performance levels consistently.

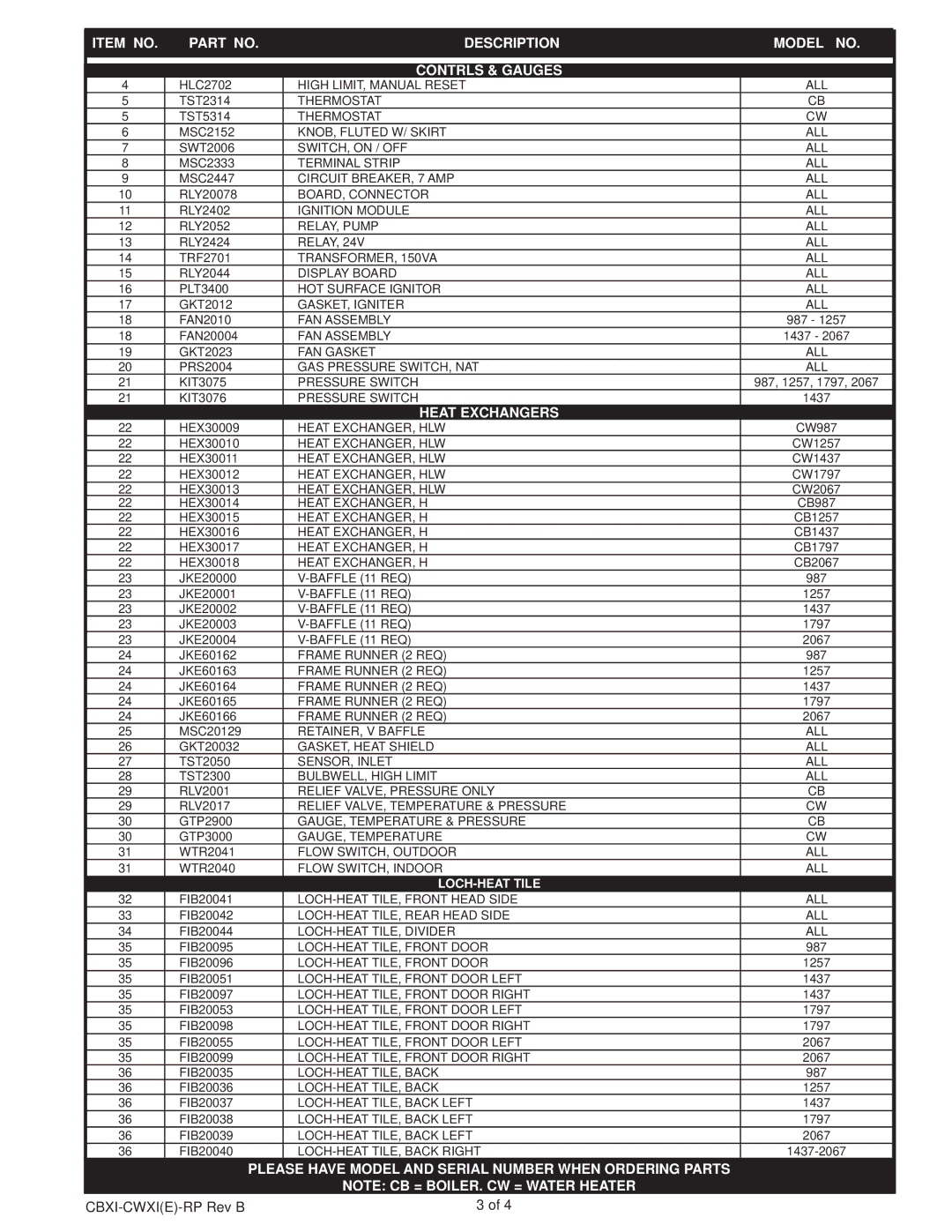

The system features a robust build quality, equipped with stainless steel heat exchangers that enhance durability and corrosion resistance. This longevity ensures that the unit can handle the demands of various applications over time without sacrificing performance.

In addition to its engineering prowess, the Lochinvar CB--CW model is equipped with smart technology. Features such as remote access and advanced control systems allow users to monitor and adjust settings from anywhere, providing convenience and efficiencies in operation.

Overall, the Lochinvar CB--CW 987 - 2067 stands out as a leader in commercial water heating technology. With its high efficiency, advanced condensing capabilities, compact design, and focus on maintenance, it meets the needs of modern facilities seeking reliable and cost-effective heating solutions.