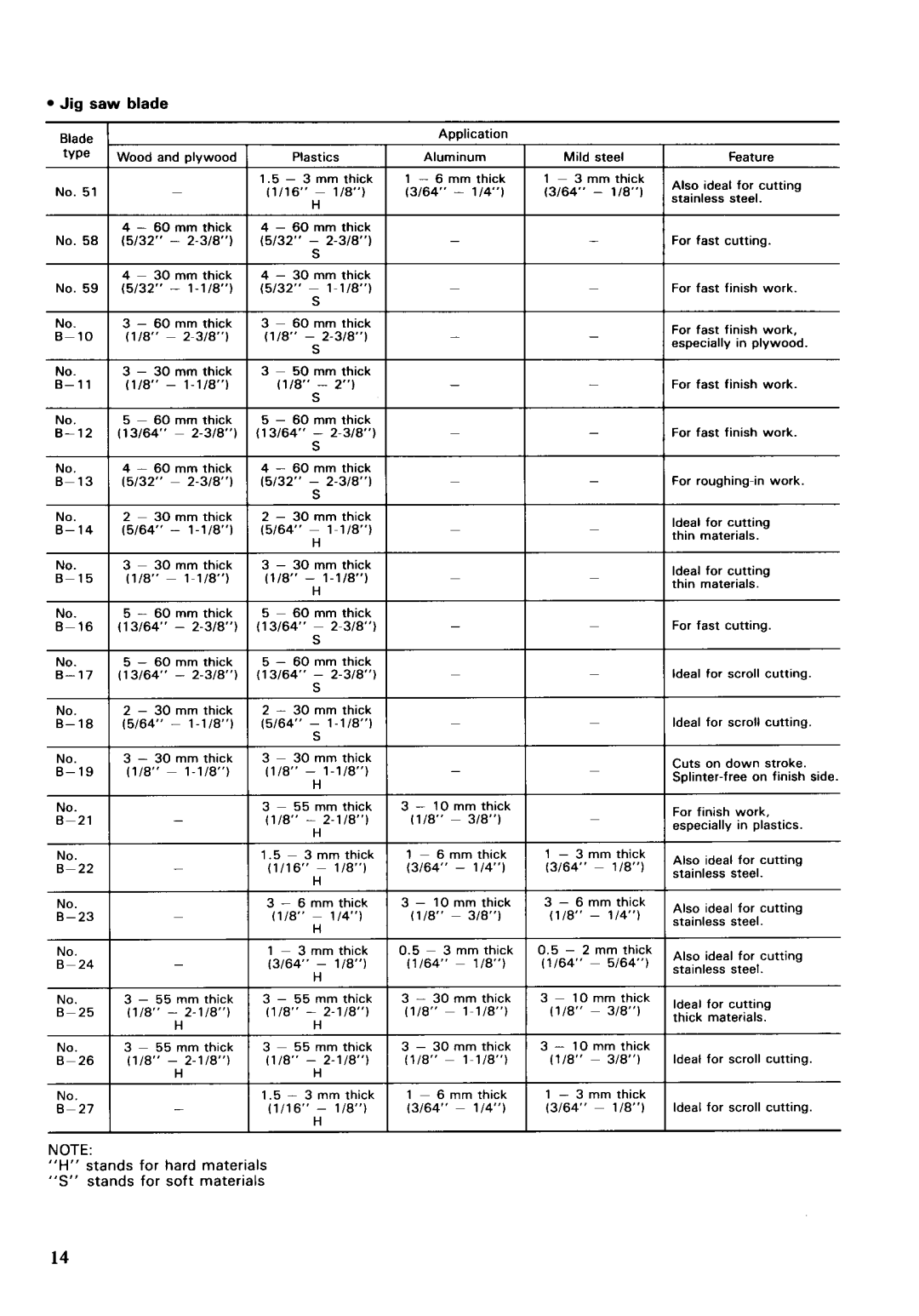

Jig saw blade

Jig saw blade

| I |

| Plastics | |

No. 51 |

| 1.5 - 3 mm thick | ||

| 11/16’ - 1/8”) | |||

|

|

| H | |

|

| 4 - 60 mm thick | 4 - 60 mm thick | |

|

|

| 15/32’’ - | |

|

| 4 - 30 mm thick | 4 - 30 mm thick | |

|

|

| 15/32’’ - | |

|

|

| 3 - 60 mm thick | |

| I |

| ll/8” - | |

|

| S | ||

No. | 3 - 30 mm thick |

| ||

l1/8” - |

| |||

| I | 113/64” - |

| |

No. | 4 - 60 mm thick | 4 - 60 mm thick | ||

15/32” - | 15/32” - | |||

No. | I | 2 - 30 mm thick | 2 - 30 mm thick | |

15/64‘’ - | 15/64‘’ U | |||

|

|

| - | |

| 11/8” - l - l/8”) | 3 - 30 mm thick | ||

| 11/8‘ - | |||

|

|

| H | |

No. |

| 5 - 60 mm thick | 5 - 60 mm thick | |

I l13/64“ - | (13/64“ - | |||

9 | ||||

|

|

| ||

|

| ( 13/64” - | 5 - 60 mm thick | |

|

| (13/64” - | ||

Yq z15/64”F K-

15/64” - 1 - 1/8”)

No. | I | 3 - 30 mm thick | 3 - 30 mm thick | ||

11/8“ | - | l - l / 8 ” ) | 11/8” - | ||

|

| ||||

|

|

|

|

| 3 - 55 mm thick |

| I |

|

|

| 11/8” - |

|

|

|

| H | |

No. |

|

|

| 1.5 - 3 mm thick | |

|

|

| 11/16’’ - 1/8”) | ||

|

|

| H | ||

|

|

|

|

| 3 - 6 mm thick |

|

|

|

|

| (118’’ - 1/4”) |

|

|

|

|

| 1 - 3 mm thick |

|

|

|

|

| 13/64’ - 118”) |

|

|

|

|

| H |

|

| 3 - 55 mm thick | 3 - 55 mm thick | ||

|

|

|

|

| (1/8” - |

|

|

|

|

| H |

No. |

| 3 - 55 mm thick | 3 - 55 mm thick | ||

I 11/8” - | (1/8“ - | ||||

H | |||||

No. | 1 |

|

|

| 1.5 - 3 mm thick |

| - |

| 11/16’’ - 118”) | ||

|

| U | |||

NOTE:

”H” stands for hard materials ”S” stands for s o f t materials

I

I

I

I

I

I

I

II

Application

Aluminum

1- 6 mm thick

13/64” - 1/4‘l

-

-

-

3 - 10 mm thick 1118‘’ - 318”)

1 - 6 mm thick (3164‘’ - 114“)

3 - 10 mm thick (1/8” - 3/8”l

0.5 - 3 mm thick

11/64“ - 1/8”)

3- 30 mm thick

11/8” - l - l / 8 ” )

3- 30 mm thick

1118’’ -

1 - 6 mm thick

13/64” - 114”)

Mild steel

1 - 3 mm thick

13/64’’ - 1/8”l

-

I -

I

I

I

I

1- 3 mm thick

13/64” - 1/8”)

3 - 6 mm thick

( 1/8” - 1/4”)

I 0.5 - 2 mm thick 11/64” - 5/64”)

3 - 10 mm thick 11/8” - 3/8”)

3 - 10 mm thick

11/8” - 3/8”)

1- 3 mm thick 13/64” - 118”)

Feature

Also ideal for cutting stainless steel.

For fast cutting.

For fast finish work.

For fast finish work, especially in plywood

For fast finish work.

For fast finish work.

For

Ideal for cutting thin materials.

Ideal for cutting thin materials.

For fast cutting.

Ideal for scroll cutting.

Ideal for scroll cutting

Cuts on down stroke.

For finish work, especially in plastics

Also ideal for cutting stainless steel.

Also ideal for cutting stainless steel.

Also ideal for cutting stainless steel.

Ideal for cutting thick materials.

Ideal for scroll cutting

Ideal for scroll cutting.

14