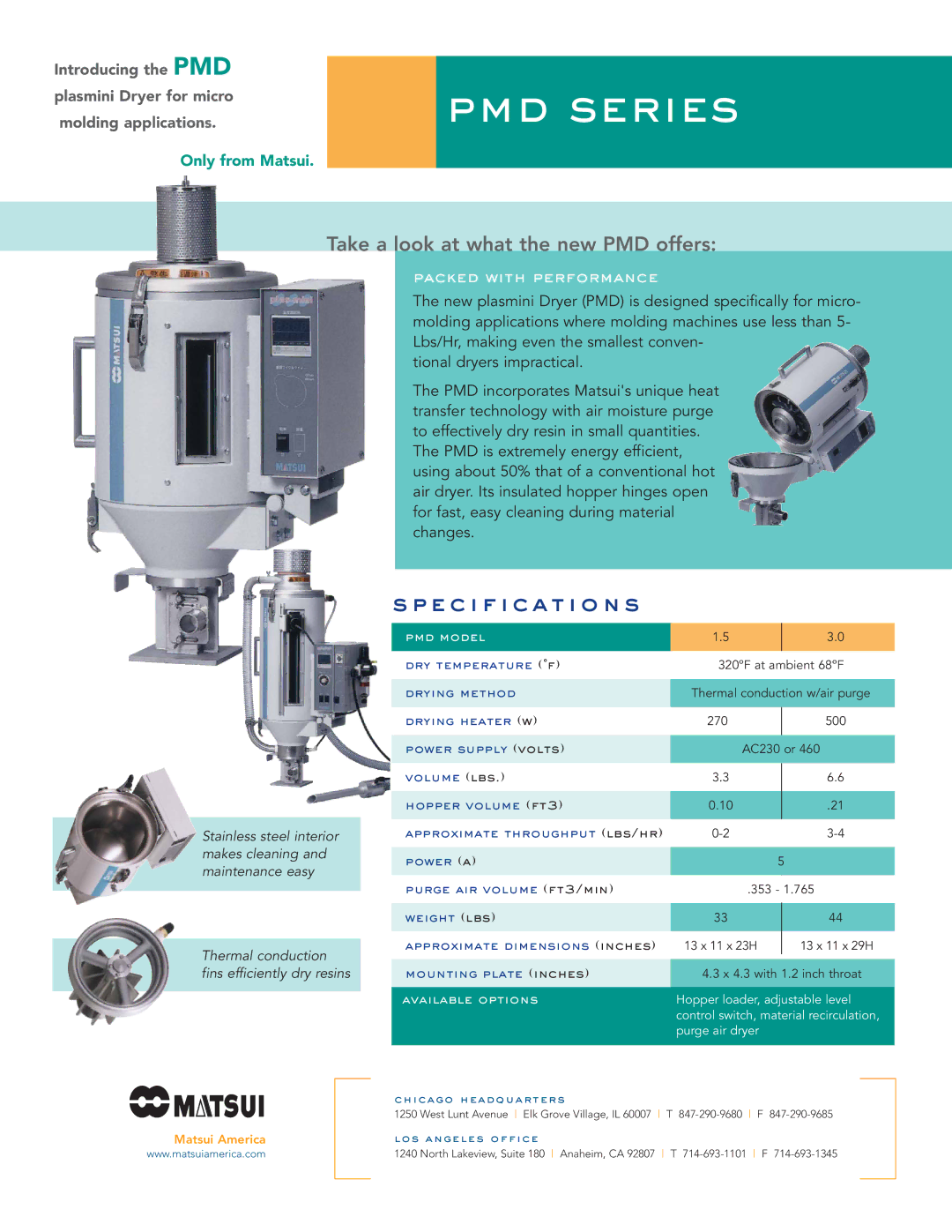

PMD Series specifications

Matsui America has established itself as a key player in the field of plastics processing with its innovative PMD Series. This series is designed to enhance productivity, reliability, and energy efficiency in the manufacturing process. At the core of the PMD Series are advanced features that cater to the diverse needs of various industries, including automotive, consumer products, and electronics.One of the standout characteristics of the Matsui PMD Series is its precision temperature control system. This cutting-edge technology ensures that the material is maintained at optimal temperatures, which reduces waste and improves overall part quality. By effectively managing the temperature during the processing phase, manufacturers can achieve better consistency in the final product and minimize defects caused by thermal fluctuations.

In addition to temperature control, the PMD Series features an integrated data logging system. This innovative technology provides real-time monitoring and analysis of production metrics, allowing operators to identify trends and make informed decisions that enhance efficiency. This transparency not only aids in troubleshooting but also supports continuous improvement initiatives across the production line.

The PMD Series is built with energy efficiency in mind. Its design employs advanced motors and drives that significantly reduce energy consumption without sacrificing performance. This focus on sustainability is particularly relevant in today’s manufacturing landscape, where companies are increasingly seeking ways to decrease their carbon footprint and operational costs.

Furthermore, the Matsui PMD Series is known for its user-friendly interface. The intuitive controls simplify operation and make it easier for staff to adapt to the technology, ensuring that manufacturers can achieve high levels of productivity with minimal training. This is critical in fast-paced environments where production needs may fluctuate.

Finally, the robust construction of the PMD Series ensures durability and long-term reliability. Matsui America prioritizes quality in its manufacturing processes, which means that users can depend on their equipment for consistent performance over time.

In conclusion, the Matsui America PMD Series stands out due to its focus on precision, data integration, energy efficiency, user-friendliness, and durability. This combination of features positions the PMD Series as a valuable asset for manufacturers looking to optimize their operations and enhance their competitiveness in the market. As industries evolve, the PMD Series demonstrates Matsui America's commitment to innovation and excellence in plastics processing technology.