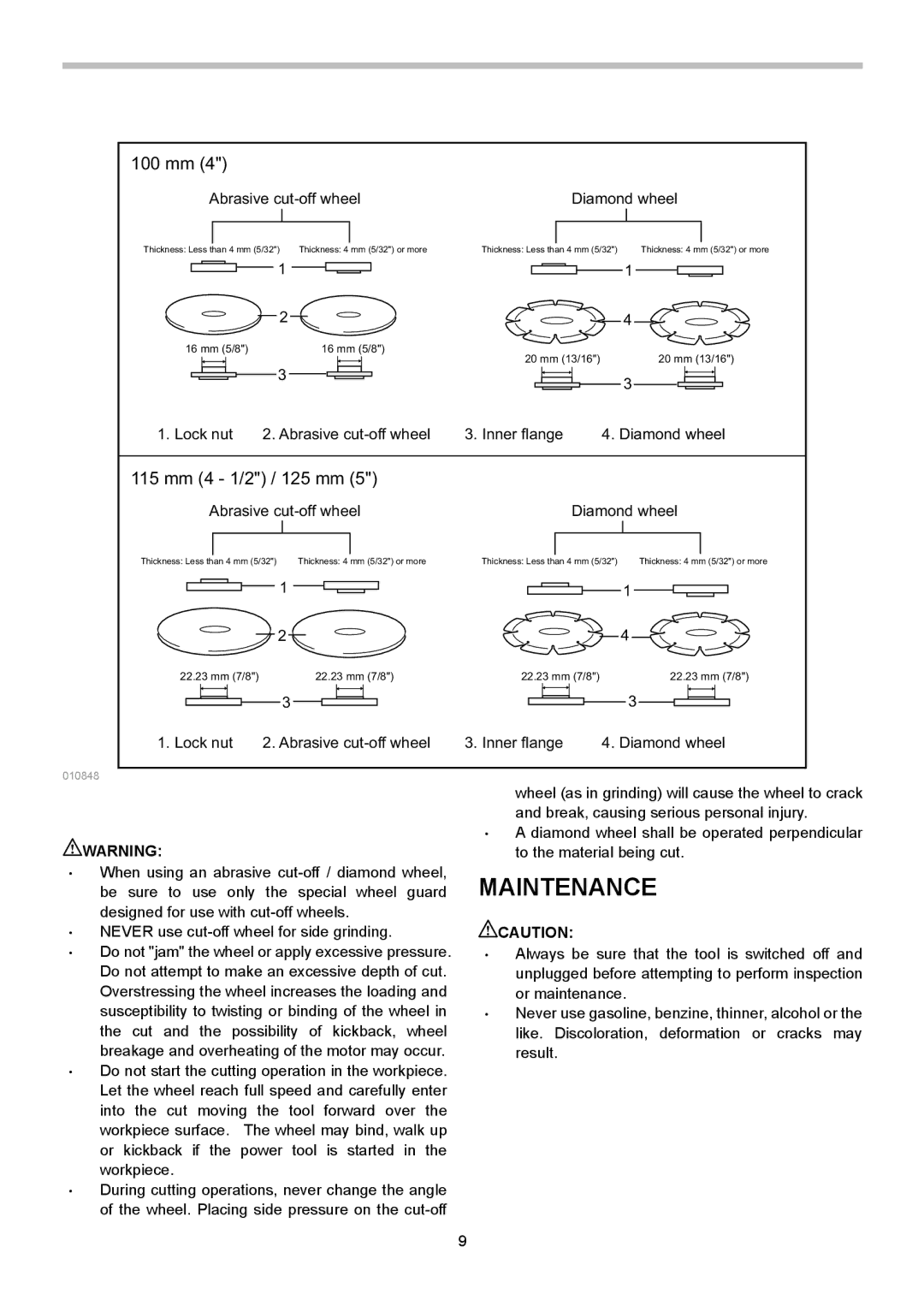

100 mm (4")

Abrasive |

| Diamond wheel | |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Thickness: Less than 4 mm (5/32") Thickness: 4 mm (5/32") or more | Thickness: Less than 4 mm (5/32") Thickness: 4 mm (5/32") or more | ||||||

1

![]() 2

2 ![]()

![]()

![]()

1

4

16 mm (5/8") |

|

| 16 mm (5/8") |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

| 3 |

|

|

|

|

|

|

| 20 mm (13/16") |

| 3 | 20 mm (13/16") | |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

1. Lock nut | 2. Abrasive | 3. Inner flange | 4. Diamond wheel | ||||||||||||||||||||||||||

115 mm (4 - 1/2") / 125 mm (5")

Abrasive |

| Diamond wheel | |||

Thickness: Less than 4 mm (5/32") | Thickness: 4 mm (5/32") or more | Thickness: Less than 4 mm (5/32") | Thickness: 4 mm (5/32") or more | ||

|

| 1 |

|

| 1 |

|

| 2 |

|

| 4 |

22.23 mm (7/8") |

| 22.23 mm (7/8") | 22.23 mm (7/8") | 22.23 mm (7/8") | |

|

| 3 |

|

| 3 |

1. Lock nut | 2. Abrasive | 3. Inner flange | 4. Diamond wheel | ||

010848

![]() WARNING:

WARNING:

•When using an abrasive

•NEVER use

•Do not "jam" the wheel or apply excessive pressure. Do not attempt to make an excessive depth of cut. Overstressing the wheel increases the loading and susceptibility to twisting or binding of the wheel in the cut and the possibility of kickback, wheel breakage and overheating of the motor may occur.

•Do not start the cutting operation in the workpiece. Let the wheel reach full speed and carefully enter into the cut moving the tool forward over the workpiece surface. The wheel may bind, walk up or kickback if the power tool is started in the workpiece.

•During cutting operations, never change the angle of the wheel. Placing side pressure on the

wheel (as in grinding) will cause the wheel to crack and break, causing serious personal injury.

•A diamond wheel shall be operated perpendicular to the material being cut.

MAINTENANCE

![]() CAUTION:

CAUTION:

•Always be sure that the tool is switched off and unplugged before attempting to perform inspection or maintenance.

•Never use gasoline, benzine, thinner, alcohol or the like. Discoloration, deformation or cracks may result.

9