NOTE :

0 Use the proper bit for the head of the screw that you wish to use.

0 Make sure that the driver bit is inserted straight in the screw head, or the screw and/or bit may be damaged.

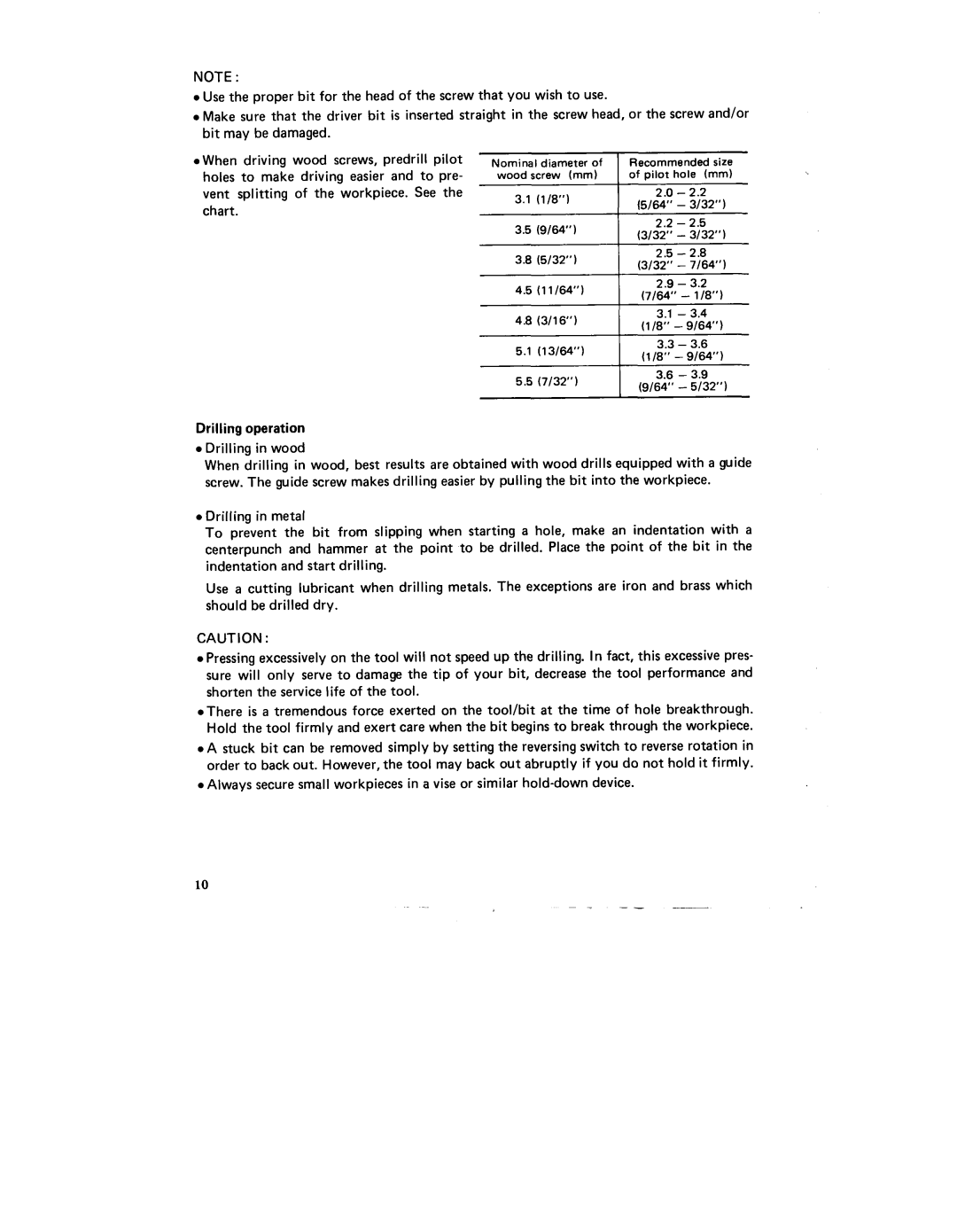

0 When driving wood screws, predrill Pilot holes to make driving easier and to pre- vent splitting of the workpiece. See the chart.

Nominal diameter of I Recommended size

wood screw (mm) of pilot hole (mm)

3.1 (1/8")2.0

2.2

3.5(9/64") (3/32"

3.8(5/32")2.5

4.5 (1 1 /64") | 2.9 - 3.2 |

(7/64" |

3.1- 3.4

4.8(3/16') (118''-9/64')

3.6- 3.9

5.5(7/32") (9/64" -5/32")

Drilling operation

0 Drilling in wood

When drilling in wood, best results are obtained with wood drills equipped with a guide screw. The guide screw makes drilling easier by pulling the bit into the workpiece.

0 Drilling in metal

To prevent the bit from slipping when starting a hole, make an indentation with a centerpunch and hammer at the point to be drilled. Place the point of the bit in the indentation and start drilling.

Use a cutting lubricant when drilling metals. The exceptions are iron and brass which should be drilled dry.

CAUTION :

0 Pressing excessively on the tool will not speed up the drilling. In fact, this excessive pres- sure will only serve to damage the tip of your bit, decrease the tool performance and shorten the service life of the tool.

.There is a tremendous force exerted on the tool/bit at the time of hole breakthrough. Hold the tool firmly and exert care when the bit begins to break through the workpiece.

0 A stuck bit can be removed simply by setting the reversing switch to reverse rotation in order to back out. However, the tool may back out abruptly if you d o not hold it firmly.

*Always secure small workpieces in a vise or similar

10