PS724E specifications

The Middleby Marshall PS724E is a revolutionary conveyor oven designed to meet the high demands of commercial kitchens while ensuring superior cooking quality and efficiency. Its innovative design incorporates advanced technologies that deliver exceptional performance, making it a top choice for restaurants, pizzerias, and other food service environments.One of the main features of the PS724E is its unique dual conveyor system that allows for even cooking. The oven utilizes a patented air impingement technology, which pushes heated air onto the food items for faster cooking times and consistent results. This technology ensures that every dish, from pizzas to casseroles, is cooked evenly and effectively. The conveyor belt operates smoothly, allowing chefs to load and unload products easily without compromising speed.

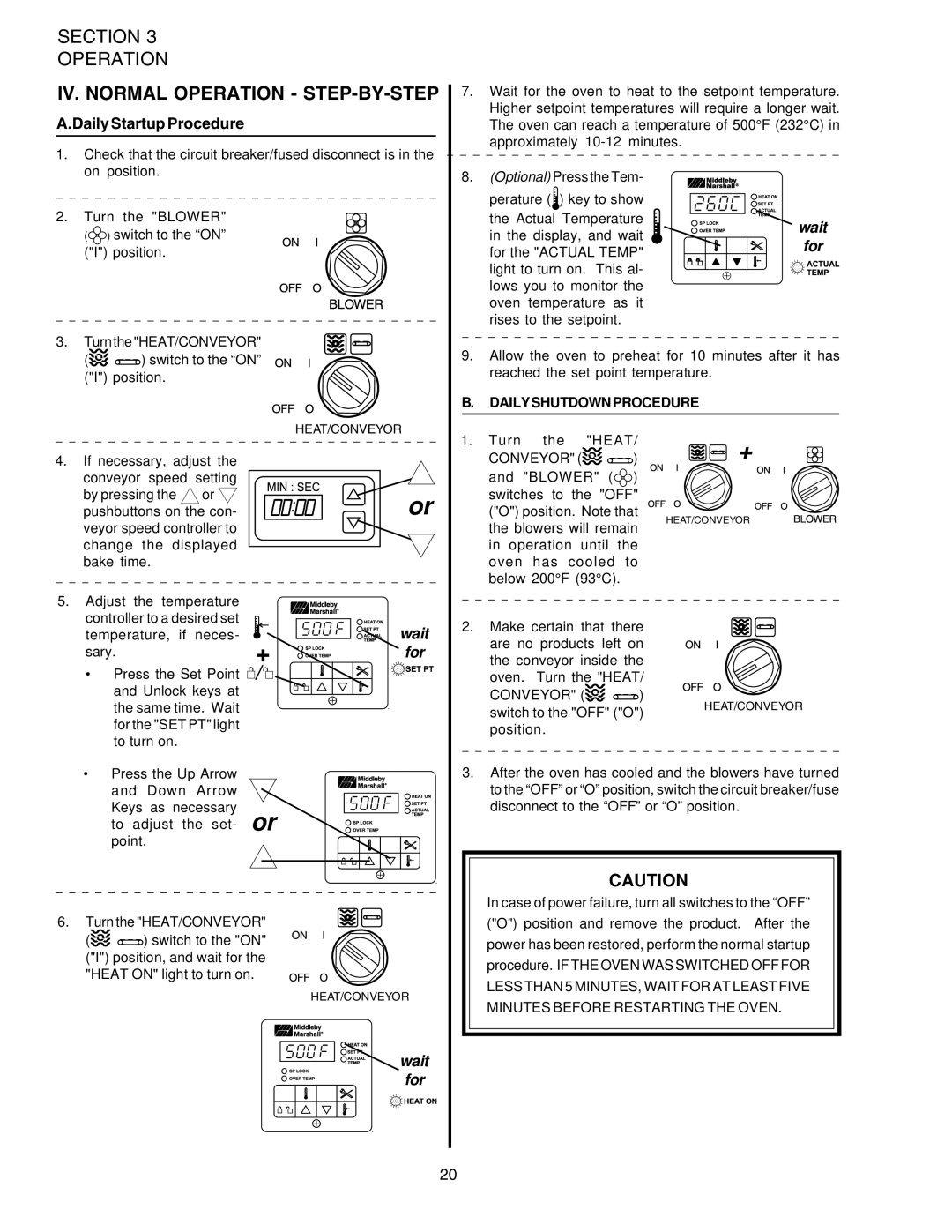

The PS724E is equipped with an advanced digital control system that provides precise temperature settings and cooking times. This system allows operators to program specific cooking profiles for different menu items, ensuring consistent quality while reducing the risk of human error. With easy-to-read displays, staff can monitor cooking status at a glance, streamlining the workflow in busy kitchens.

Another defining characteristic of the PS724E is its energy efficiency. This model is designed to consume less energy than traditional ovens, making it a sustainable choice for businesses looking to reduce their operating costs. The insulation and airflow technologies used in this oven not only maintain high cooking temperatures but also minimize heat loss, contributing to its low energy consumption.

The oven's construction is robust and durable, built to withstand the rigors of a busy kitchen environment. Its stainless steel exterior not only adds a sleek aesthetic appeal but also ensures easy cleaning and maintenance. The ergonomic design of the conveyor makes it user-friendly, promoting safety while enhancing the overall cooking experience.

In summary, the Middleby Marshall PS724E is an innovative conveyor oven that combines advanced cooking technology, energy efficiency, and user-friendly features. With its dual conveyor system, digital control capabilities, and durable construction, it represents a significant advancement in commercial cooking equipment. This oven is perfectly suited for high-volume operations, offering reliability and consistency while helping to elevate food quality to new heights. Whether used for baking pizzas, roasting meats, or crafting baked goods, the PS724E is an invaluable asset for any modern kitchen.