![]() Start throttle button

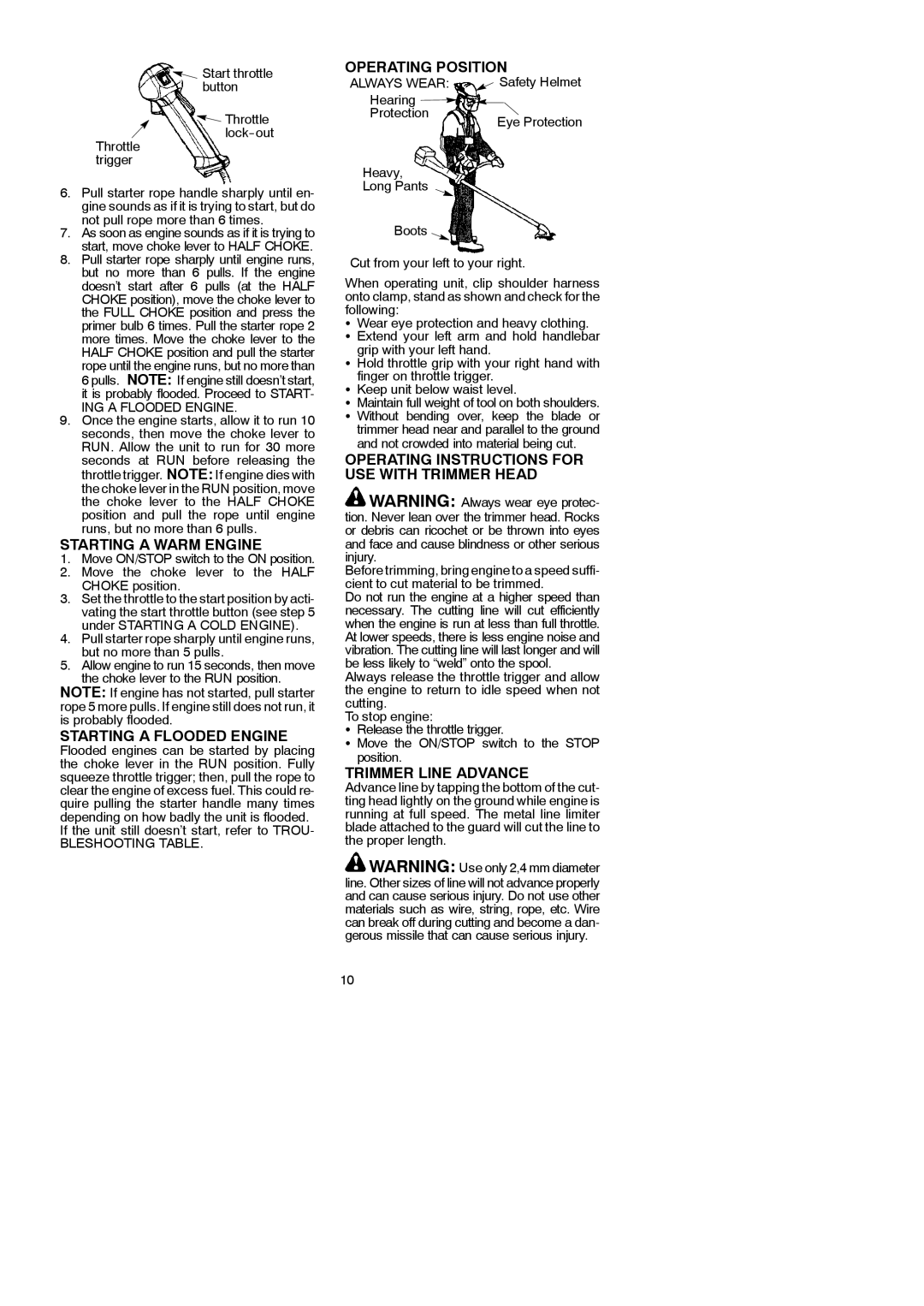

Start throttle button

Throttle

Throttle lock--out

Throttle trigger

6.Pull starter rope handle sharply until en- gine sounds as if it is trying to start, but do not pull rope more than 6 times.

7.As soon as engine sounds as if it is trying to start, move choke lever to HALF CHOKE.

8.Pull starter rope sharply until engine runs, but no more than 6 pulls. If the engine doesn’t start after 6 pulls (at the HALF CHOKE position), move the choke lever to the FULL CHOKE position and press the primer bulb 6 times. Pull the starter rope 2 more times. Move the choke lever to the HALF CHOKE position and pull the starter rope until the engine runs, but no more than 6 pulls. NOTE: If engine still doesn’t start, it is probably flooded. Proceed to START-

ING A FLOODED ENGINE.

9.Once the engine starts, allow it to run 10 seconds, then move the choke lever to RUN. Allow the unit to run for 30 more seconds at RUN before releasing the throttle trigger. NOTE: If engine dies with the choke lever in the RUN position, move the choke lever to the HALF CHOKE position and pull the rope until engine runs, but no more than 6 pulls.

STARTING A WARM ENGINE

1.Move ON/STOP switch to the ON position.

2.Move the choke lever to the HALF CHOKE position.

3.Set the throttle to the start position by acti- vating the start throttle button (see step 5 under STARTING A COLD ENGINE).

4.Pull starter rope sharply until engine runs, but no more than 5 pulls.

5.Allow engine to run 15 seconds, then move the choke lever to the RUN position.

NOTE: If engine has not started, pull starter rope 5 more pulls. If engine still does not run, it is probably flooded.

STARTING A FLOODED ENGINE

Flooded engines can be started by placing the choke lever in the RUN position. Fully squeeze throttle trigger; then, pull the rope to clear the engine of excess fuel. This could re- quire pulling the starter handle many times depending on how badly the unit is flooded. If the unit still doesn’t start, refer to TROU-

BLESHOOTING TABLE.

OPERATING POSITION

ALWAYS WEAR: | Safety Helmet |

Hearing |

|

Protection | Eye Protection |

|

Heavy,

Long Pants

Boots

Cut from your left to your right.

When operating unit, clip shoulder harness onto clamp, stand as shown and check for the following:

SWear eye protection and heavy clothing. S Extend your left arm and hold handlebar

grip with your left hand.

S Hold throttle grip with your right hand with finger on throttle trigger.

S Keep unit below waist level.

S Maintain full weight of tool on both shoulders. S Without bending over, keep the blade or trimmer head near and parallel to the ground and not crowded into material being cut.

OPERATING INSTRUCTIONS FOR USE WITH TRIMMER HEAD

![]() WARNING: Always wear eye protec- tion. Never lean over the trimmer head. Rocks or debris can ricochet or be thrown into eyes and face and cause blindness or other serious injury.

WARNING: Always wear eye protec- tion. Never lean over the trimmer head. Rocks or debris can ricochet or be thrown into eyes and face and cause blindness or other serious injury.

Before trimming, bring engine to a speed suffi- cient to cut material to be trimmed.

Do not run the engine at a higher speed than necessary. The cutting line will cut efficiently when the engine is run at less than full throttle. At lower speeds, there is less engine noise and vibration. The cutting line will last longer and will be less likely to “weld” onto the spool.

Always release the throttle trigger and allow the engine to return to idle speed when not cutting.

To stop engine:

SRelease the throttle trigger.

S Move the ON/STOP switch to the STOP position.

TRIMMER LINE ADVANCE

Advance line by tapping the bottom of the cut- ting head lightly on the ground while engine is running at full speed. The metal line limiter blade attached to the guard will cut the line to the proper length.

![]() WARNING: Use only 2,4 mm diameter line. Other sizes of line will not advance properly and can cause serious injury. Do not use other materials such as wire, string, rope, etc. Wire can break off during cutting and become a dan- gerous missile that can cause serious injury.

WARNING: Use only 2,4 mm diameter line. Other sizes of line will not advance properly and can cause serious injury. Do not use other materials such as wire, string, rope, etc. Wire can break off during cutting and become a dan- gerous missile that can cause serious injury.

10