HR2811FT, HR2810, HR2800, HR2811F, HR2810T specifications

The Makita HR2811F is a powerful and efficient rotary hammer drill that’s designed for heavy-duty applications, making it a valuable tool for both professionals and DIY enthusiasts. This model stands out with its robust construction and advanced features that ensure maximum performance and durability.One of the key features of the HR2811F is its powerful 800-watt motor, which delivers an impact energy of up to 2.9 Joules. This impressive power allows the drill to handle even the toughest materials, including concrete and masonry, with ease. The hammer drill is equipped with a dual-mode operation, allowing users to switch between hammering and rotary drilling, making it versatile for various tasks.

The HR2811F incorporates an advanced anti-vibration technology (AVT), which minimizes hand fatigue and enhances user comfort during prolonged use. This technology consists of a counterbalance system that absorbs vibrations, ensuring that the tool operates smoothly and efficiently. Additionally, the soft-grip handle provides added comfort, making it easier to handle while reducing the risk of slips.

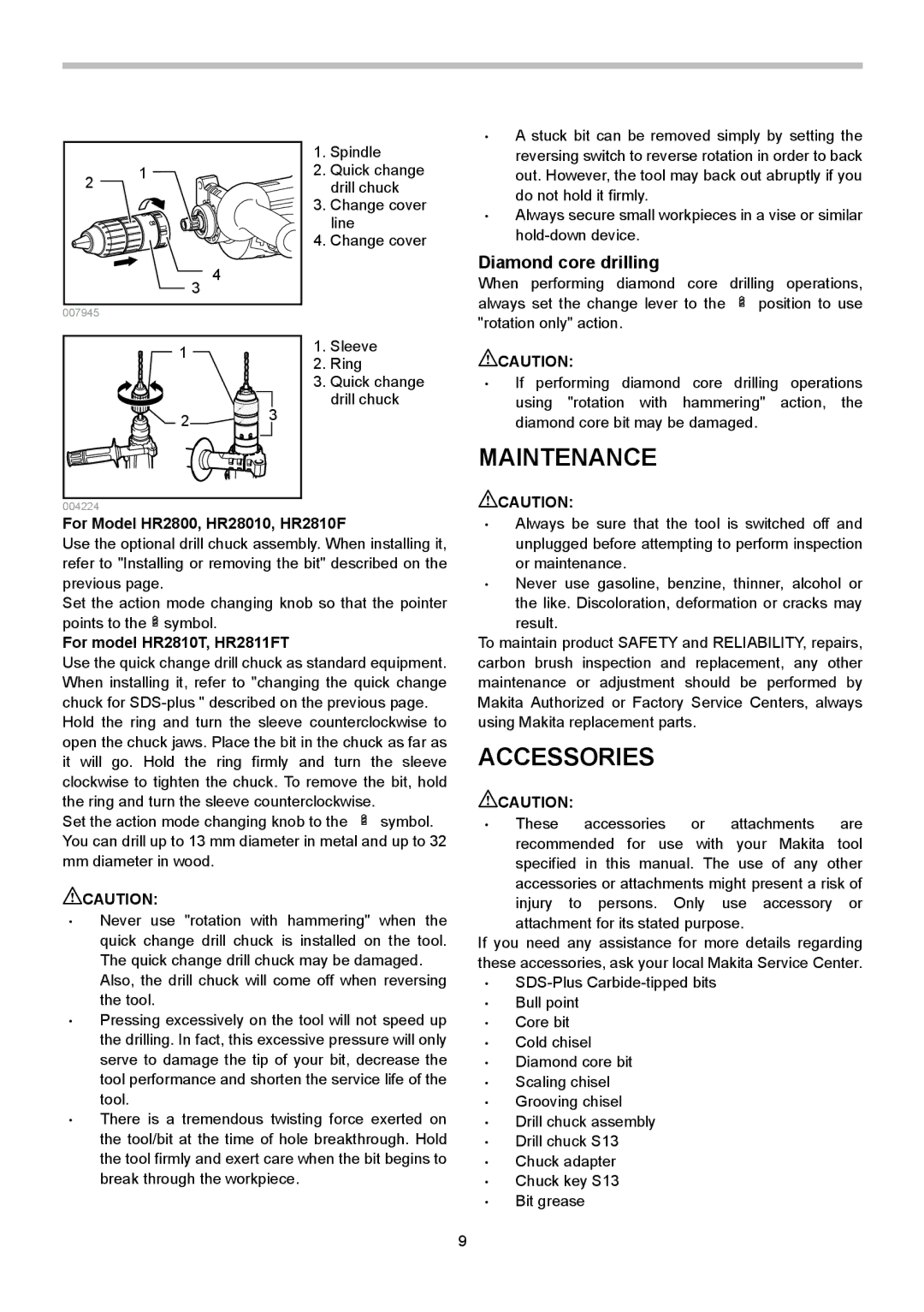

Another notable characteristic of the Makita HR2811F is its optimized dust sealing system, which protects the internal components from dust and debris. This feature significantly enhances the tool's lifespan and reliability, especially when working in challenging environments. The drill is also designed for easy bit changes, with a quick-change chuck system that allows for the rapid exchange of SDS-plus bits.

The HR2811F is equipped with a variable speed control feature that offers users the ability to adjust the speed according to the task at hand. This flexibility is crucial when working on different materials, as it allows for greater precision and improved results. The tool’s lightweight design, combined with its ergonomic shape, makes it easy to maneuver and ideal for overhead applications.

In summary, the Makita HR2811F is a top-tier rotary hammer drill that combines power, comfort, and versatility. With its strong motor, anti-vibration technology, and dust sealing system, it is perfectly suited for demanding tasks in construction and renovation. Whether you're drilling into concrete, brick, or rock, the HR2811F delivers exceptional performance that professionals and hobbyists alike can rely on.