KB 399 thru 800 specifications

The Lochinvar KB series, ranging from models KB 399 to KB 800, represents a groundbreaking line of commercial condensing boilers designed to meet the heating demands of various commercial applications. These units showcase Lochinvar’s commitment to efficiency, innovation, and durability, making them a preferred choice for engineers and contractors alike.One of the most compelling features of the KB series is its impressive thermal efficiency, often exceeding 95%. This is largely attributed to its advanced condensing technology, which extracts heat from flue gases that would otherwise be lost in traditional boilers. The stainless-steel heat exchanger enhances this efficiency by resisting corrosion and ensuring a long lifespan for the unit.

The KB series also incorporates a powerful blowers system, which provides modulating combustion. This feature allows the boiler to adjust the burner output according to the heating demand, resulting in optimal fuel usage and minimized emissions. This flexibility not only enhances efficiency but also contributes to a lower environmental footprint, complying with stringent emissions regulations.

Another notable aspect of the KB series is the built-in control system. The advanced touchscreen display allows for easy programming and monitoring, providing real-time performance data and system diagnostics. This user-friendly interface facilitates maintenance and troubleshooting, thus reducing downtime and operational costs.

In terms of installation, the KB models are designed with a compact footprint and lightweight construction, making them easier to integrate into existing boiler rooms or new installations. The series offers versatility in venting options, including direct vent and indoor models, catering to diverse building configurations and compliance needs.

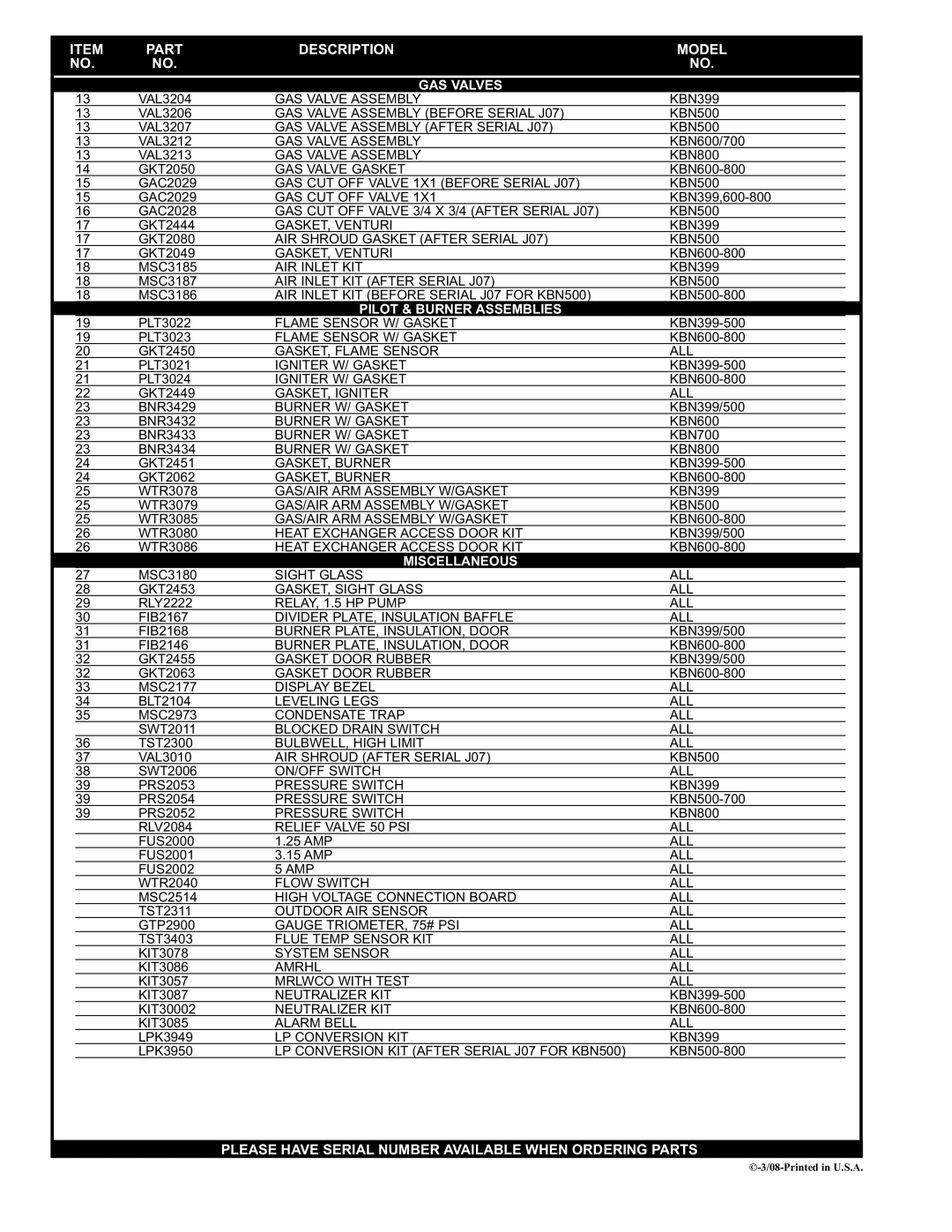

Safety is also a paramount concern in the KB series design. Each unit comes equipped with multiple safety features, including a high limit temperature control, a flame safeguard system, and water pressure monitoring. These safety measures ensure that the boiler operates reliably and protects the integrity of the heating system.

In conclusion, the Lochinvar KB series 399 to 800 exemplifies advanced engineering in commercial heating solutions. With high efficiency, flexible operation, intuitive controls, ease of installation, and robust safety features, these boilers provide a reliable and economical solution for diverse commercial heating applications. Whether for schools, hospitals, or industrial facilities, Lochinvar KB boilers are poised to deliver exceptional performance and peace of mind for years to come.