Blue Star® | Series | ||

| Industrial Applications | Processes | |

| |||

| Maintenance | Stick (SMAW) | |

| Quick | Repair | DC TIG (GTAW) | |

Farm/Ranch Applications | Air Plasma Cutting and Gouging | ||

| |||

| Specs | Construction | with optional Spectrum models | |

| |||

|

|

| |

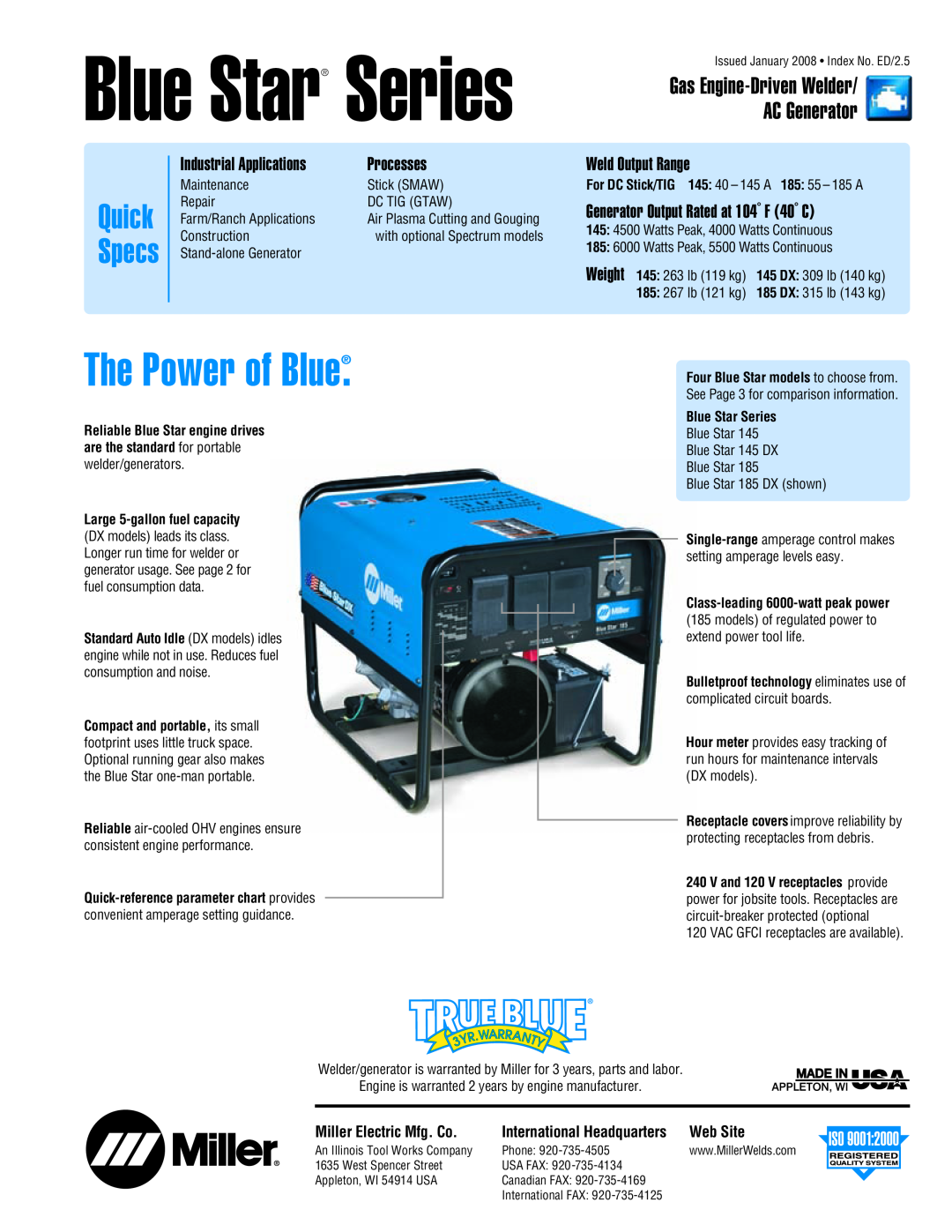

The Power of Blue®.

Reliable Blue Star engine drives are the standard for portable welder/generators.

Large

Standard Auto Idle (DX models) idles engine while not in use. Reduces fuel consumption and noise.

Compact and portable, its small footprint uses little truck space. Optional running gear also makes the Blue Star

Reliable

Issued January 2008 • Index No. ED/2.5

Gas Engine-Driven Welder/

AC Generator

Weld Output RangeFor DC Stick/TIG 145: 40 – 145 A 185: 55 – 185 AGenerator Output Rated at 104˚ F (40˚ C)145:4500 Watts Peak, 4000 Watts Continuous

185:6000 Watts Peak, 5500 Watts Continuous

Weight 145: 263 lb (119 kg) 145 DX: 309 lb (140 kg)

185:267 lb (121 kg) 185 DX: 315 lb (143 kg)

Four Blue Star models to choose from.See Page 3 for comparison information.

Blue Star SeriesBlue Star 145

Blue Star 145 DX

Blue Star 185

Blue Star 185 DX (shown)

Hour meter provides easy tracking of run hours for maintenance intervals (DX models).

Receptacle covers improve reliability by protecting receptacles from debris.

240 V and 120 V receptacles provide power for jobsite tools. Receptacles are

120 VAC GFCI receptacles are available).

Welder/generator is warranted by Miller for 3 years, parts and labor.

Engine is warranted 2 years by engine manufacturer.

Miller Electric Mfg. Co. | International Headquarters | Web Site |

An Illinois Tool Works Company | Phone: | www.MillerWelds.com |

1635 West Spencer Street | USA FAX: |

|

Appleton, WI 54914 USA | Canadian FAX: |

|

| International FAX: |

|