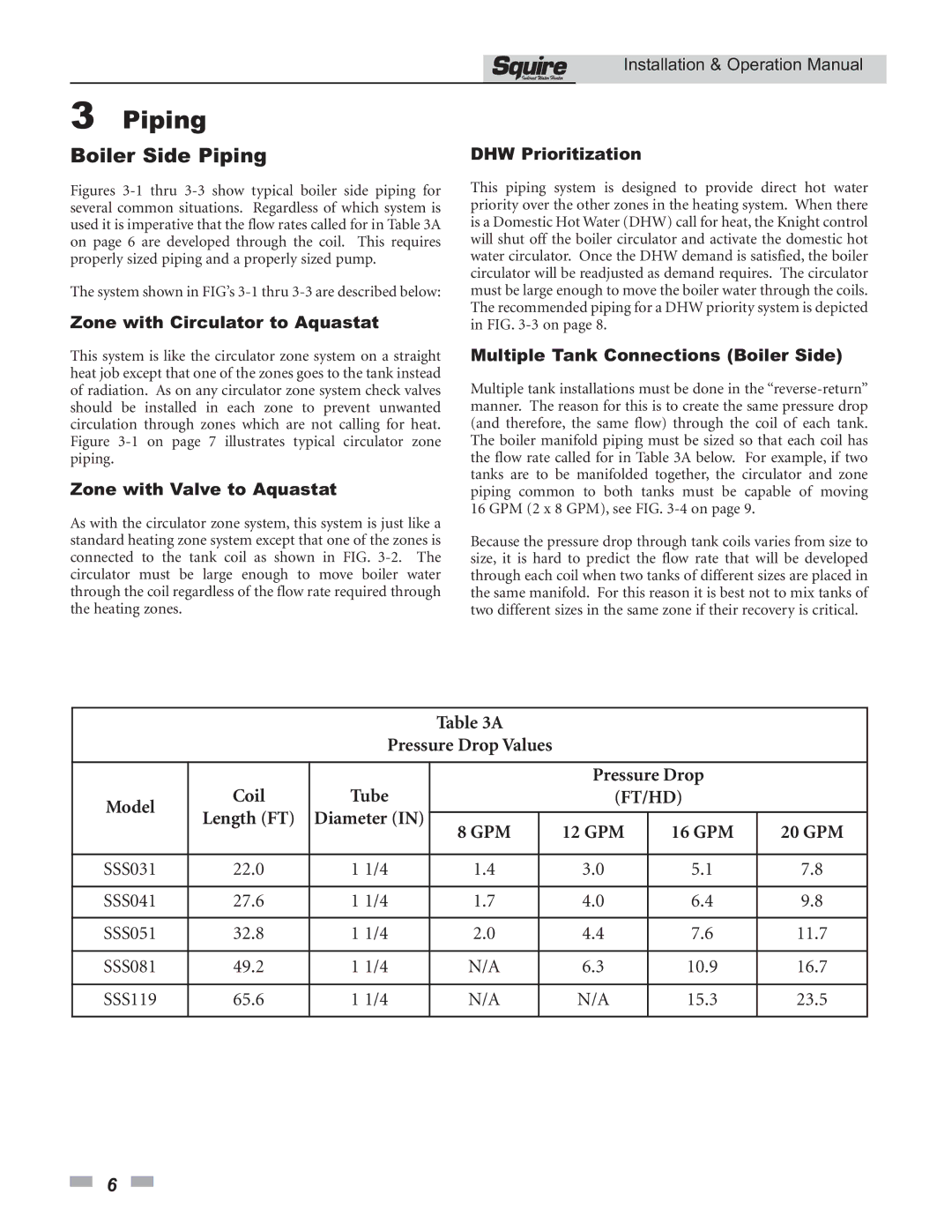

SSS119, SSS031, SSS041, SSS051, SSS081 specifications

Lochinvar is a well-regarded name in the heating and water heating industry, renowned for its innovative and efficient solutions. Among their notable products are the SSS031, SSS041, SSS119, SSS081, and SSS051, a series of high-efficiency condensing boilers designed for residential and commercial use.The Lochinvar SSS series, which includes models like SSS031 through SSS119, showcases advanced technologies aimed at optimizing energy efficiency and performance. One of the standout features of these models is their stainless steel construction, which enhances durability and resistance to corrosion. This material choice not only extends the lifespan of the units but also contributes to their energy efficiency by ensuring consistent heat transfer.

In addition to stainless steel, Lochinvar incorporates cutting-edge condensing technology in the SSS series. This design allows the boilers to extract additional heat from the exhaust gases, making use of latent heat that would otherwise be lost in traditional models. As a result, the SSS series achieves impressive Annual Fuel Utilization Efficiency (AFUE) ratings, often exceeding 90%. This high efficiency not only reduces energy consumption but also lowers operating costs, making these boilers a smart investment for both residential and commercial applications.

Another key characteristic of the Lochinvar SSS series is its user-friendly control system. Equipped with a touchscreen interface, operators can easily monitor and adjust settings for optimal performance and comfort. The integration of smart technologies and connectivity features allows for remote monitoring and control, enhancing the user experience and enabling proactive maintenance.

Furthermore, safety is a paramount concern in the design of the SSS models. They are equipped with multiple safety features including modulating burners and a low-water cutoff system, which ensures safe operation under various conditions.

The SSS031, SSS041, SSS119, SSS081, and SSS051 models cater to a range of heating demands, from smaller homes to larger commercial spaces. Each model varies in capacity, allowing users to select the appropriate unit based on their specific heating requirements. This flexibility, combined with the series' robust features and efficiencies, underscores Lochinvar’s commitment to providing reliable and sustainable heating solutions that meet the evolving needs of modern energy consumers.