IB/IW 2000, IB/IW 1700, IB/IW 1500 specifications

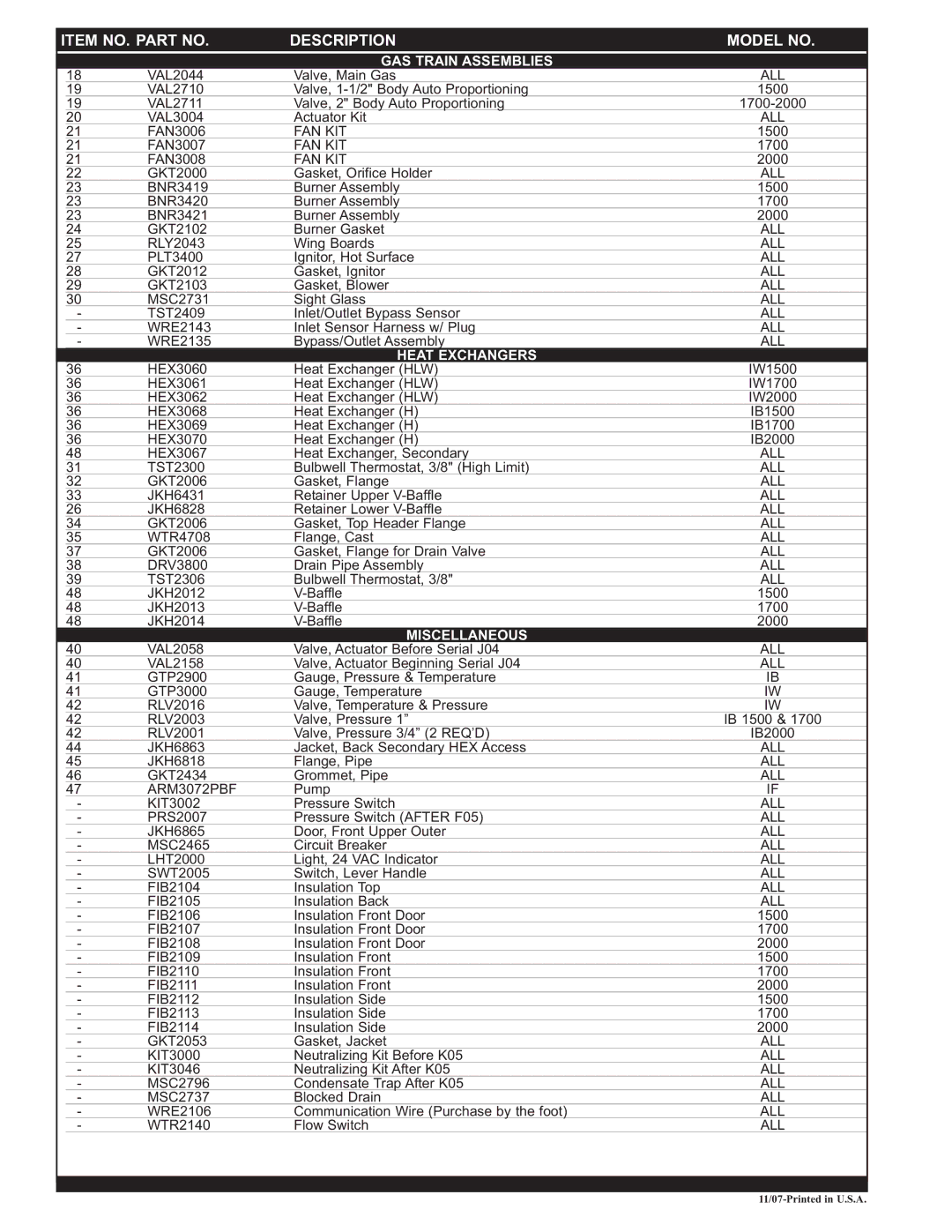

Lochinvar has been a renowned name in the heating industry, providing advanced solutions in boiler technology. Among their impressive lineup are the Lochinvar IB/IW 1700, IB/IW 2000, and IB/IW 1500 models, each designed to deliver exceptional performance and efficiency for various applications.The Lochinvar IB/IW series is notable for its innovative design and high-efficiency operation. The IB/IW 1700 model boasts a remarkable input capacity of 1,700,000 BTU/hr, making it suitable for larger residential or commercial settings. Its compact design allows for easy installation and versatility in tight spaces. The unit incorporates a durable stainless-steel heat exchanger that enhances longevity while providing superior heat transfer efficiency.

Similarly, the Lochinvar IB/IW 2000 stands out with an even higher input capacity of 2,000,000 BTU/hr. This model is ideal for extensive heating demands, ensuring that large buildings and facilities maintain optimal warmth during colder months. Equipped with advanced modulating technology, the IB/IW 2000 adjusts its output according to the heating requirements, thus ensuring energy savings and improved comfort levels.

The IB/IW 1500 model, catering to slightly lower input needs at 1,500,000 BTU/hr, combines efficiency with user-friendly features. Like its counterparts, it employs a robust stainless-steel heat exchanger, which is resistant to corrosion and ensures reliable operation over time. The IB/IW 1500 also features smart control systems that enable users to monitor and adjust settings conveniently, enhancing operational efficiency.

All models in the Lochinvar IB/IW range are constructed with a focus on safety, featuring built-in safety mechanisms that prevent operational issues. This includes pressure relief valves and advanced combustion control systems that not only optimize performance but also minimize emissions.

The entire IB/IW series is designed with user-friendly interfaces, allowing easy access to crucial information and settings. Their compact footprint and modular design make them suitable for various setups, whether as stand-alone units or as part of a broader heating solution.

In summary, the Lochinvar IB/IW 1700, IB/IW 2000, and IB/IW 1500 models showcase advanced engineering and technology. With their emphasis on efficiency, durability, and user-friendliness, these boilers stand as an excellent choice for anyone seeking reliable heating solutions for commercial or large residential applications.