Thank you

for deciding to choose a Makita | drying, | Used in the proper manner |

heat gun. This tool can be used | etc. All Makita tools are manufac- | (please read the information on |

for completing a wide range of | tured to the highest standards and | p. 8), this heat gun will give you |

jobs safely and reliably, such as | undergo a strict process of quality | lasting satisfaction. |

soldering, welding PVC, shaping, | control. |

|

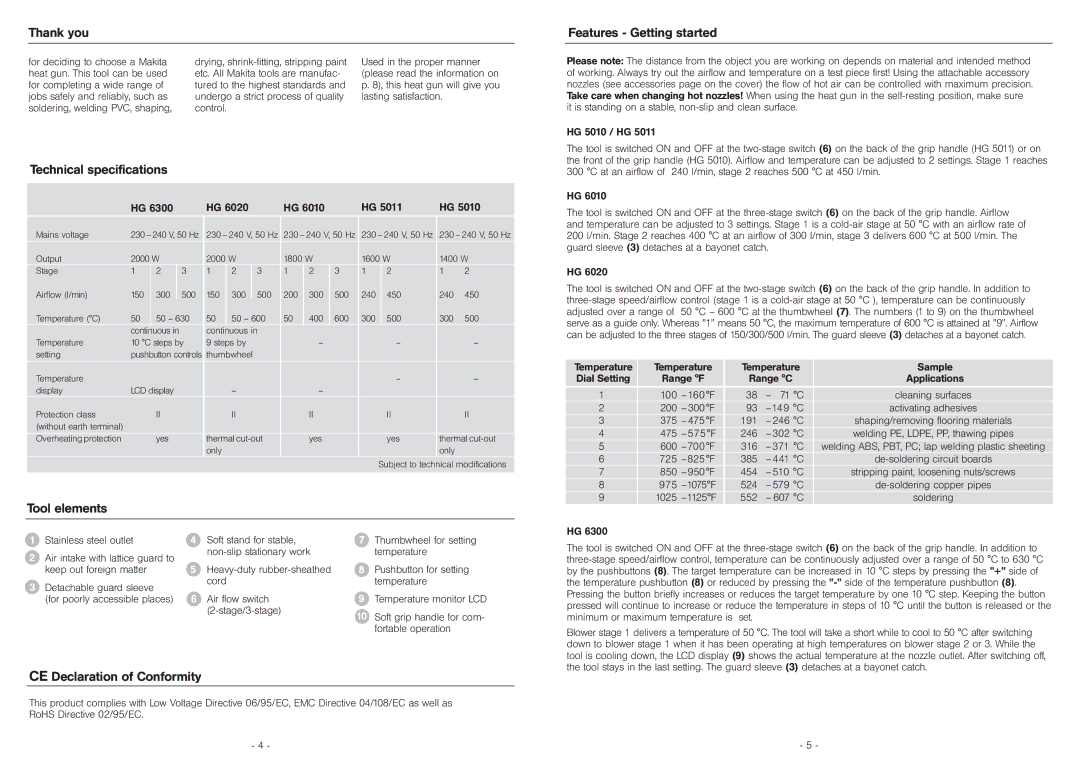

Technical specifications

| HG 6300 |

| HG 6020 |

| HG 6010 |

| HG 5011 | HG 5010 | |||||

Mains voltage | 230 – 240 V, 50 Hz | 230 – 240 V, 50 Hz | 230 – 240 V, 50 Hz | 230 – 240 V, 50 Hz | 230 – 240 V, 50 Hz | ||||||||

Output | 2000 W |

| 2000 W |

| 1800 W |

| 1600 W | 1400 W | |||||

Stage | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 1 | 2 |

Airflow (l/min) | 150 | 300 | 500 | 150 | 300 | 500 | 200 | 300 | 500 | 240 | 450 | 240 | 450 |

Temperature (°C) | 50 | 50 – 630 | 50 | 50 – 600 | 50 | 400 | 600 | 300 | 500 | 300 | 500 | ||

| continuous in |

| continuous in |

|

|

|

|

|

|

| |||

Temperature | 10 °C steps by | 9 steps by |

|

| – |

|

| – |

| – | |||

setting | pushbutton controls | thumbwheel |

|

|

|

|

|

|

|

| |||

Temperature |

|

|

|

|

|

|

|

|

|

| – |

| – |

display | LCD display |

|

| – |

|

| – |

|

|

|

|

| |

Protection class |

| II |

|

| II |

|

| II |

|

| II |

| II |

(without earth terminal) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Overheating protection |

| yes |

| thermal |

| yes |

|

| yes | thermal | |||

|

|

|

| only |

|

|

|

|

|

|

| only |

|

|

|

|

|

|

|

|

|

|

|

| Subject to technical modifications | ||

Tool elements

Features - Getting started

Please note: The distance from the object you are working on depends on material and intended method of working. Always try out the airflow and temperature on a test piece first! Using the attachable accessory nozzles (see accessories page on the cover) the flow of hot air can be controlled with maximum precision. Take care when changing hot nozzles! When using the heat gun in the

HG 5010 / HG 5011

The tool is switched ON and OFF at the

HG 6010

The tool is switched ON and OFF at the

HG 6020

The tool is switched ON and OFF at the

Temperature | Temperature | Temperature | Sample | |||

Dial Setting | Range °F | Range °C | Applications | |||

1 | 100 | – 160 °F | 38 | – 71 °C | cleaning surfaces | |

2 | 200 | – 300 °F | 93 | activating adhesives | ||

3 | 375 | – 475 °F | 191 | – 246 °C | shaping/removing flooring materials | |

4 | 475 | – 575 °F | 246 | – 302 °C | welding PE, LDPE, PP, thawing pipes | |

5 | 600 | 316 | – 371 °C | welding ABS, PBT, PC; lap welding plastic sheeting | ||

6 | 725 | – 825 °F | 385 | – 441 | °C | |

7 | 850 | – 950 °F | 454 | – 510 | °C | stripping paint, loosening nuts/screws |

8 | 975 | 524 | – 579 | °C | ||

9 | 1025 | 552 | – 607 °C | soldering | ||

HG 6300

1 | Stainless steel outlet | 4 | Soft stand for stable, | |

2 | Air intake with lattice guard to |

| ||

5 | ||||

| keep out foreign matter | |||

3 | Detachable guard sleeve |

| cord | |

6 | Air flow switch | |||

| (for poorly accessible places) | |||

|

|

|

7Thumbwheel for setting temperature

8Pushbutton for setting temperature

9Temperature monitor LCD

10Soft grip handle for com- fortable operation

The tool is switched ON and OFF at the

Blower stage 1 delivers a temperature of 50 °C. The tool will take a short while to cool to 50 °C after switching down to blower stage 1 when it has been operating at high temperatures on blower stage 2 or 3. While the tool is cooling down, the LCD display (9) shows the actual temperature at the nozzle outlet. After switching off, the tool stays in the last setting. The guard sleeve (3) detaches at a bayonet catch.

CE Declaration of Conformity

This product complies with Low Voltage Directive 06/95/EC, EMC Directive 04/108/EC as well as RoHS Directive 02/95/EC.

- 4 - | - 5 - |