1.1Soldering Iron contains flainmabte g@ (Butane) unLr pressure-use With care.

1.2Do MOT e x p e to heat above t50"C (t120DF)and avoid prolonged exposure to the sun.

1.3Do NOT puncture or incinerate.

1.4Excessive gas flow, flaming or catalyst pulsing red may occur vffwn the regulator is incorrectly adjusted, i.e.. set high. It is essential, therefore, to keep iron away from face and body when igniting.

1.5Do NOT refill, ignite or use near flame, heater, furnace or combustible materials.

1.6KEEPWORK AREA CLEAN. Cluttered areas and benches invite injuries.

1.7KEEP CHILDRENAWAY. All visitors should be keptaway from work area.

1.8STORE IDLE TOOLS. When flat in use, tools should he stored in dry, and high or locked-up places out of rmch of children.

1.9USE SAFETY GLASSES.

1.10 DON'TOVERREACH. Keep proper footing and balance'atall times. | , |

1.11 STAY ALERT. Watch what you are doing. Use common sense. Do not operate tool when you are tired.

1.12DO NOT TOUGH THE HEATED TIP OR BARREL OF THE SOLDERlNGIRON.

1.13DO NOT leave operatinge?Rot soldering iron unalsended.

1.14ALWAYS BE SURE THESOWERING IRON IS COOL BEFORE STORING IT.

1.15DO NOT REPLACE CAP WmfOUT

WITGHJNG OFF AND WSURJNGTIP HAS COOLED. Do ensure flames are extinwished before ning down. If flame does not self extinguish within 30 seconds a new lip is requlreP

1,16 Do U I Iran in a ventdated %a.

1.17Do W T attemot to feadtust or reoair. tttis oroduct is not user serviceable.

tMR#4lM& ThB prbduct, when usedtor soldkng and slmilar applicalions, produces e M & lurown to the State of Californiato cause cancer and birth defects or other repredwtive Nrm.

WARMNG: Tho Departmentof Transportation Hazardous Material Regulationsforbii w~drageof butane or other flammable gas products on passenger aircraft. DOnot pack t h t ttSm ar any other flammable gas item, in any checked or carry-on baggage.

Cont8fm flammable gas under pressure. Do not use near sparks or open flame. I@ aOt ptrnaltte or lnclnerate container or store at temperatures above 120" F. Lep aat Pf rcssch of children.

1.Make sure the gas control ring IS In 'OFFposition.

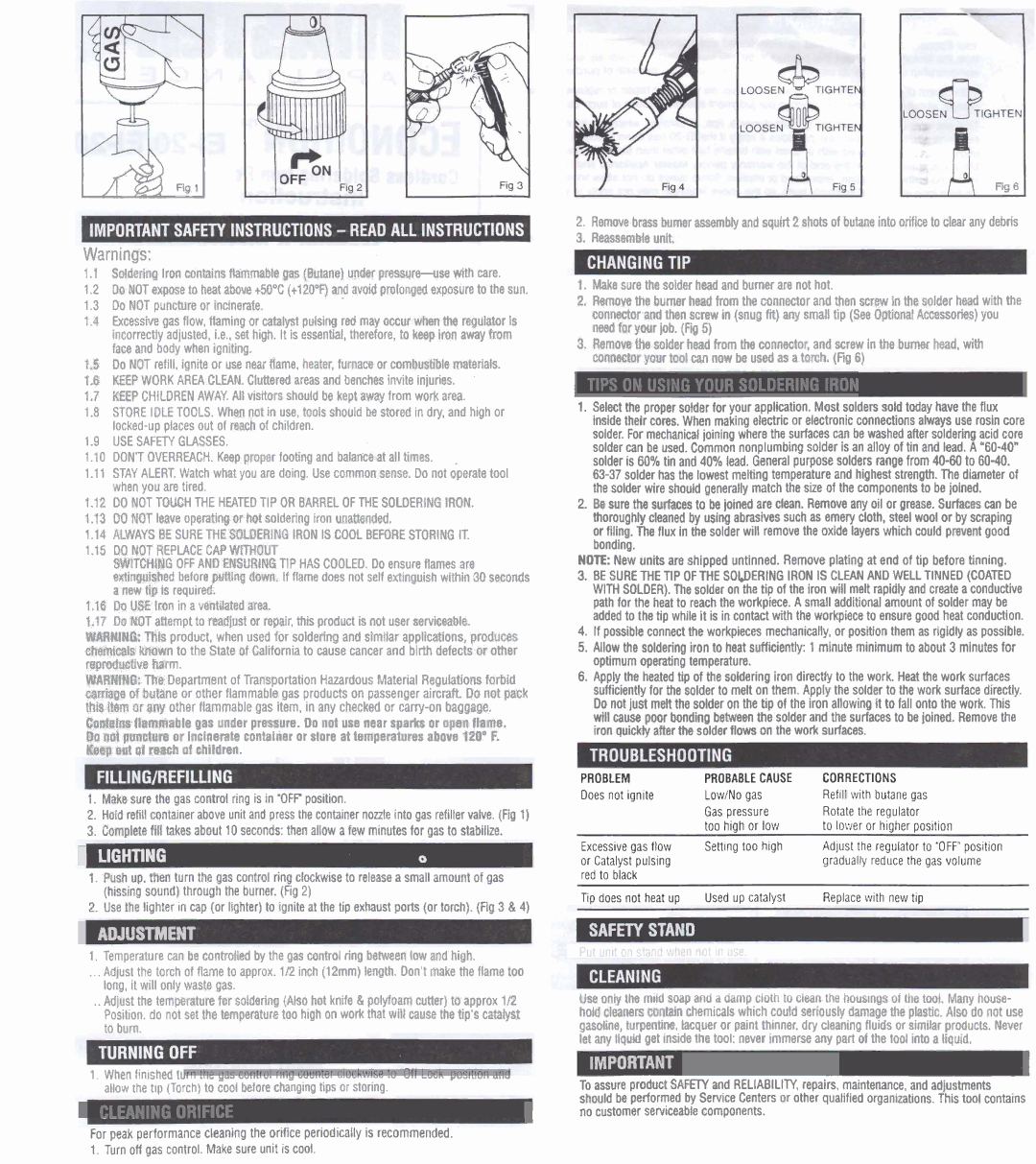

2.Hold refill contalner above unit and press the container nozzle into gas refiller valve. (Fig 1)

3.Complete fill takes about 10 seconds: then allow a few minutes for gas to stabilize.

1.Push up. then turn the gas control ring clockwise to releasea small amount of gas (hissrngsound) through the burner. (Fig 2)

2.Use the lighter ~ncap (or lighter) to Igniteat the tip exhaust ports (or torch). (Fig 3 & 4)

1.Make sure the solder head and burner are not hot.

2.Remove the burner headfrom the connector and Fen s c m in the solder headwith the connector and then screw in (snug fit)any small tlp (See Opllonal Accessories) you need fur your job. (Fig 5)

3.Refnowetllesolder head from the conneotor, and screw in the burner head, with eolmmr your tool can now be used as a t~rch.(FQ6)

I | | I |

TIPS ON USING YOUR SOLDERING IRON |

|

1.Select the proper solder for your application. Most solders sold today have the flux inside their cores. When makina electric or electronic connectionsalways use rosin core solder. For mechanical joining where the surfaces can be washed after Gldering acid core solder can be used. Common nonplumbing solder is an alloy of tin and lead. A "60-40" solder is 60% tin and 40% lead. General purposesolders range from 40-60 to 60-40.

63-37 solder has the lowest melting temperatureand highest strength. The diameter of the solder wire should generally match the slze of the componentsto be joined.

2.Be sure the surfaces to be joined are clean. Remove any oil or grease. Surfaces can be thoroughly cleaned by using abrasives such as emery cloth, steel wool or by scraping or filing. The flux in the solder will remove the oxide layers which could prevent good bonding.

NOTE: New units are shipped untinned. Remove plating at end of tip before tinning.

3.BE SURE THE TIP OF THE SOl.DERlNG IRON IS CLEAN AND,WELL TINNED (COATED WITH SOLDER). The solder on the ti0 of the iron w~llmelt raoldlv and create a conductive

path for thehkt to;&$ the work$ece. A small additional'ambuntof solder may be added to the tip while it is in contact with the workpiece to ensure good heat conduction.

4.If possible connect the workpieces mechanically, or positionthem as rigidly as possible.

5.Allow the soldering iron to heat sufficiently: 1 minute minimumto about 3 minutes for optimum operating temperature.

6.Apply the heated tip of the soldering iron directly to the work. Heat the work surfaces sufficientlv for the solder to melt on them. Aoolv the solder to the work surface directlv. Do not juit melt the solder on the tip of the irori allowingit to fall onto the work. This ' will cause poor bonding betweenthe solder and the surfaces to be joined. Remove the iron quickly after the solder flows on the work surfaces.

PROBLEM | PROBABLE CAUSE | CORRECTIONS |

Does not ~gn~te | LorviNo gas | Ref~llwlth butane gas |

| Gas pressure | Rotate the regulator |

| too hlgh or lovi | to lower or h~gherposltlon |

Excessive gas flow | Sen~ngtoo hlgh | Adjust the regulator to 'OFF'pos~t~on |

or Catalyst pulsing | | gradually reduce the gas volume |

red to black | | |

TIP does not heat up | Used up catalyst | Replace w~thnew t ~ p |