IMPACT DRILLS

THE WORKSHOP ALL-ROUNDERS.

Impact drills have a number of uses. In hammer mode they come into their own when drilling ≤ 12 mm Ø bits into stone, concrete or brick. In rotary only mode they are ideal for drilling into wood, metal, plastics and even glass.

With the right attachments they can be used for driving in screws, stirring paint/plaster/mortor, polishing, sanding, grinding metal or removing rust. Metabo – Designed for Life.

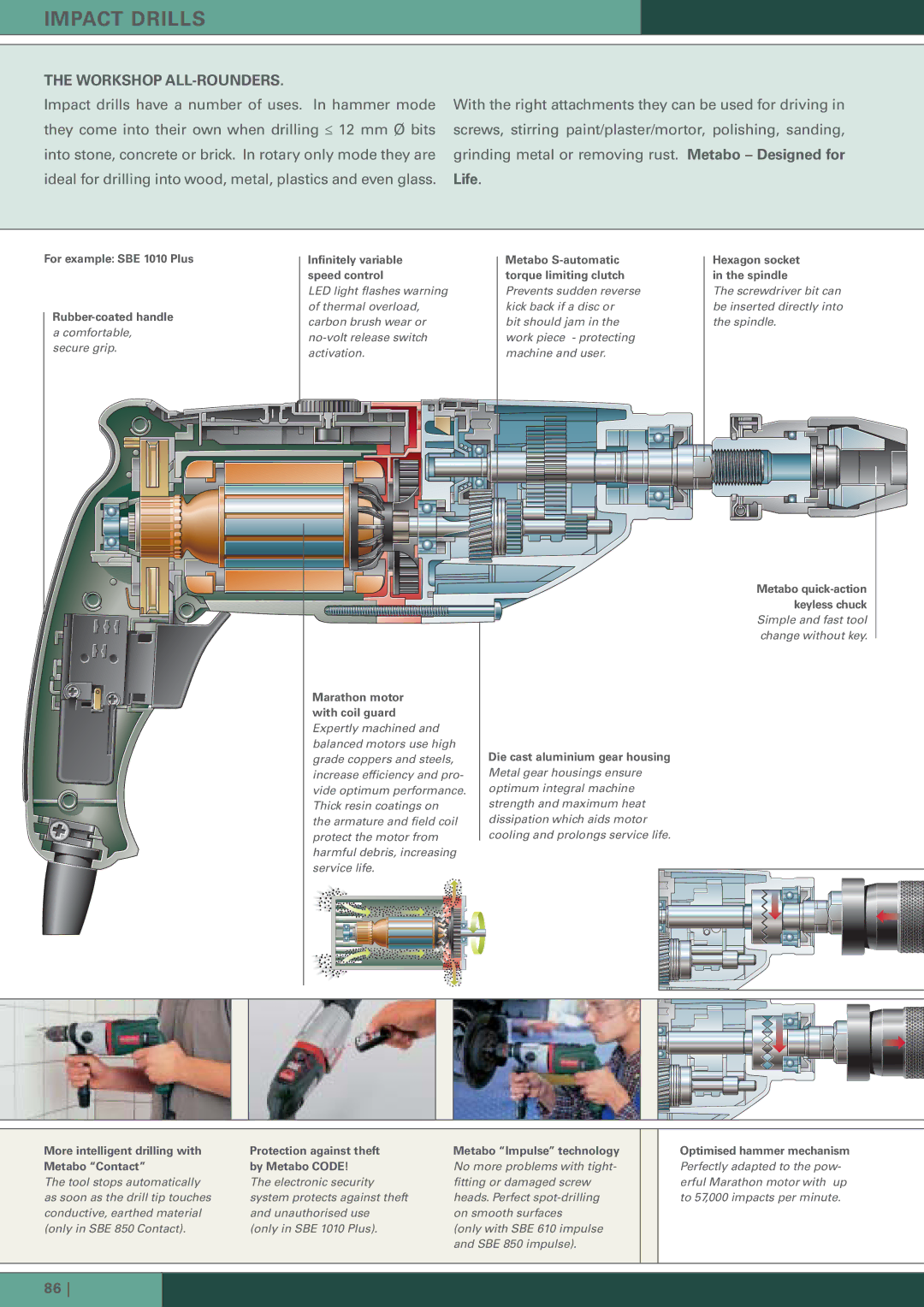

For example: SBE 1010 Plus

Rubber-coated handle

acomfortable, secure grip.

Infinitely variable speed control

LED light flashes warning of thermal overload, carbon brush wear or

Marathon motor with coil guard

Expertly machined and balanced motors use high grade coppers and steels, increase efficiency and pro- vide optimum performance. Thick resin coatings on the armature and field coil protect the motor from harmful debris, increasing service life.

Metabo S-automatic torque limiting clutch

Prevents sudden reverse kick back if a disc or

bit should jam in the work piece - protecting machine and user.

Die cast aluminium gear housing

Metal gear housings ensure optimum integral machine strength and maximum heat dissipation which aids motor cooling and prolongs service life.

Hexagon socket in the spindle

The screwdriver bit can be inserted directly into the spindle.

Metabo |

keyless chuck |

Simple and fast tool |

change without key. |

More intelligent drilling with | Protection against theft | Metabo “Impulse” technology |

|

Metabo “Contact” | by Metabo CODE! | No more problems with tight- |

|

The tool stops automatically | The electronic security | fitting or damaged screw |

|

as soon as the drill tip touches | system protects against theft | heads. Perfect |

|

conductive, earthed material | and unauthorised use | on smooth surfaces |

|

(only in SBE 850 Contact). | (only in SBE 1010 Plus). | (only with SBE 610 impulse |

|

|

| and SBE 850 impulse). |

|

|

|

|

|

Optimised hammer mechanism

Perfectly adapted to the pow- erful Marathon motor with up to 57,000 impacts per minute.

86