These ‘C’ Channel brackets are installed in the vertical plane using existing screws (Item 6) to support these ‘C’ Channels using the upper and lower Key Hole openings in the ‘C’ Channels. The ‘C’ Channels are identical and once installed will allow ample amounts of air through the cooling fan mounted on the rear side of the ovem by keeping the oven away from the rear wall.

If you have any questions about how to mount these two ‘C’ Channel brackets, kindly phone Middleby Technical

Services at

III.ELECTRICAL CONNECTION INFORMATION FOR

WARNING

Authorized supplier personnel normally ac- complish the connections for the ventilation system, electric supply, as arranged by the customer. Following these connections, the

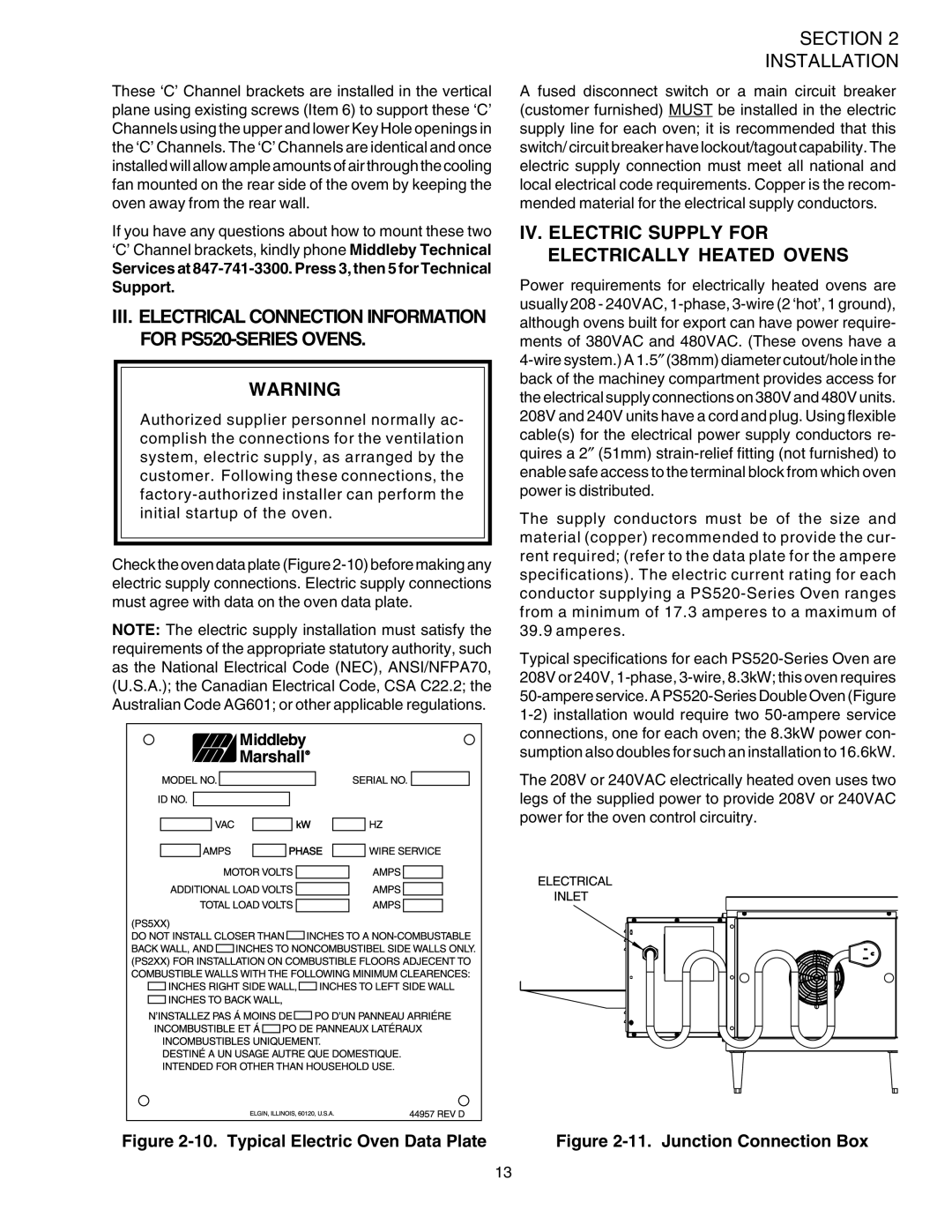

Check the oven data plate (Figure

NOTE: The electric supply installation must satisfy the requirements of the appropriate statutory authority, such as the National Electrical Code (NEC), ANSI/NFPA70, (U.S.A.); the Canadian Electrical Code, CSA C22.2; the Australian Code AG601; or other applicable regulations.

SECTION 2

INSTALLATION

A fused disconnect switch or a main circuit breaker (customer furnished) MUST be installed in the electric supply line for each oven; it is recommended that this switch/ circuit breaker have lockout/tagout capability. The electric supply connection must meet all national and local electrical code requirements. Copper is the recom- mended material for the electrical supply conductors.

IV. ELECTRIC SUPPLY FOR ELECTRICALLY HEATED OVENS

Power requirements for electrically heated ovens are usually 208 - 240VAC,

The supply conductors must be of the size and material (copper) recommended to provide the cur- rent required; (refer to the data plate for the ampere specifications). The electric current rating for each conductor supplying a

Typical specifications for each

The 208V or 240VAC electrically heated oven uses two legs of the supplied power to provide 208V or 240VAC power for the oven control circuitry.

Figure | Figure |

13